Substrate buffer clamp

a buffer clamp and substrate technology, applied in the field of substrate bearing apparatus, can solve the problems of glass substrate or the panel not being usable or reworked, and the difficulty of the related manufacturing technology becoming higher, and achieve the effect of reducing the problem of glass substrate splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

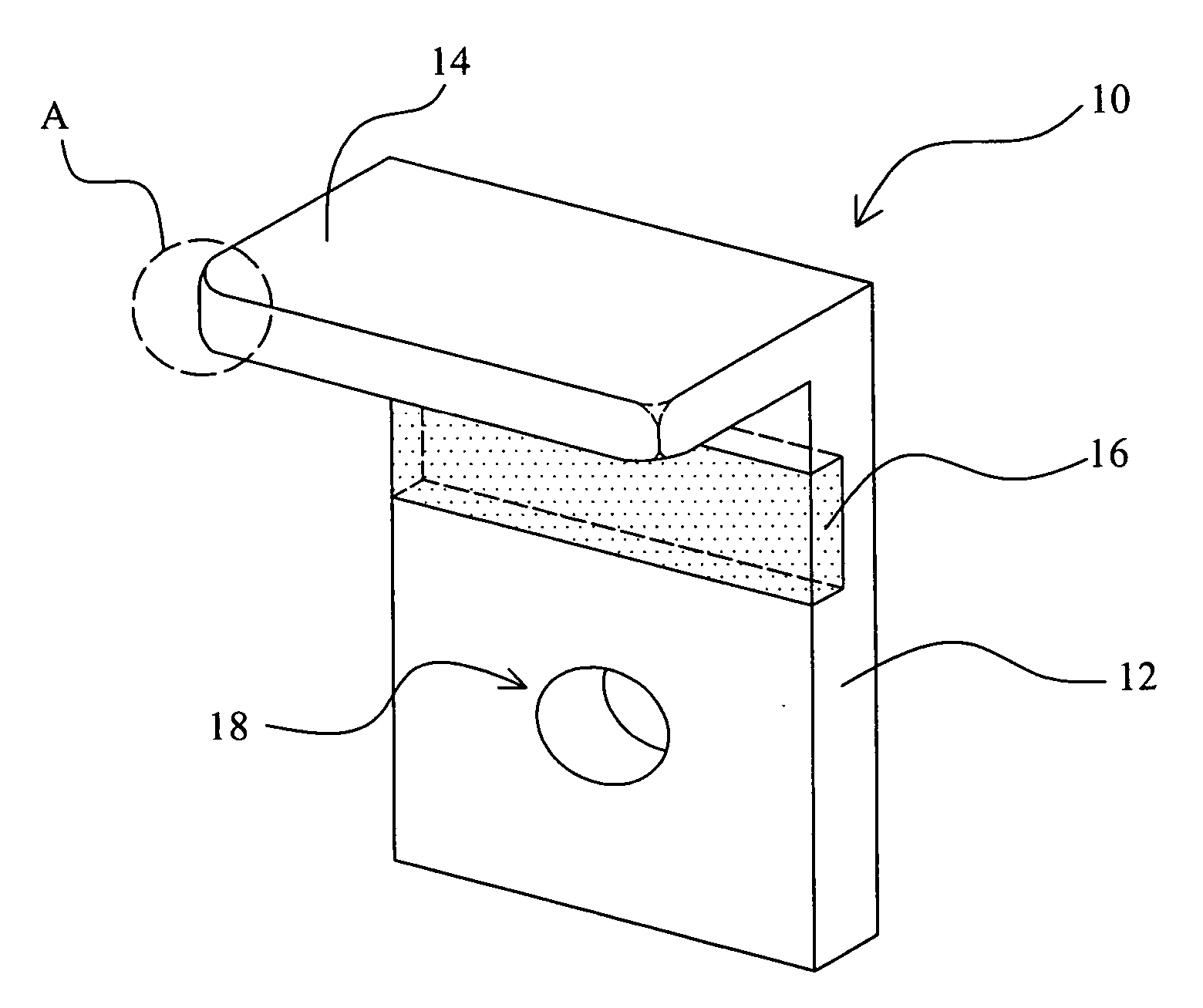

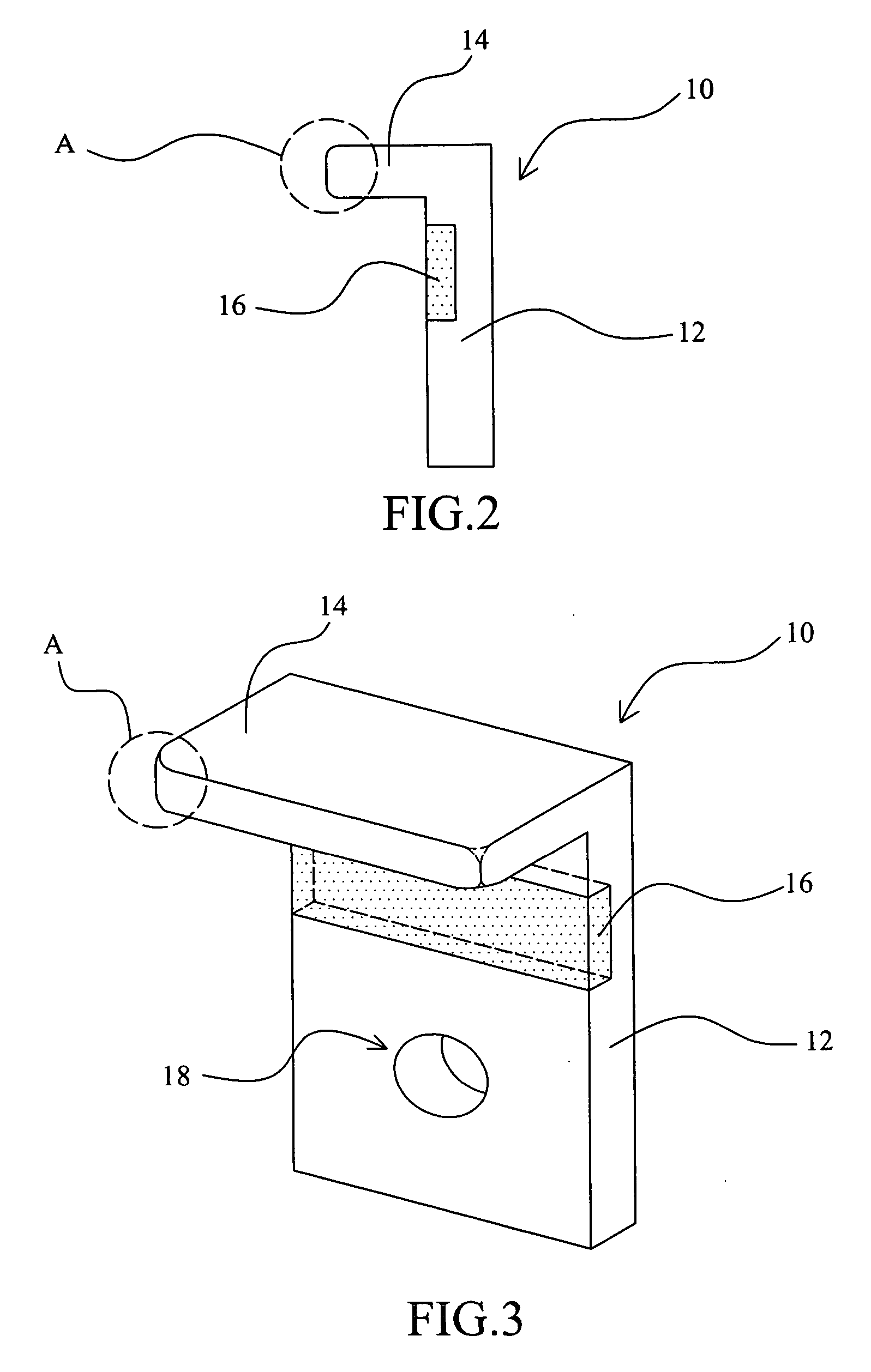

[0017] Referring to FIG. 2, it is the side view illustrating the substrate clamp of an embodiment in accordance with the present invention. In the present embodiment, a substrate clamp 10 includes a bar supporter 12, wherein one end of the bar supporter 12 is connected and fixed to the substrate bearing apparatus. An arm 14 is extended from another end of the bar supporter 12 and an angle between the sidewall of the bar supporter 12 and the arm 14. Besides, there is a buffer layer 16 arranged on the sidewall of the bar supporter 12. The buffer layer 16 has a hardness smaller than the bar supporter 12 and used for reducing the colliding force between the glass substrate and the substrate clamp and the loosening problem. Further, in the present embodiment, there is a right angle profiling between the arm 14 and the sidewall of the bar supporter 12. Such as the region A shown in FIG. 2, the terminal of the arm 14 is a chamfered edge. In the present invention, the arm 14 extending as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com