Seal device and method for operating the same and substrate processing apparatus comprising a vacuum chamber

a technology of sealing device and vacuum chamber, which is applied in the direction of engine sealing, thin material processing, basic electric elements, etc., can solve the problems of foreign matter contained in the second space b, 2/b> and may become mixed in the gas flow, so as to avoid the risk of contamination of a space, reduce the time required for reproducing a vacuum, and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

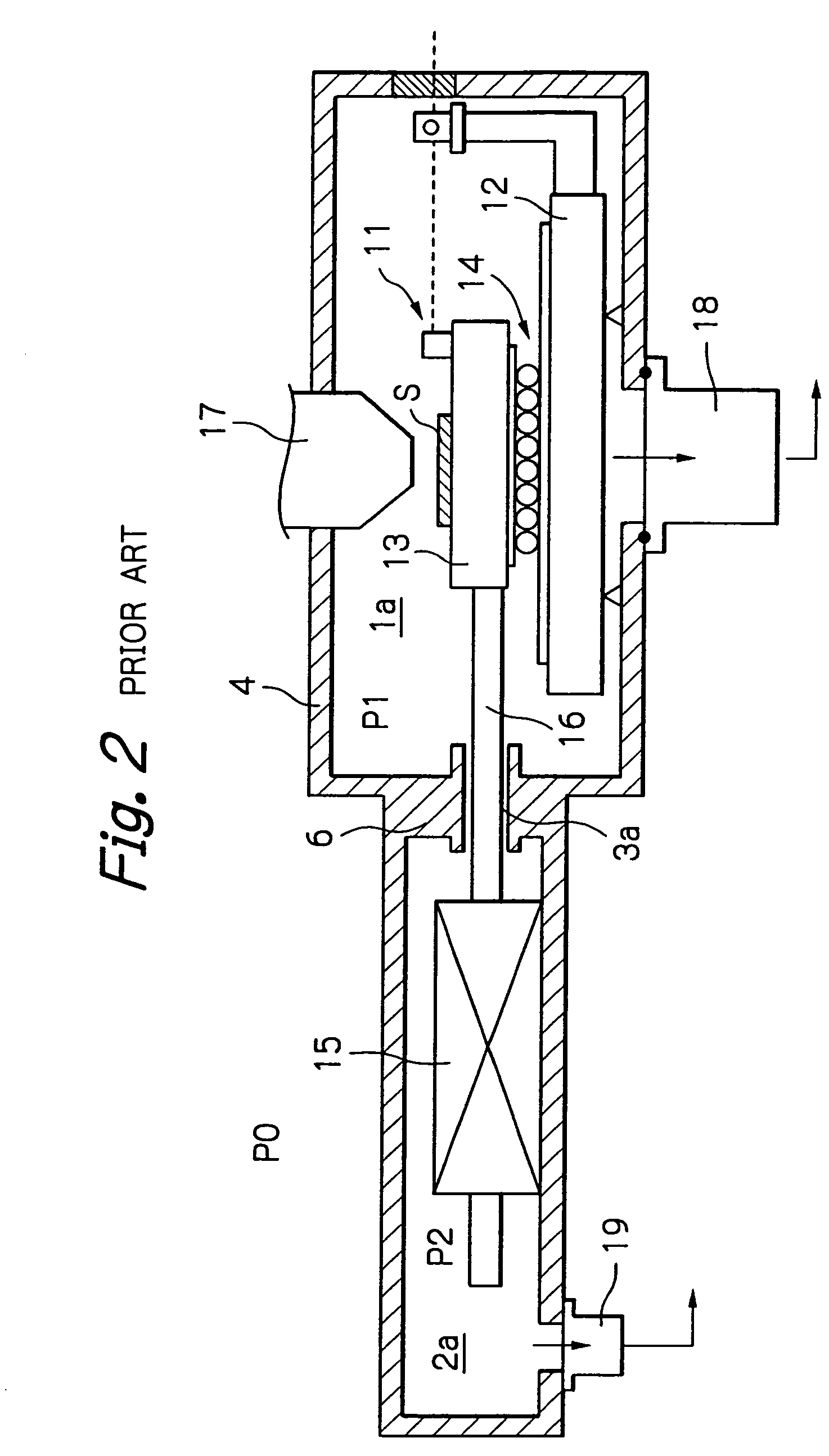

[0097] Hereinbelow, embodiments of the present invention are explained, with reference to FIGS. 10 to 15. As has been described, the problems arising at the time of starting the seal device are such that: (1) a gas occupying the second space 2, which has a lower degree of cleanliness than the first space 1, flows into the first space 1, resulting in a lowering of cleanliness of the first space 1; (2) due to a high humidity of the gas flowing from the second space 2, water is deposited on an inner surface of a wall defining the first space 1, thus lowering the ultimate degree of vacuum in the first space 1; and (3) foreign matter enters a narrow gap in the sealing passage 3, and clogs the sealing passage 3.

