Tank opening-closing device

a technology of opening and closing a fuel passage and a valve body, which is applied in the direction of liquid handling, packaging goods, transportation and packaging, etc., can solve the problems of complex linking structure, poor operability of fuel caps, and difficulty in satisfying both simultaneously, so as to improve operability and simplify the structure. , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] (1) Schematic Structure of the Tank Opening-Closing Mechanism

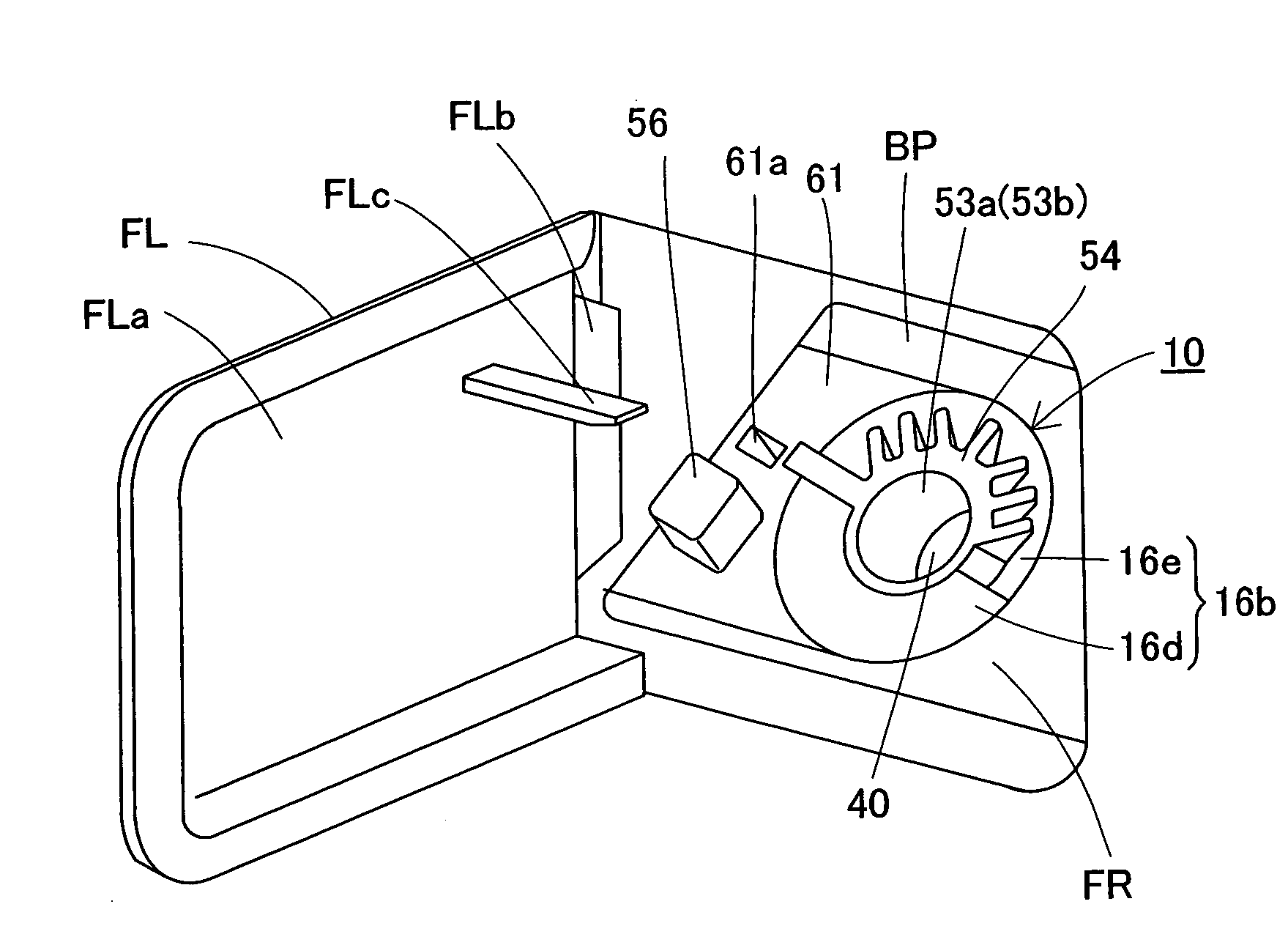

[0030]FIG. 1 is a perspective view illustrating the opened state of a fueling lid that is disposed in the rear portion of an automobile in accordance with an embodiment of the present invention. A fueling lid FL for supplying fuel is supported at the rear portion of the body of an automobile so as to be able to open and close. In the fueling lid FL, a lid main body FLa is supported at an exterior panel of the automobile so as to be able to open and close at the exterior panel of the automobile by a hinge FLb. The space wherein the fueling lid FL opens forms a fueling room FR, where a tank opening-closing device 10 is supported on a base plate BP within the fueling room FR. The tank opening-closing device 10 is a mechanism for supplying fuel to a fuel tank without the use of a fuel cap, and is structured so as to enable the supply of fuel to the fuel tank from a fueling gun through opening the fuel passage by, for e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com