Apparatus for tilting away a part of a signature to be separated from a rack

a technology of a rack and a signature, which is applied in the direction of article separation, pile separation, thin material handling, etc., can solve the problem of not always being vaccinated, and achieve the effect of simple manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

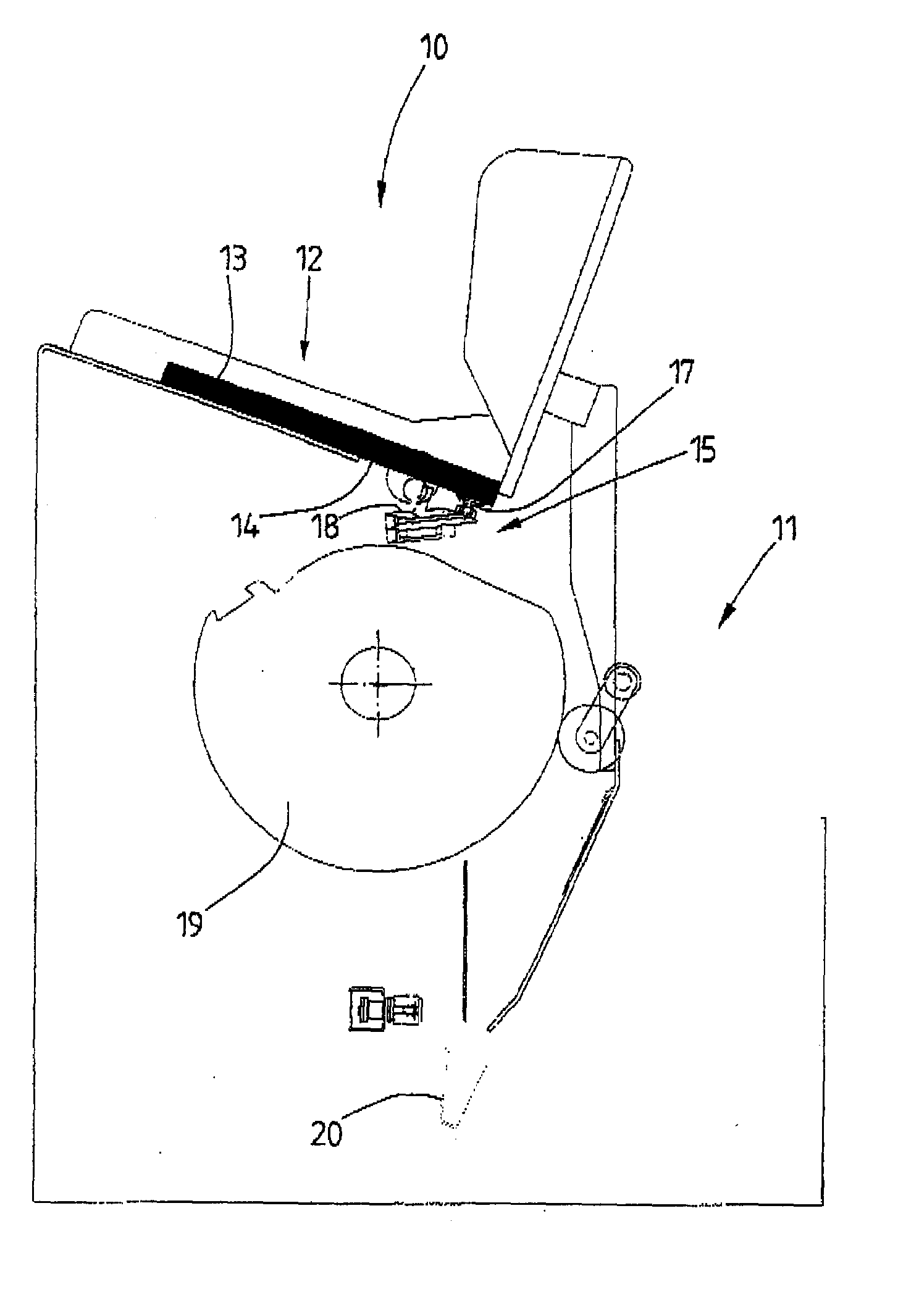

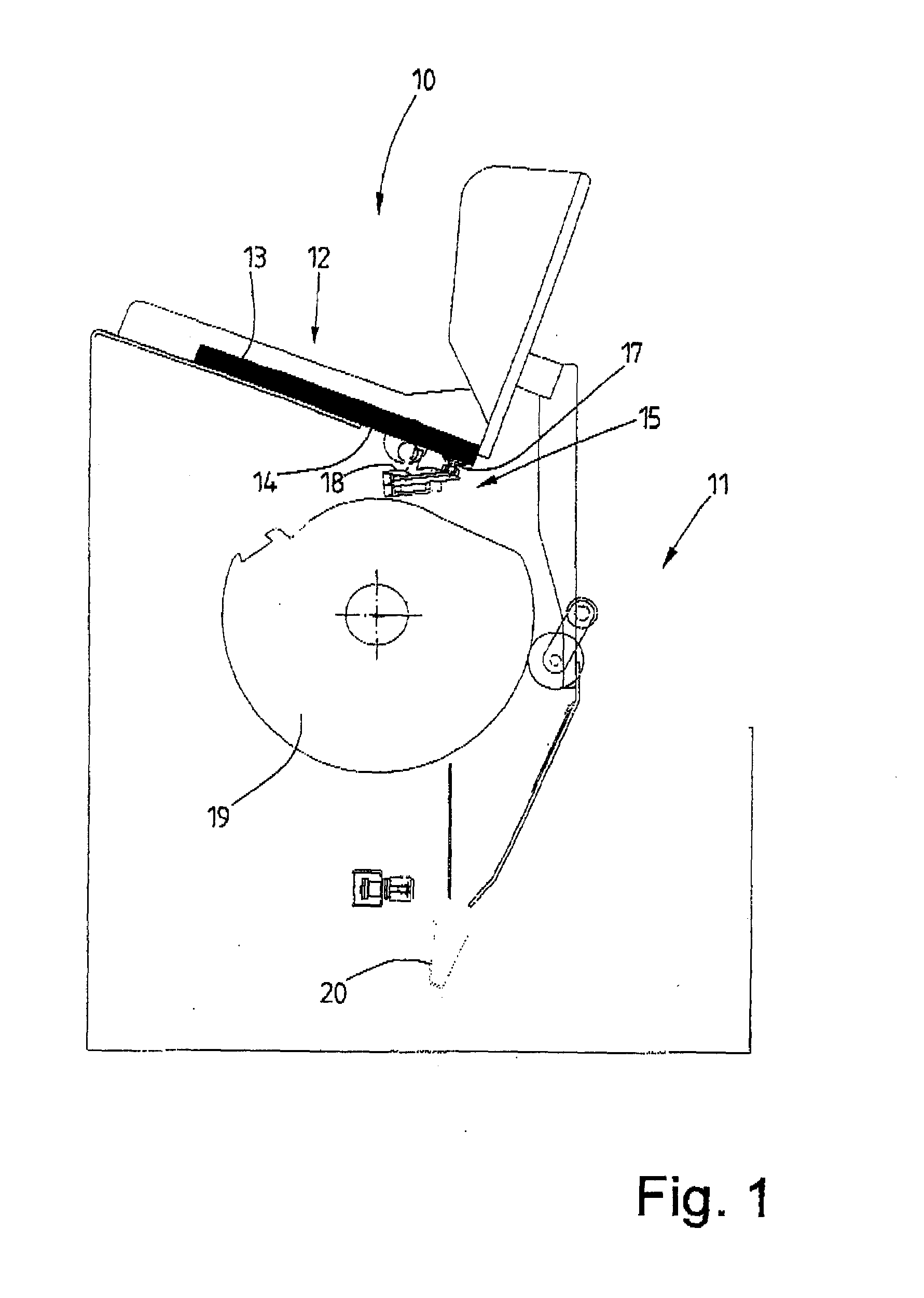

[0022]The invention relates to the field of print further processing. Here, these are devices such as collating machines, adhesive binders or cover feeders. FIG. 1 shows a part of a collating machine 10 in simplified form, namely only one feed station 11 of the collating machine 10 is shown. The feed station 11 has a magazine 12 for accommodating a stack 13 of signatures which lie one above the other, which are folded sheets 14 in the present case. The folded sheets 14 of the stack 13 are separated in the region of the feed station 11, by a lowermost folded sheet 14 being pulled off from under the magazine 12 gradually.

