Data storage device and method of production therefor

a data storage and data technology, applied in the field of data storage devices, can solve problems such as the reduction of the signal-to-noise ratio (snr) ratio, and achieve the effect of lowering the shear modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Within the description, the same reference numerals or signs are used to denote the same parts or the like.

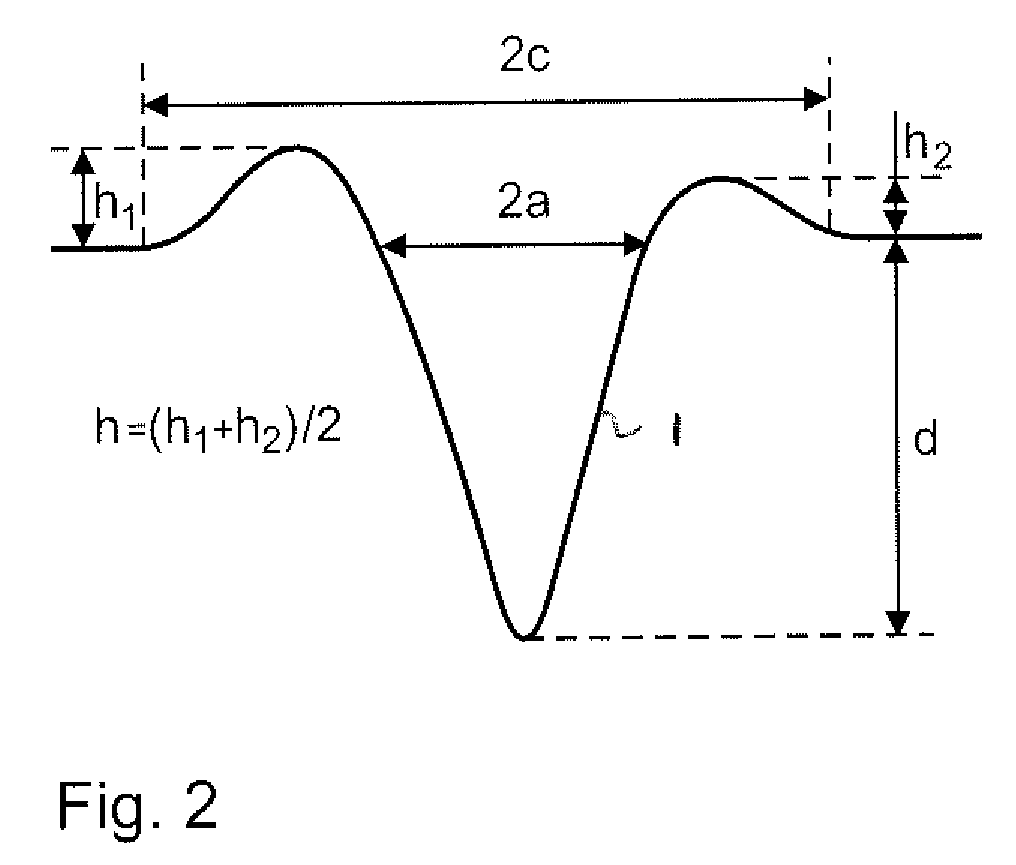

[0024]As described above, bits are encoded in a data storage medium comprising a polymer layer in the form of indentation marks, each representing a logical “1”, and non-indentation marks, each representing a logical “0”. By way of example, FIG. 2 schematically illustrates a typical profile of an indentation mark 1 formed in a polymer layer. As can be seen from FIG. 2, the indentation mark 1 is a trough formed in the polymer layer having a depth d and inner diameter 2a. Polymer material that is displaced during formation of the indentation mark 1 is deposited in the region surrounding the opening of the indentation mark 1, thereby to form a rim. Displacement of the polymer material typically occurs in a non-uniform manner. In this case, the rim profile would be asymmetric, this being depicted in FIG. 2 by way of the respective heights h1 and h2 of the rim formed around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com