Heat transfer tube and heat exchanger using same

a heat exchanger and heat transfer tube technology, applied in the direction of heat exhanger sealing arrangement, tubular elements, lighting and heating apparatus, etc., can solve the problems of complex and costly plural tube heat exchange step itself, high cost, and water and refrigerant mixing, and achieve the effect of enhancing the heat exchange performance of the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

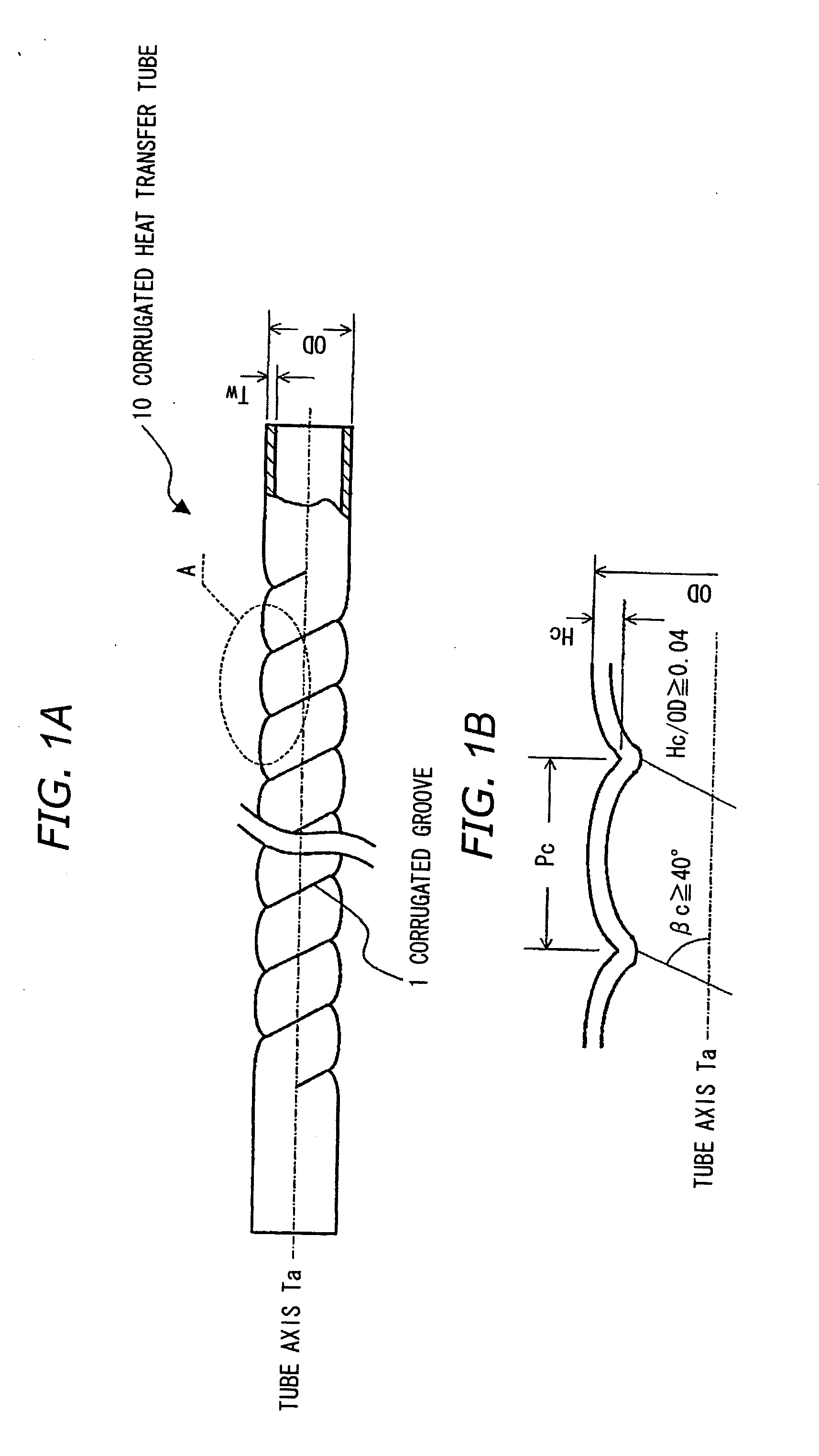

[0042]FIG. 1A is an explanatory diagram of an entire view showing structure of a heat transfer tube in a first preferred embodiment according to the present invention, and FIG. 1B is an enlarged cross-sectional view in region A of FIG. 1A.