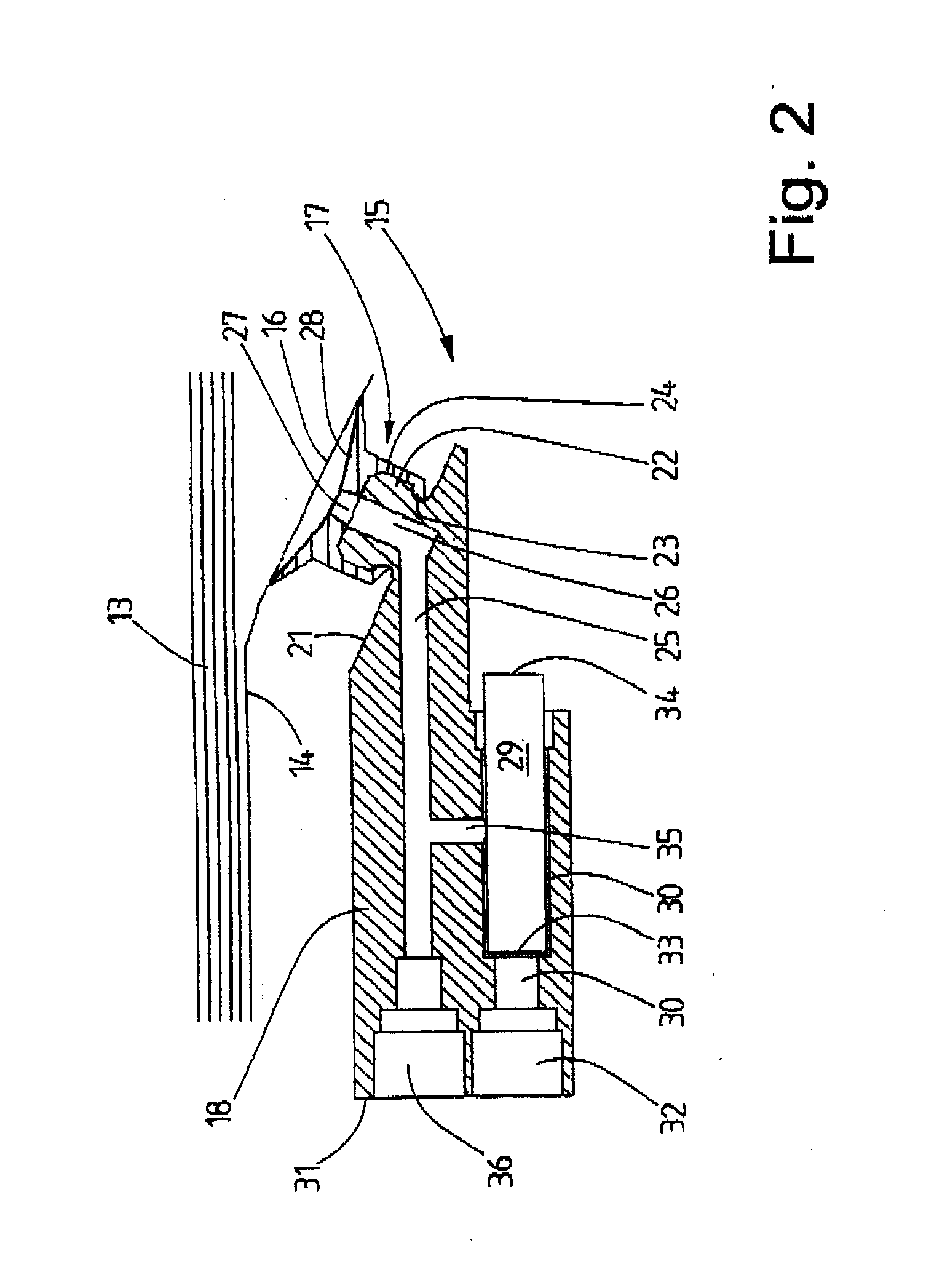

[0023]The respectively lowermost folded sheet 14 of the stack 13 is separated in a first step by the apparatus according to the invention which is configured as a tilting sucker 15 in the collating machine 10 which is shown here. An edge region 16 (it also being possible for it to be only a corner region) of the lowermost folded sheet 14 is tilted away from the stack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com