Graphite product and its fabrication method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

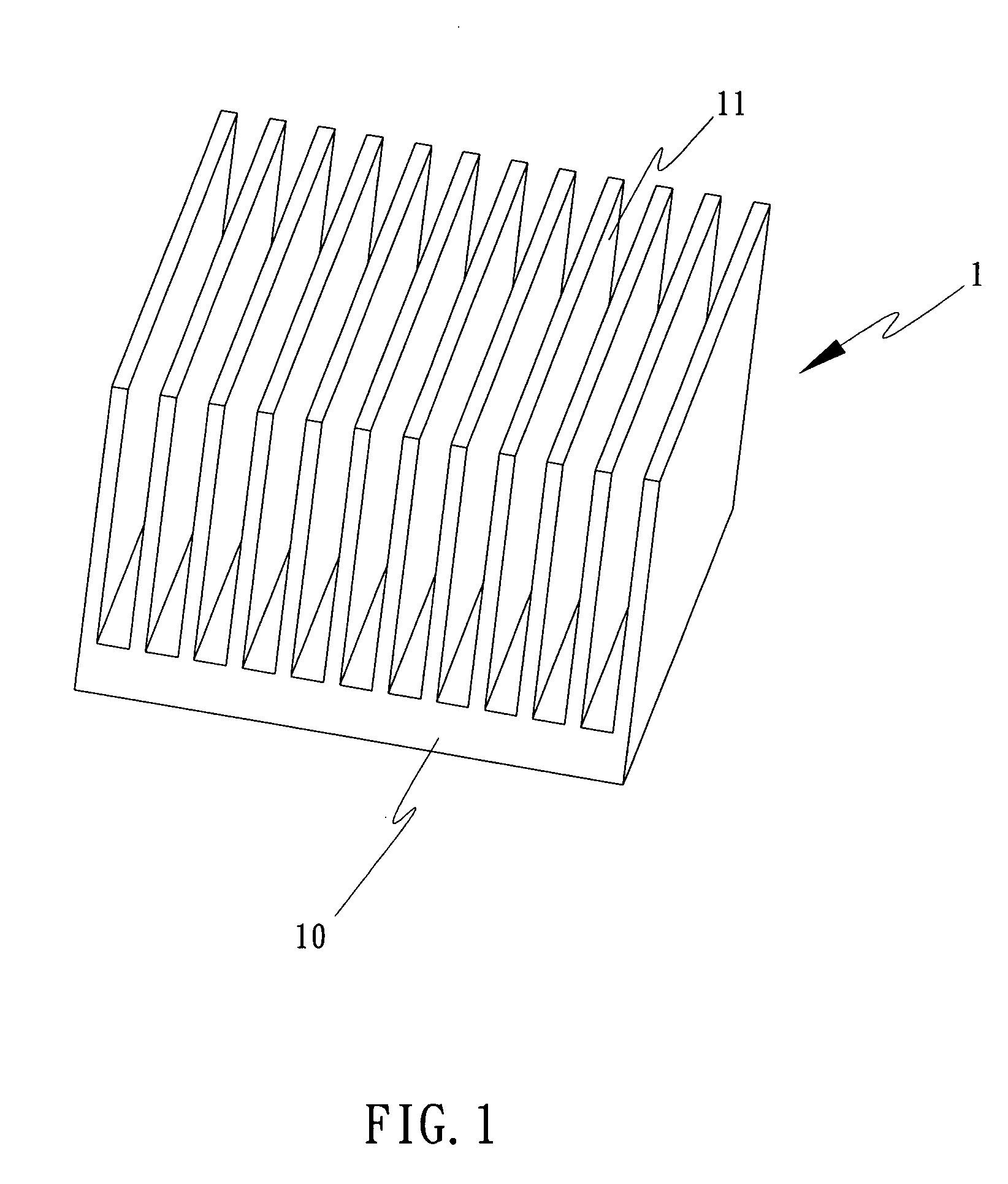

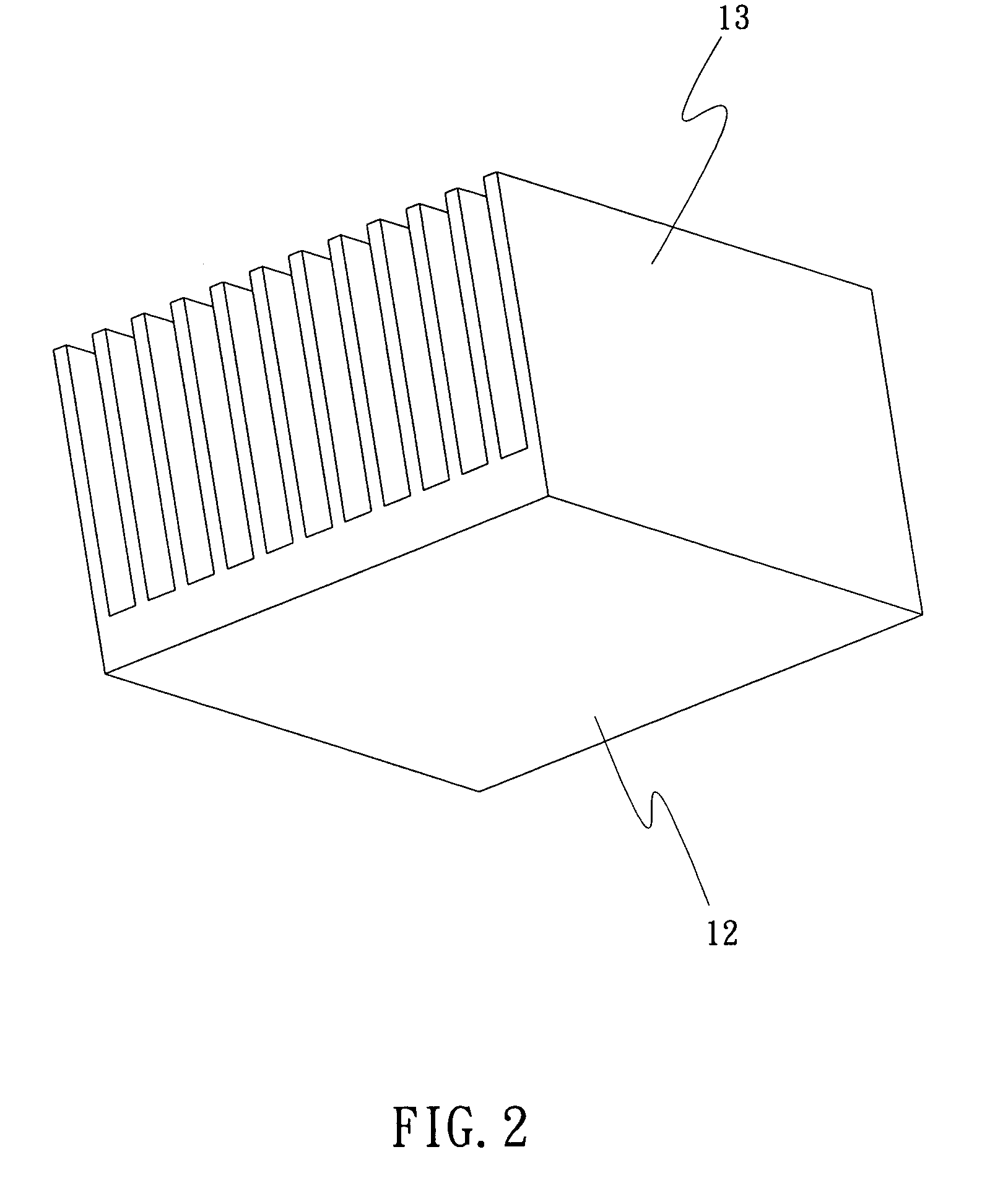

[0012] Referring to FIGS. 1 and 2, a graphite product in accordance with the present invention is a heat sink. The heat sink has a graphite body 1 and a metal coating (not shown) on the surface of the graphite body 1. The graphite body 1 has a flat base 10 and a plurality of radiating fins 11 arranged at the top side of the flat base 10. The bottom surface of the graphite body 1 is a heat transferring surface 12 for transferring heat from an electronic or semiconductor device. The other surface of the graphite body 1 forms a heat dissipation surface 13 adapted to dissipate heat into the outside open air. According to this embodiment, the metal coating is covered on the heat dissipation surface 13 (It is workable that the metal coating covers the whole surface of the graphite body 1). The metal coating can be formed of copper, gold, or aluminum. According to this embodiment, the metal coating is formed of copper and covered on the heat dissipation surface 13 of the graphite body 1 by...

second embodiment

[0013]FIG. 3 shows an electric connector constructed in accordance with the present invention and connected to a matching electric connector (or an electronic apparatus). The electric connector comprises an electrically insulative housing 2, and a plurality of conducting terminals 21 mounted in the housing 2. The conducting terminals 21 are made out of graphite and peripherally covered with a layer of copper coating. The conducting terminals 21 have a cylindrical shape, and are kept in contact with respective conducting terminals 31 of a matching electric connector (or electronic apparatus). The copper coating coated on the surface of each conducting terminal 21 enhances the conductivity and prevents dispersion of graphite powder dust, thereby maintaining the nice outer looking of the respective conducting terminal.

[0014] Referring to FIG. 4, a graphite product fabrication method in accordance with the present invention includes the steps of (1) using a mold to mold graphite into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com