[0043]A heat transfer tube (a corrugated heat transfer tube) 10 in this embodiment is formed of a one-thread corrugated tube (“one-thread” means that a number of a corrugated groove is one), and is used as a water tube that constitutes a heat exchanger (e.g., a water-refrigerant heat exchanger for a heat pump water heater), where a heat is exchanged between a water flowing inside the heat transfer tube 10 and a refrigerant flowing outside the heat transfer tube 10. The corrugated tube generally refers to a tube with an undulating helical structure in its inner / outer surface.

[0044]Let the corrugated groove depth and corrugation outside diameter of the corrugated heat transfer tube 10 in this embodiment be Hc and OD respectively, Hc / OD, which represe...

second embodiment

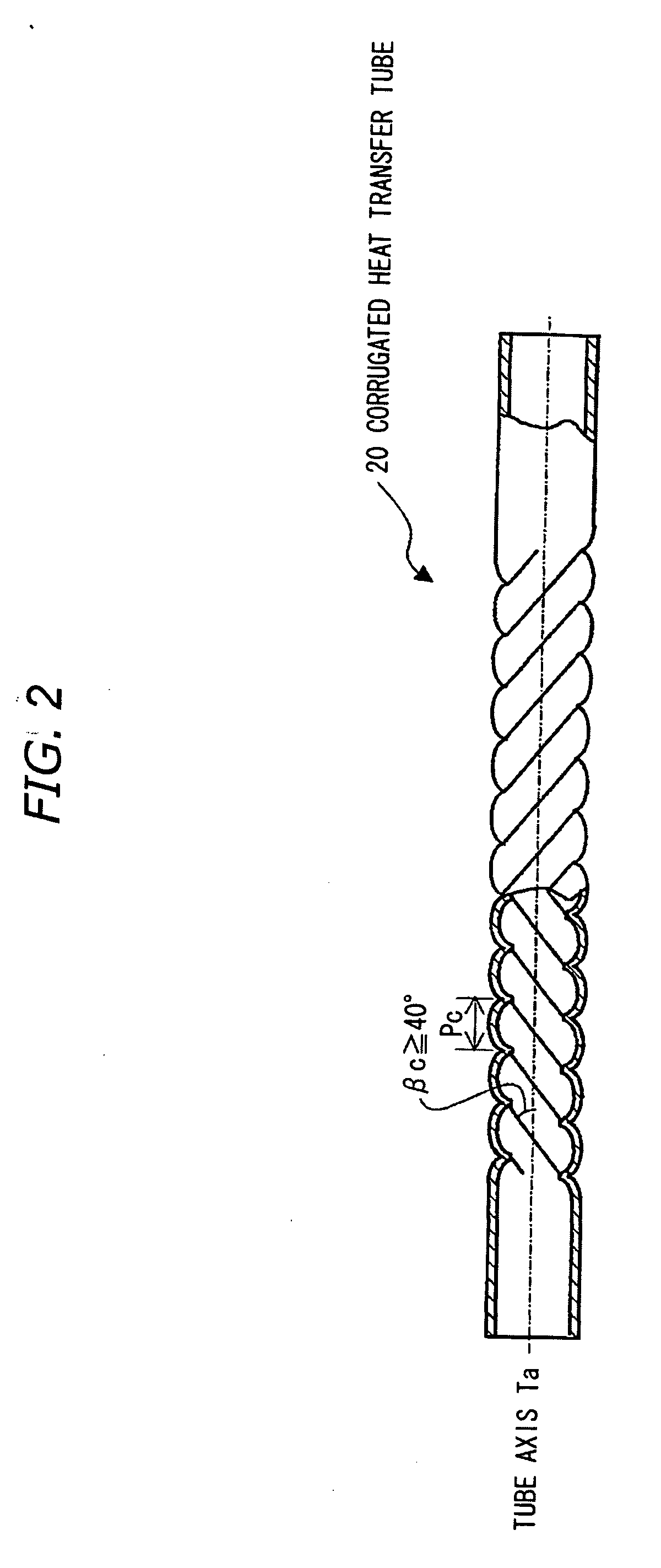

[0047]FIG. 2 is an explanatory diagram showing structure of a heat transfer tube in a second preferred embodiment according to the present invention.

[0048]While the heat transfer tube 10 in the first embodiment is formed from the one-thread corrugated tube, a heat transfer tube 20 in this second embodiment is formed from a three-thread corrugated tube (“three-thread” means that a number of a corrugated groove is three), and is used as a water tube that constitutes a heat exchanger. The more the number of threads, the higher the fabrication rate, which therefore results in a large cost merit.

[0049]Although the twist angle βc in three thread fabrication tends to be smaller than that of one thread fabrication, by reducing the spacing between the adjacent corrugated grooves 1, i.e., corrugation pitch Pc, a twist angle of 40° or higher, which is difficult to fabricate in the inner-grooved tube, can be realized.

