Thin air processing device for heat ventilation air conditioning system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

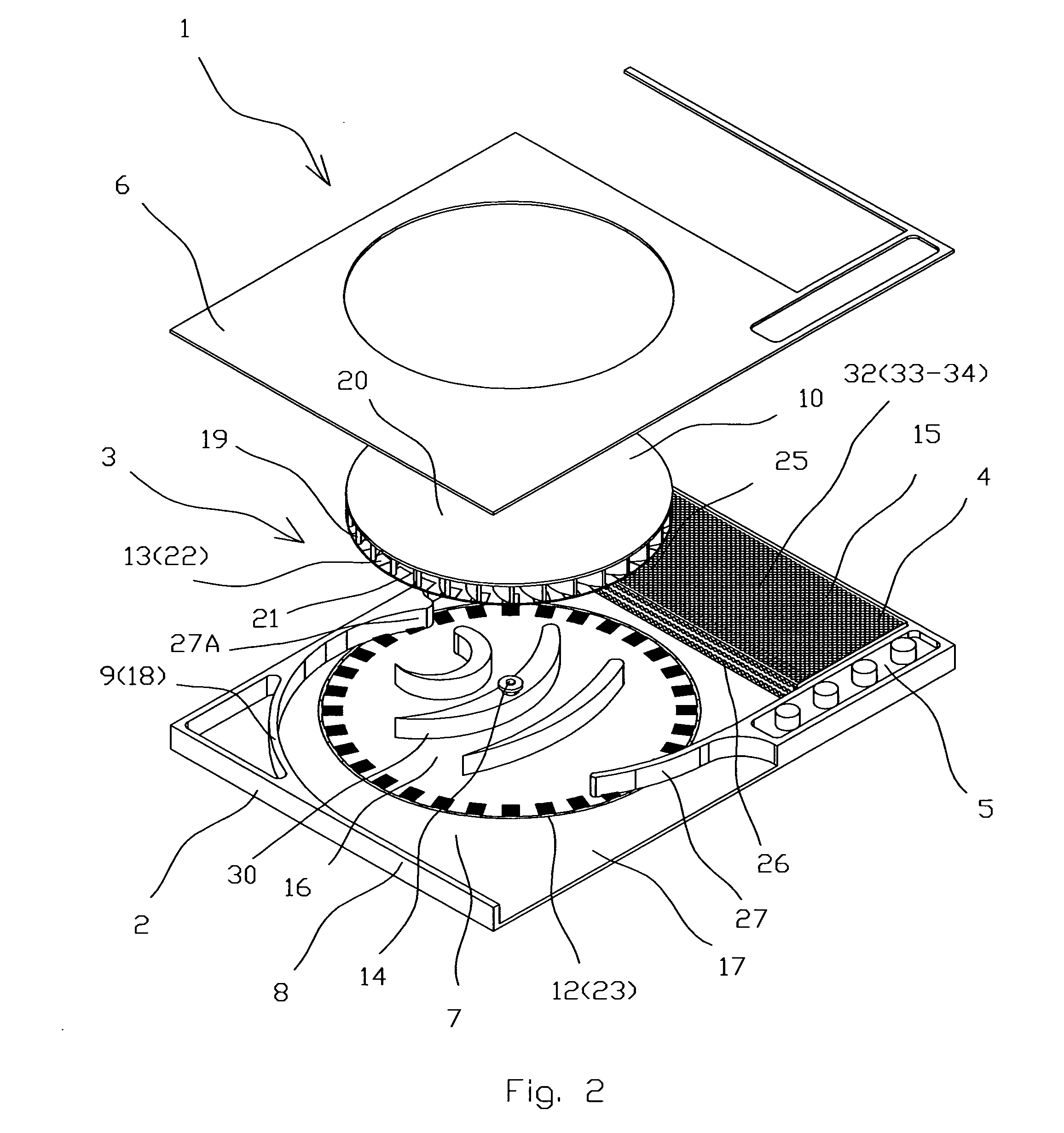

[0035]According to the present invention the flat stator 12 integrated with the cover plate 6 while the magnetic means 22 integrated with the backplate 20.

