Capacitive ultrasonic transducer, production method thereof, and capacitive ultrasonic probe

a capacitive ultrasonic transducer and ultrasonic probe technology, applied in electrostatic transducers, precision positioning equipment, chemical vapor deposition coatings, etc., can solve the problems of inconvenient production of capacitive ultrasonic transducers, inconvenient processing and assembly, and reduced center frequency, etc., to achieve efficient acoustic matching with tissue, low effective drive voltage, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

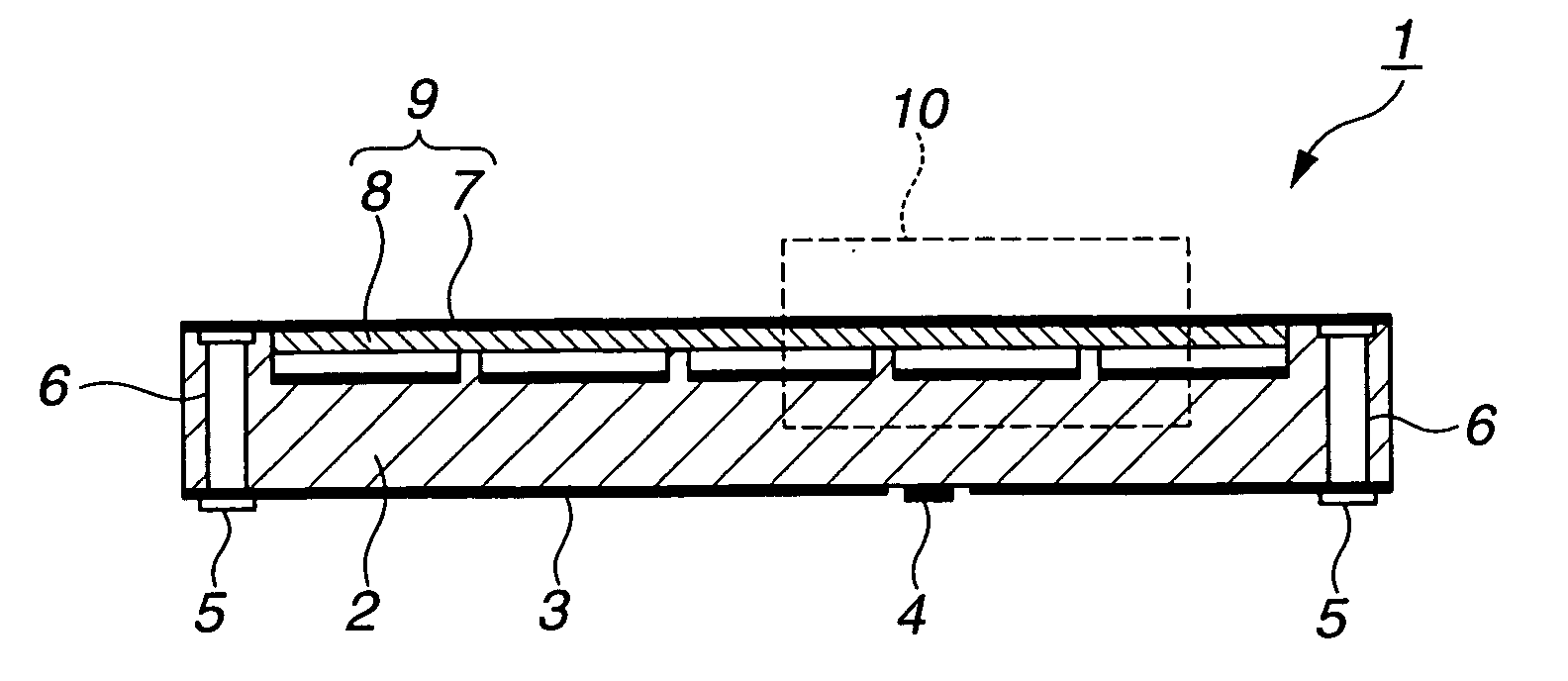

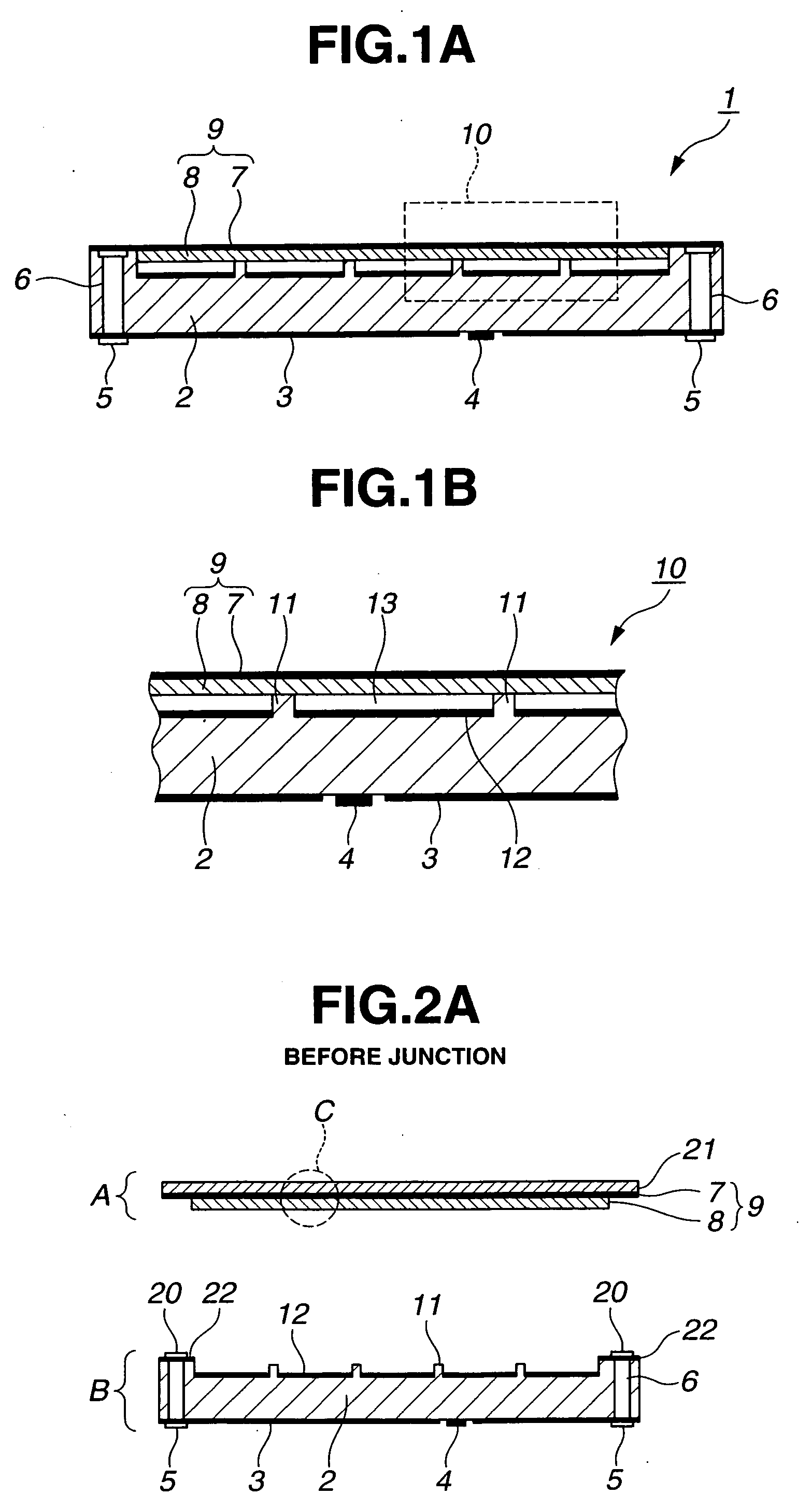

[0156]FIGS. 1A and 1B show basic structure of a capacitive ultrasonic transducer (c-MUT) 1 in this embodiment. FIG. 1A shows a sectional view of the whole capacitive ultrasonic transducer. A unit of the capacitive ultrasonic transducer shown in this FIG. 1A is called an element. In the capacitive ultrasonic transducer, there is a plurality of concavities on a surface of a silicon substrate 2. This one unit is called a cell 10. A membrane 9 covers an upper face of the silicon substrate 2 so as to cover each cell 10. The membrane 9 is a thin film (high dielectric constant film) which comprises an upper electrode 7 and a high dielectric constant oxide layer 8 mentioned later.

[0157] In addition, an insulating layer 3 is provided on a backface of the silicon substrate 2. A backface electrode pad (contact pad) 4 is provided in a part of this insulating layer 3. Interconnect via holes 6 are located in both ends of the silicon substrate 2. A contact pad 5 is provided on one end (a backface...

second embodiment

[0191] An example of a method of fabricating a capacitive ultrasonic transducer with a resin-made cavity forming substrate will be described as the present embodiment. Here, a cavity will hereinafter refer to space between an upper electrode and a lower electrode and does not necessarily have to be hollow. In addition, a concave portion or porosity, which is produced in a process (intermediate stage) prior to becoming a cavity at the time of final fabrication will be also referred to as a cavity.

