Operating mode switch for setting at least one operating mode in a hand-held power tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

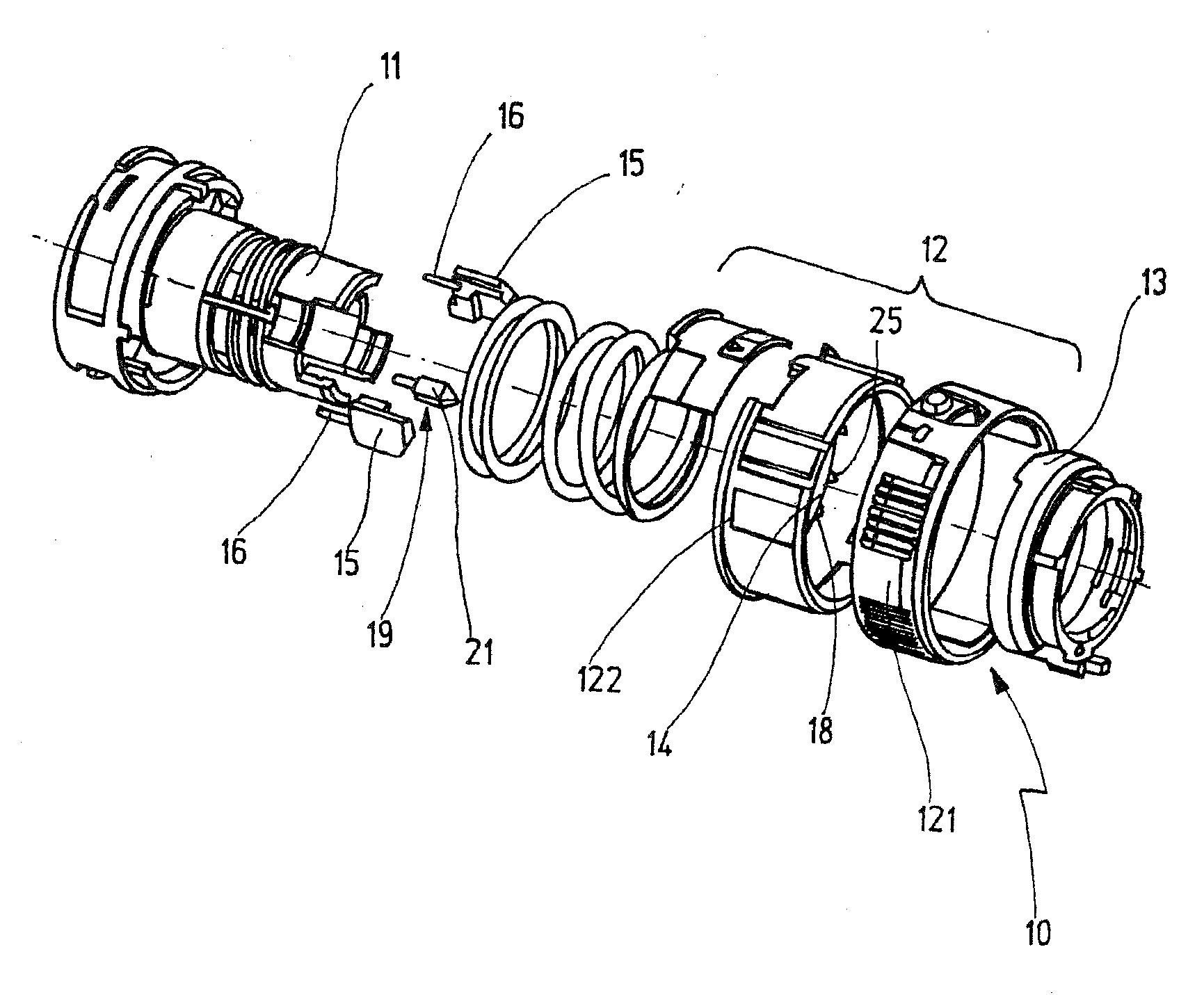

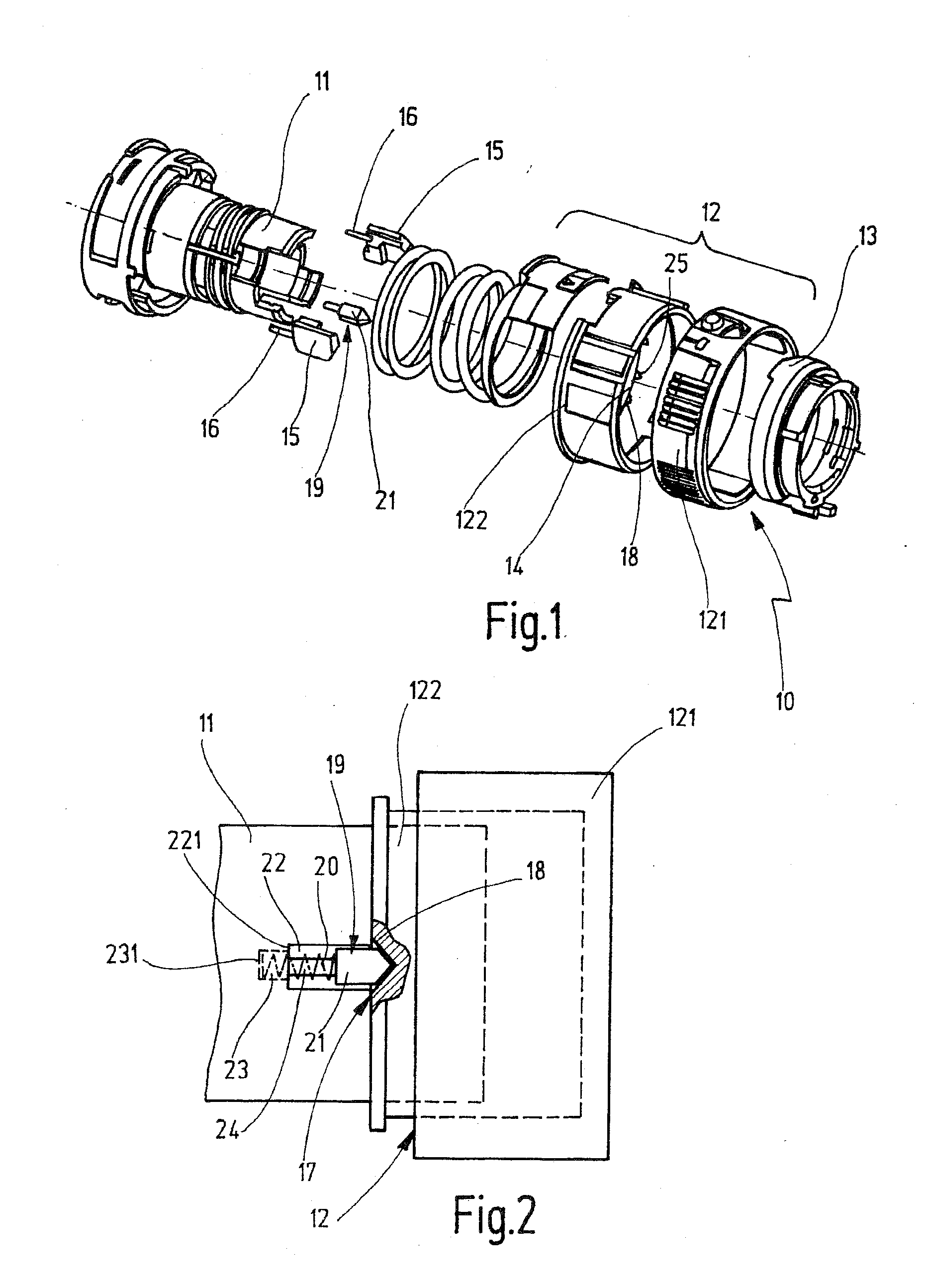

[0012] With the hand-held power tool shown in an exploded view, in sections, in FIG. 1, it is possible to switch to three different operating modes, i.e., the “impact drilling on / off” mode, the “drill” mode, and the “screw” mode, using an operating mode switch composed of two adjustment rings. In the “screw” mode, it is possible to preselect various starting torques. If this torque is exceeded, a safety clutch is activated, and the screwing tool cannot be driven.

[0013] The section of the hand-held power tool shown in FIG. 1 shows a guide sleeve 11 which is fixedly connected with the front region of a machine housing (not shown here) which accommodates an electric motor and a gearbox. A tool spindle (not shown here) is rotatably supported in guide sleeve 11, and operating mode switch 10 is located on guide sleeve 11. Operating mode switch 10 includes a setting ring for the “drill” and “screw” modes—and only one threaded ring 13 is shown—and a setting ring 12 with which the “impact d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com