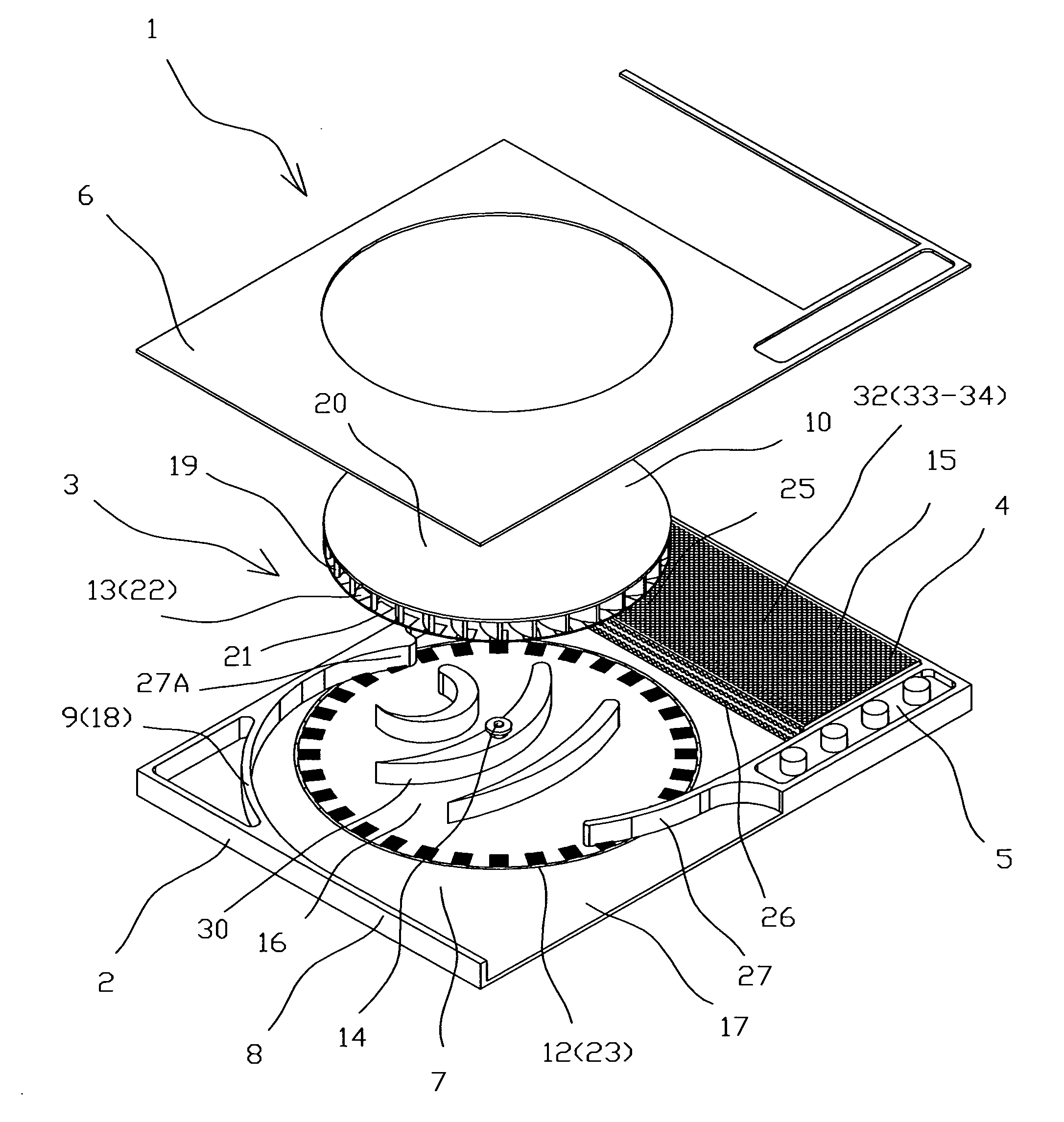

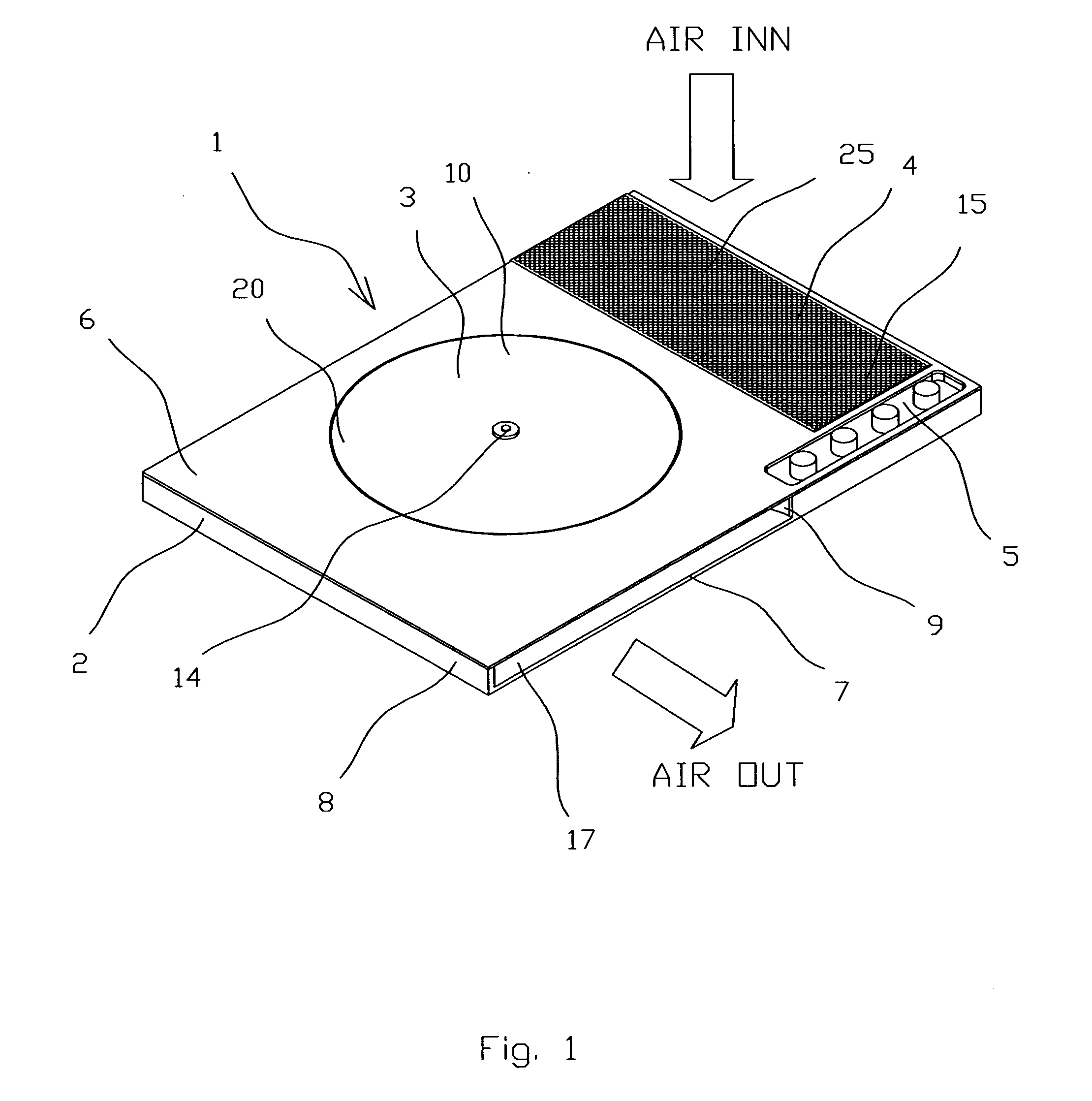

[0036]There are two design options according to both embodiments. The first design option (FIGS. 1-7) realizes an aerodynamic scheme when ambient air goes to the intake opening 25 of the air processing unit 4 in direction perpendicular to the cover plate 6, while the second design option (FIGS. 8-9) realizes the aerodynamic scheme when ambient air goes to the corresponding intake opening 25 from side in direction parallel to the cover plate 6.

third embodiment

[0037]According to the present invention (FIGS. 11-12A) at least one guide vane 30 integrated with the cover plate 7. Ambient air in this case goes to the intake opening 25 from side in direction parallel to the cover plate 6. Unlike the previous embodiments the backplate 20 located closer to the base 7 than shroud 21. The detailed mutual layout of components of the electric drive 11 is shown on FIGS. 12 and 12A. The coils 23 are integrated with the base 7 while magnetic means 22 are integrated with the backplate 20 by supporting ring 24 and retaining ring 35. The variant design shown on FIG. 12A differs from design shown on FIG. 12 by the conical upper surface 36 of the backplate 20 and may be used in extremely slim design of air processing device 1 according to the present invention.

[0038]According to all embodiments and variant designs the air processing unit 4 may be made like air purifier 32 and / or humidifier 34 and / or may comprises the temperature regulating means 33.

[0039]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com