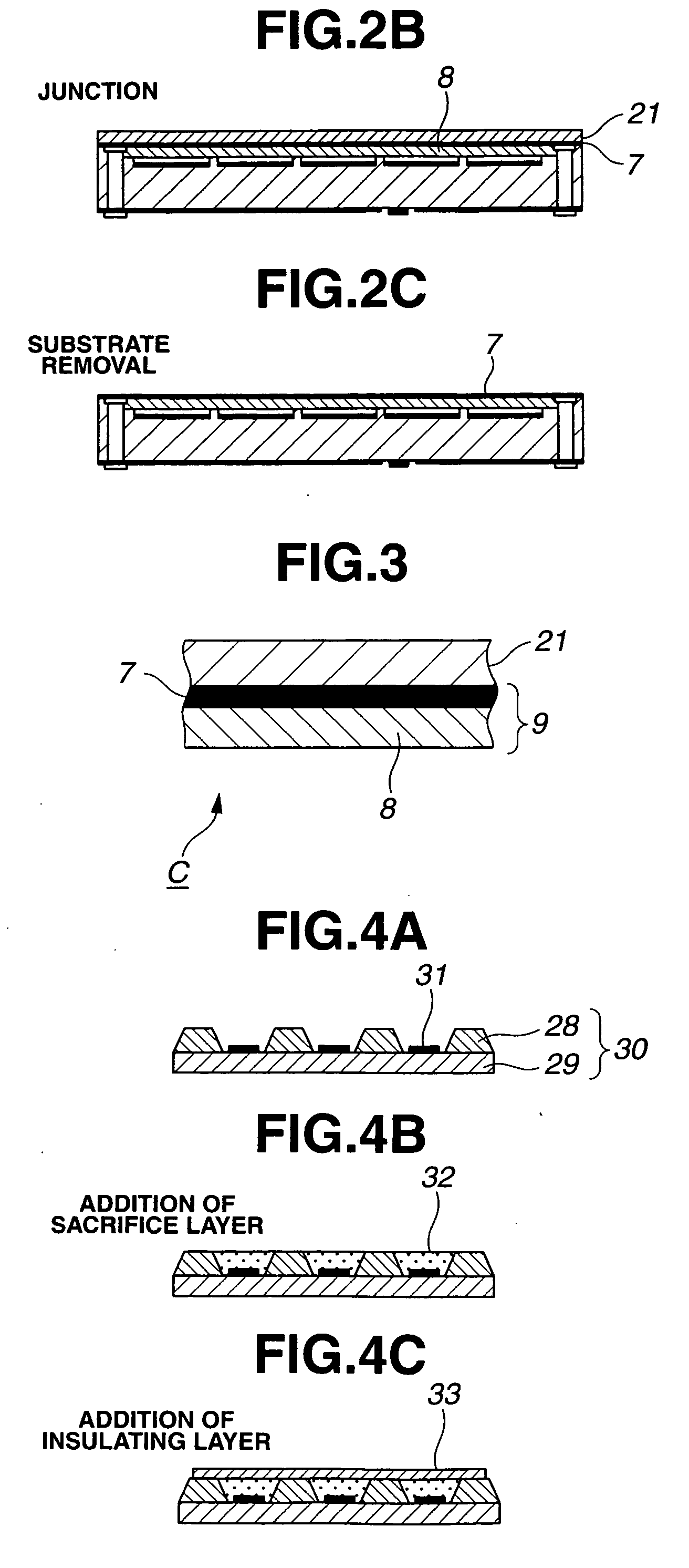

[0192]FIGS. 4A to 4E are drawings showing a fabrication process in the present embodiment. At first, an electrode 31 is formed on a surface of a silicon substrate. Next, on this silicon substrate 29, a supporting portion 28 is formed in a portion where no electrode 31 is disposed (a substrate comprising a silicon substrate 29, a supporting portion 28 and the electrode 31 will be referred to as a resin-made cavity forming substrate 30) (see FIG. 4A). Insulating material selected from the gro...

third embodiment

[0202] A method of fabricating a capacitive ultrasonic transducer with the anode bonding technology will be described in the present embodiment. The anode bonding technology refers to a technology of applying direct voltage of several hundreds of volts under several hundreds of ° C. and employing Si—O covalent bond to stick a silicon surface and a glass surface together. For the present embodiment, a cavity is formed with die forming in use of the technology hereof. Glass is glass including movable ions such as sodium ions and the like.

[0203]FIGS. 5A and 5B are drawings to show fabrication processing for the present embodiment. At first, a silicon substrate 42 subjected to patterning of a plate-like glass substrate 40 provided with a plurality of holes and electrodes 41 thereon is prepared (see FIG. 5A). As to be described below, the glass substrate 40 and the silicon substrate 42 are brought into bonding in the succeeding process and that electrode 41 undergoes patterning on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric constant | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com