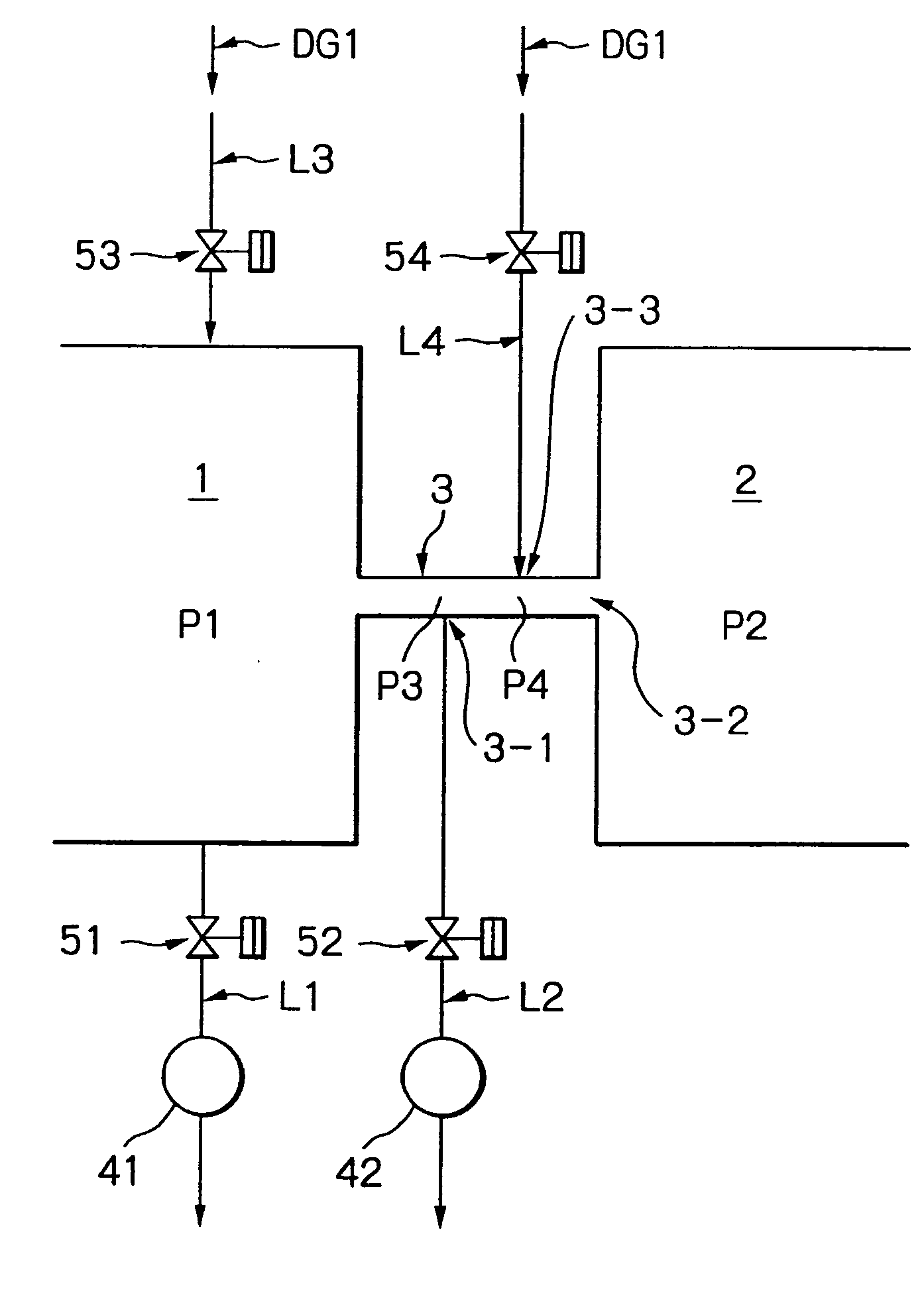

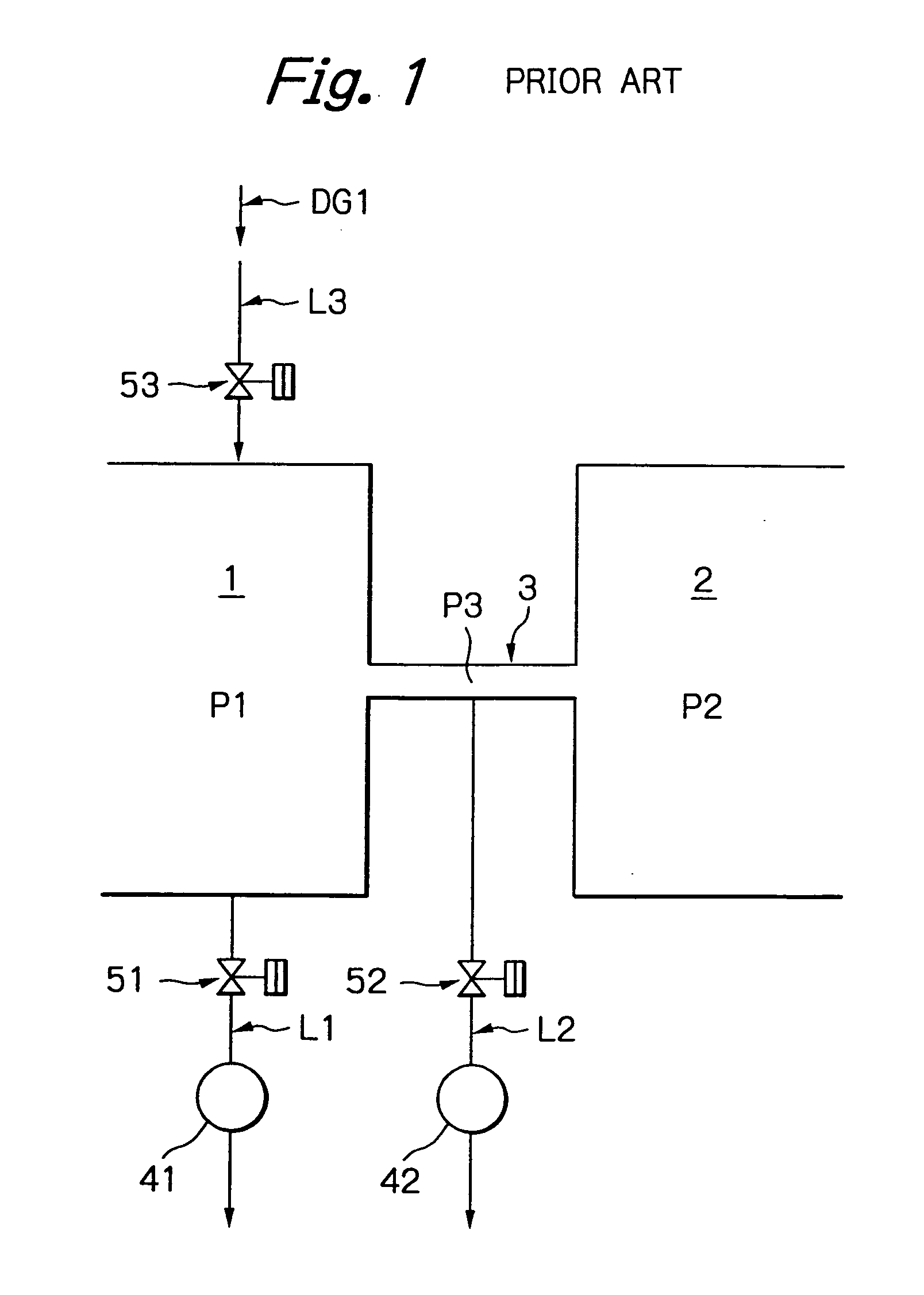

[0098]FIG. 10 is a diagram showing a principle of a seal device of the present invention. This seal device is the same as the seal device shown in FIG. 1, in that the sealing passage 3 is provided between the first space 1 and the second space 2, the evacuation line L1 provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com