Model railroad switch actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following discussion is presented to enable a person skilled in the art to make and use the embodiments of the invention. Various modifications to the embodiments will be readily apparent to those skilled in the art, and the generic principles herein may be applied to other embodiments and applications without departing from the spirit and scope of the present invention as defined by the appended claims. Thus, the present invention is not intended to be limited to the embodiments show, but is to be accorded the widest scope consistent with the principles and features disclosed herein.

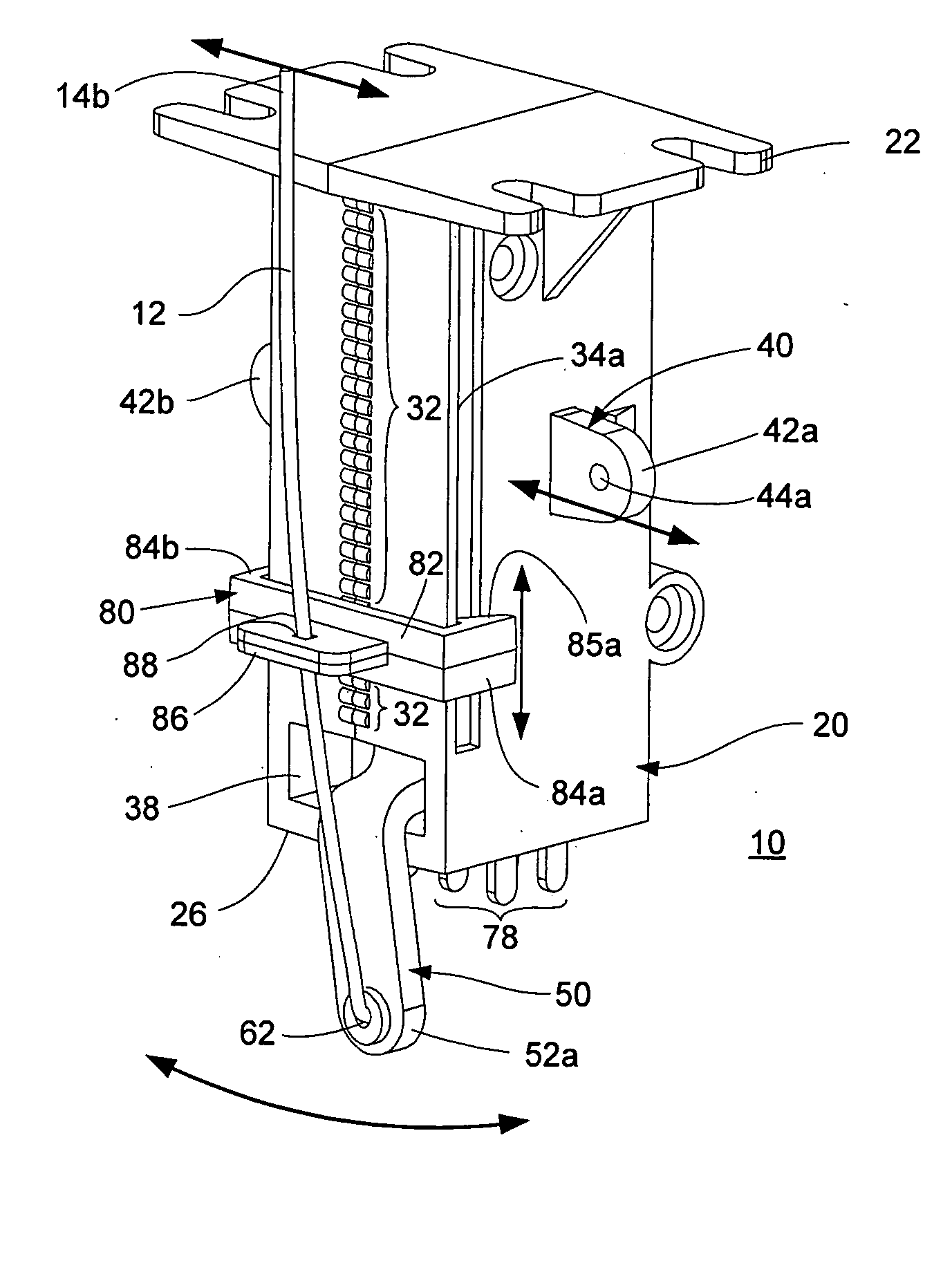

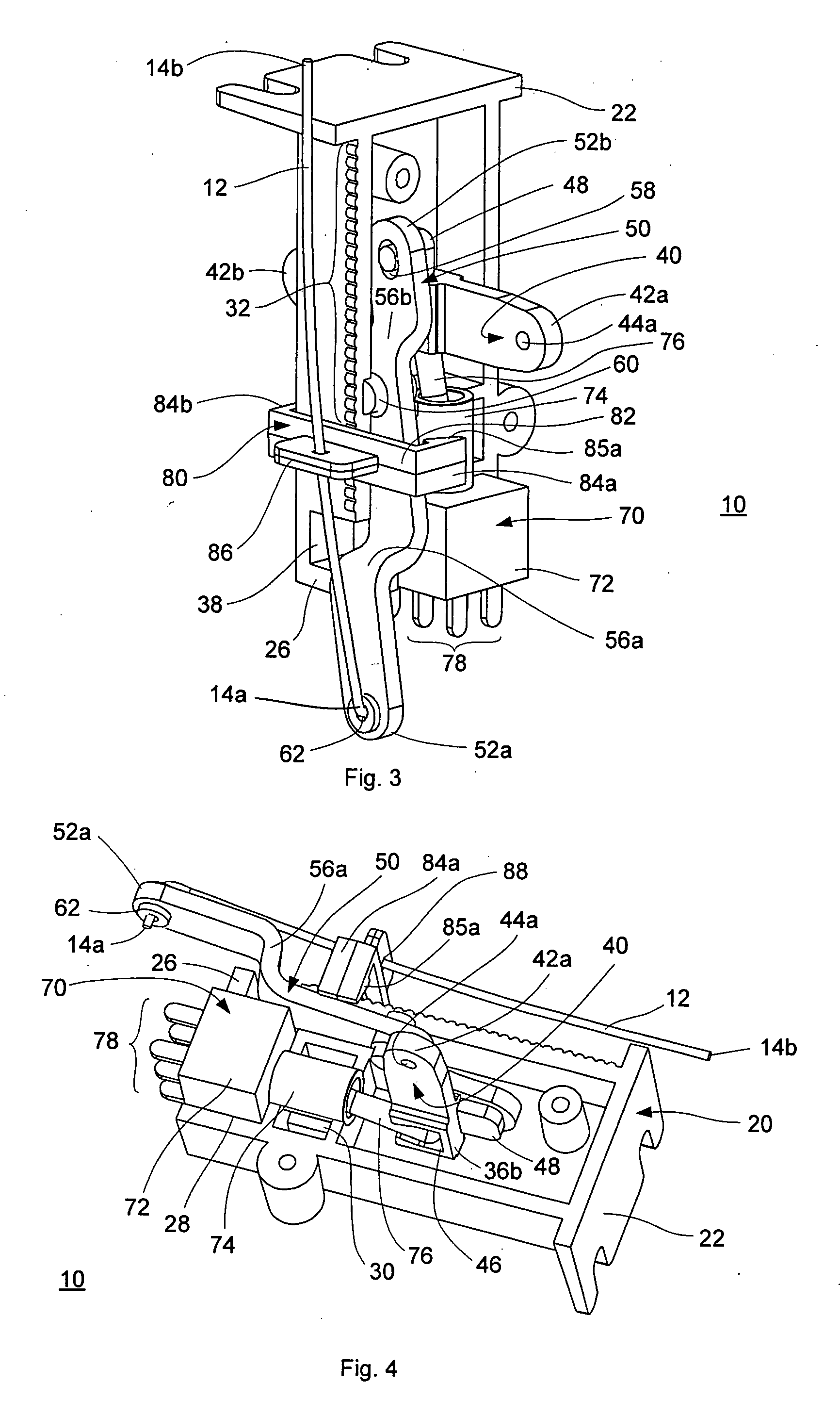

[0035] Turning then to the several Figures wherein like numerals indicate like parts and more particularly to FIGS. 1-4, a first switch actuator 10 is shown. Switch actuator 10 comprises housing 20 slider 40 lever 50 switch 70 and fulcrum 80. In particular, housing 20 includes mounting base 22 switch end 26, detents 32 fulcrum slots 34a and 34b, slider slots 36a and 36b, and lever arm slot 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com