Multifunctional optical assembly

a multi-functional, optical technology, applied in the field of optical assemblies, can solve the problems of inconsistencies in the appearance of the optical display, negatively affecting the refraction of light into the film at the entry surface, and increasing the cost of assembling the optical display, so as to achieve the effect of improving the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following detailed description of the embodiments, reference is made to the accompanying drawings which form a part hereof, and in which are shown, by way of illustration, specific embodiments in which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the present invention.

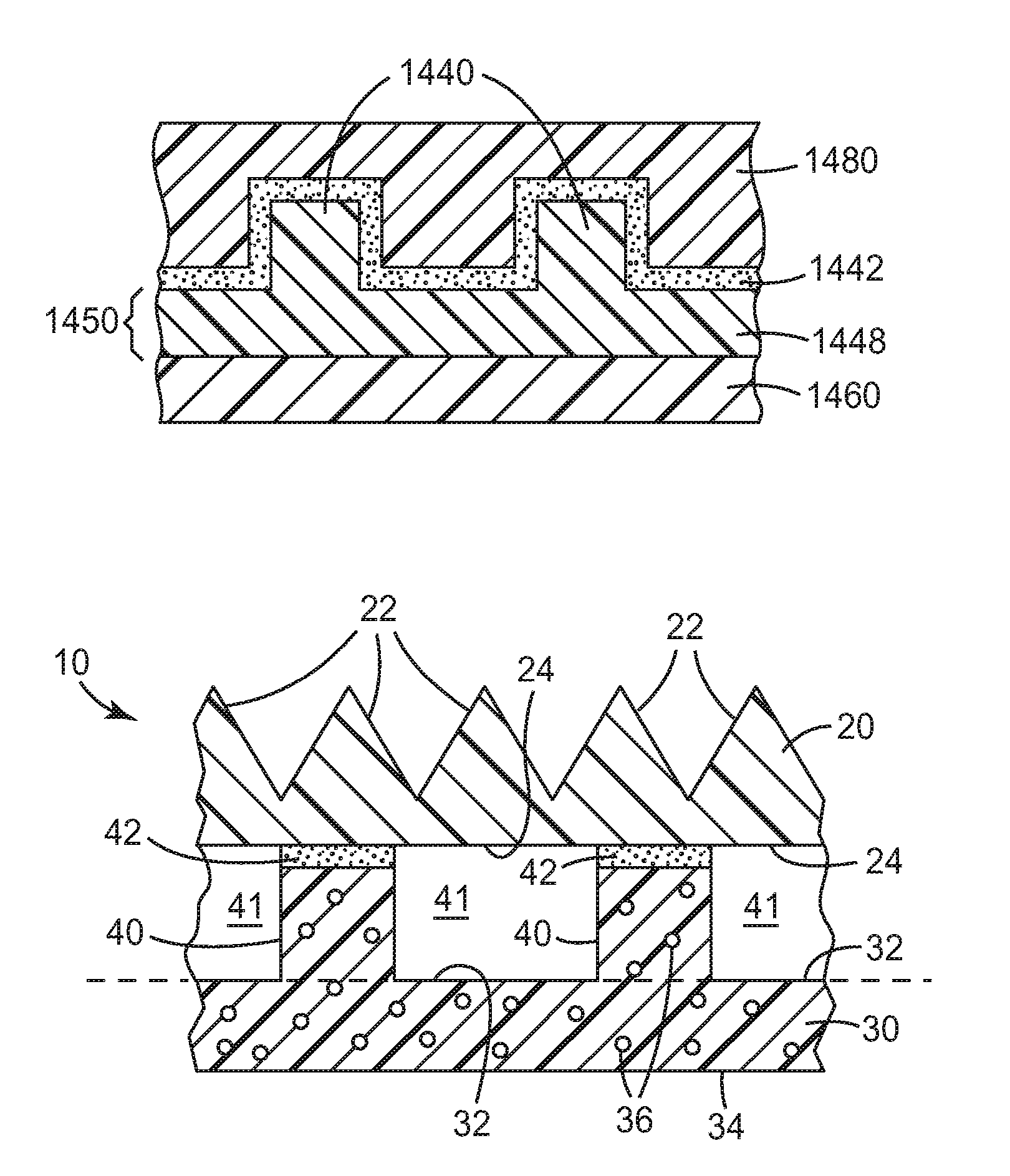

[0025] In some embodiments, the present invention as depicted in FIG. 1A provides an optical assembly 10′ that includes a light management component 20′ integrated with a light delivery component 30′. The attachment between the two components 20′ and 30′ is such that voids 41′ are created between them and between attachment points 40′ at which the light management component 20′ and the light delivery component 30′ are attached.

[0026] The voids 41′ are unfilled voids, i.e., they typically include one or more gases such as, e.g., air, nitrogen, etc. The unfilled voids 41′ preferably have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com