[0050]Next, there is explained a heat exchanger equipped with the above corrug...

third embodiment

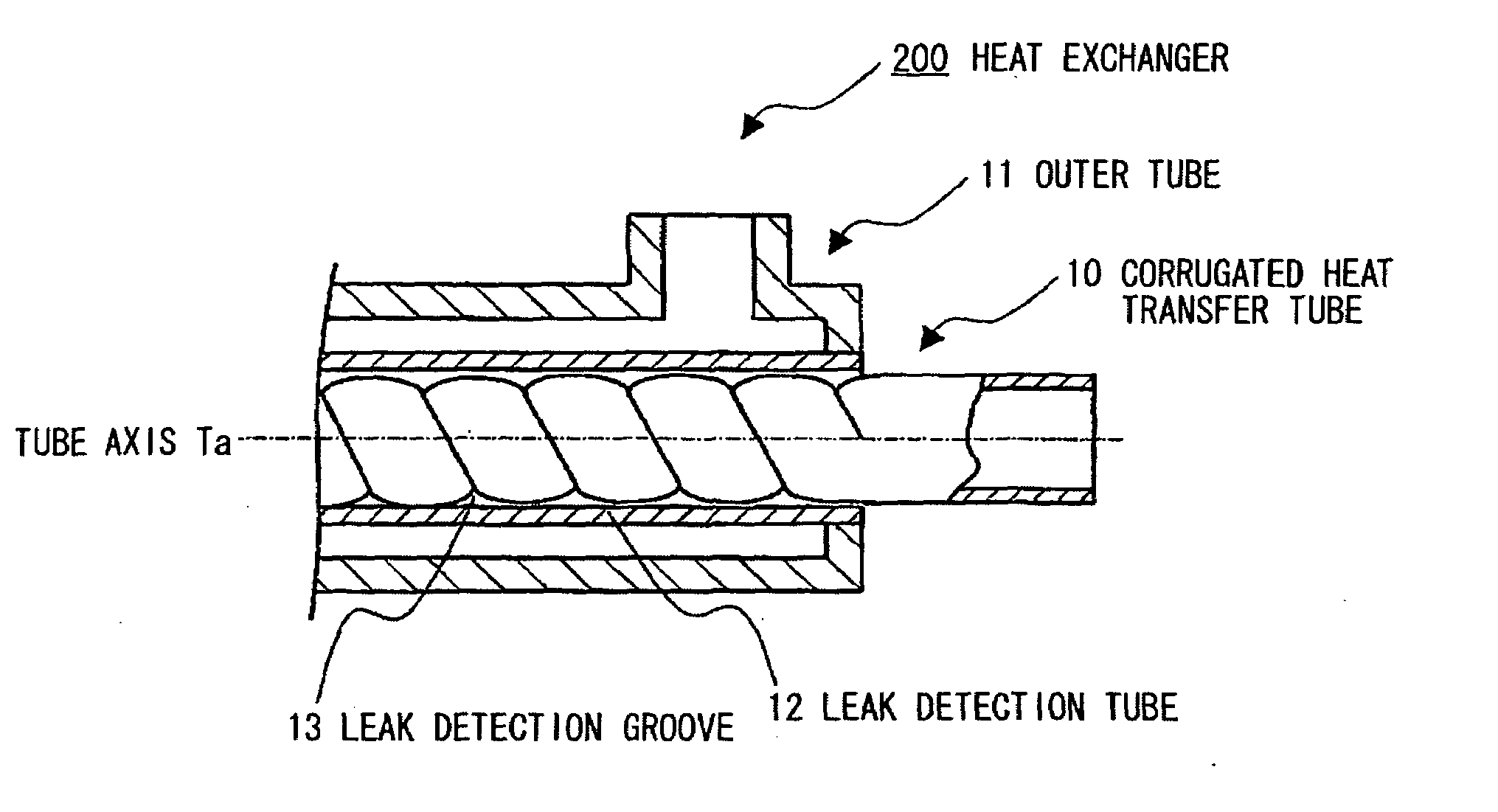

[0051]FIG. 3 is an explanatory diagram showing structure of a heat exchanger in a third preferred embodiment according to the present invention.

[0052]A heat exchanger (a double tube heat exchanger) 100 in this embodiment includes an outer tube 11 provided outside of the heat transfer tube (e.g., corrugated heat transfer tube 10) in the above-described embodiments that is used as an inner tube, where the heat exchanger is formed so that a refrigerant flows through an annular path between the corrugated heat transfer tube 10 and the outer tube 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com