Assembly for controlling thermal stresses in ceramic matrix composite articles

a technology of ceramic matrix and composite articles, which is applied in the direction of mechanical equipment, machines/engines, lighting and heating apparatus, etc., can solve the problems of increasing the durability of high temperature engine components, and the proneness of cmc vanes to thermally-induced stresses and strains, etc., to achieve the effect of increasing the rigidity of the first body, promoting heat transfer, and ensuring the durability of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

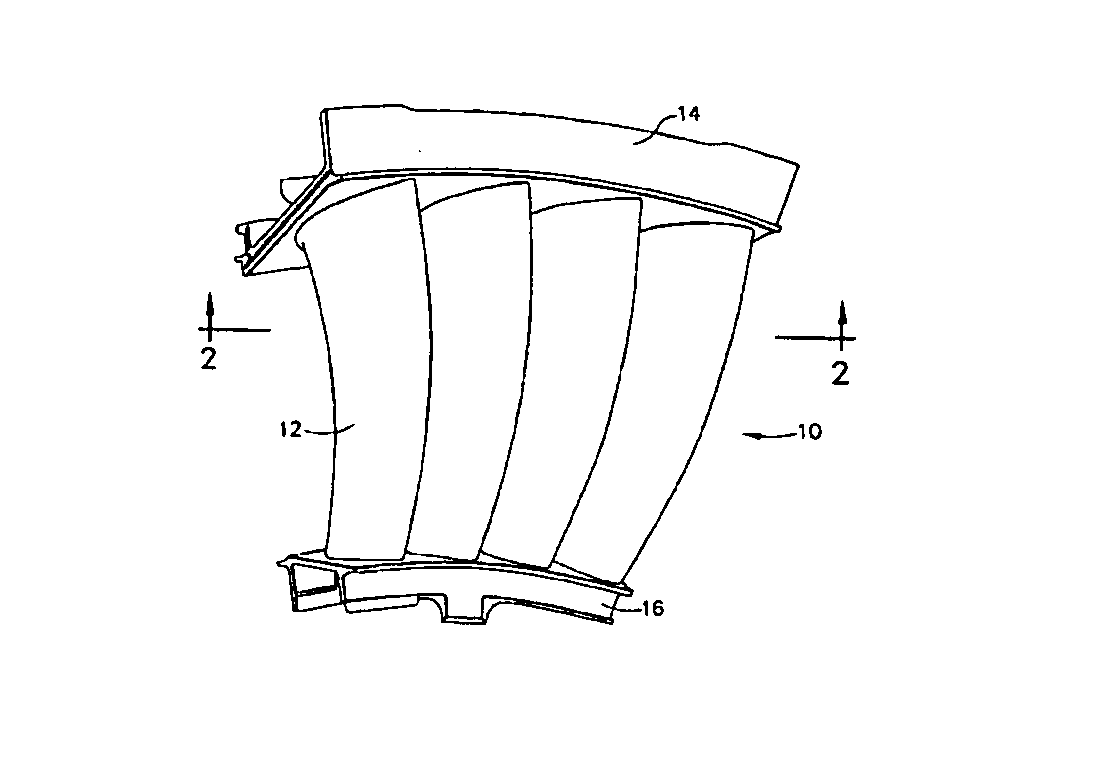

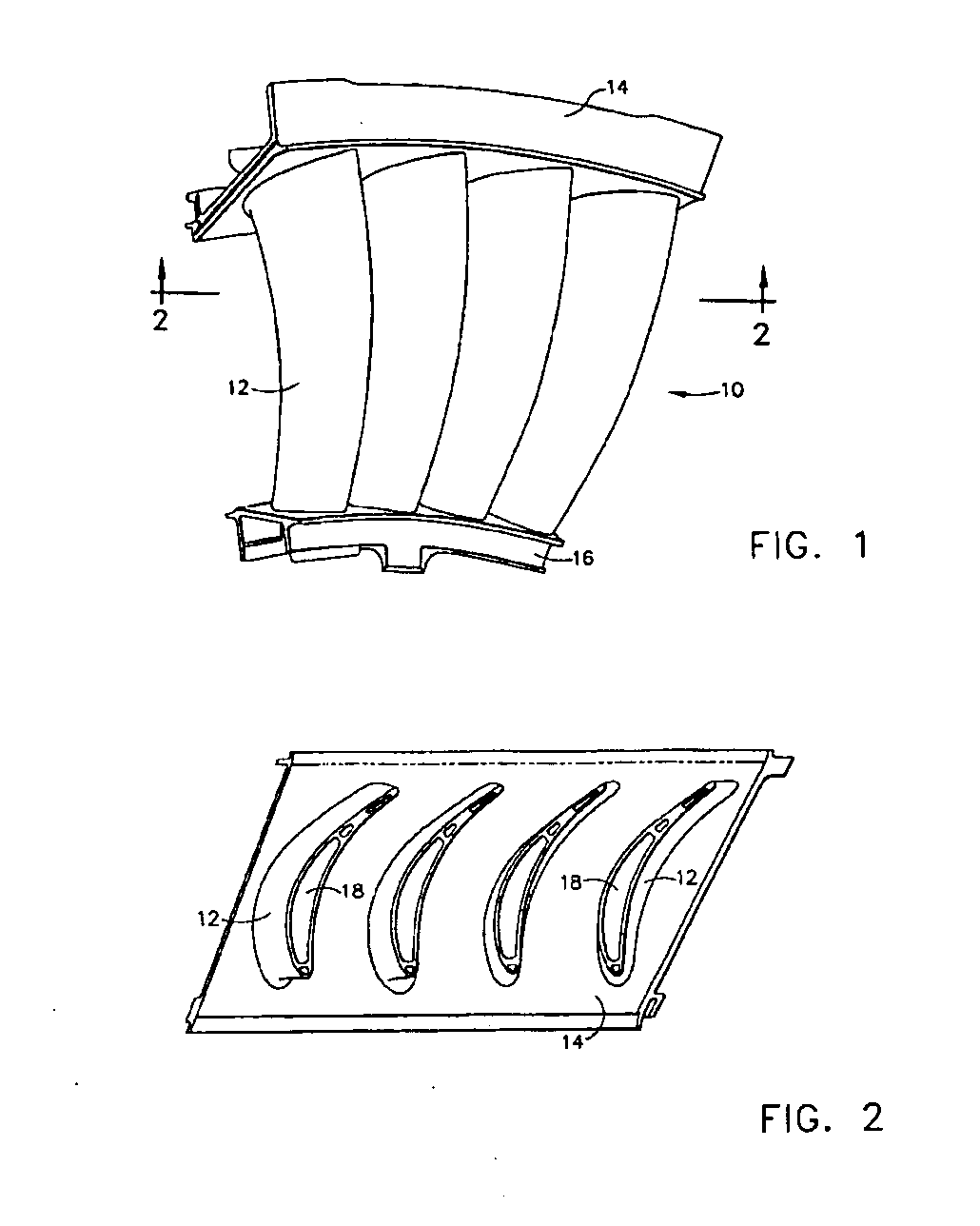

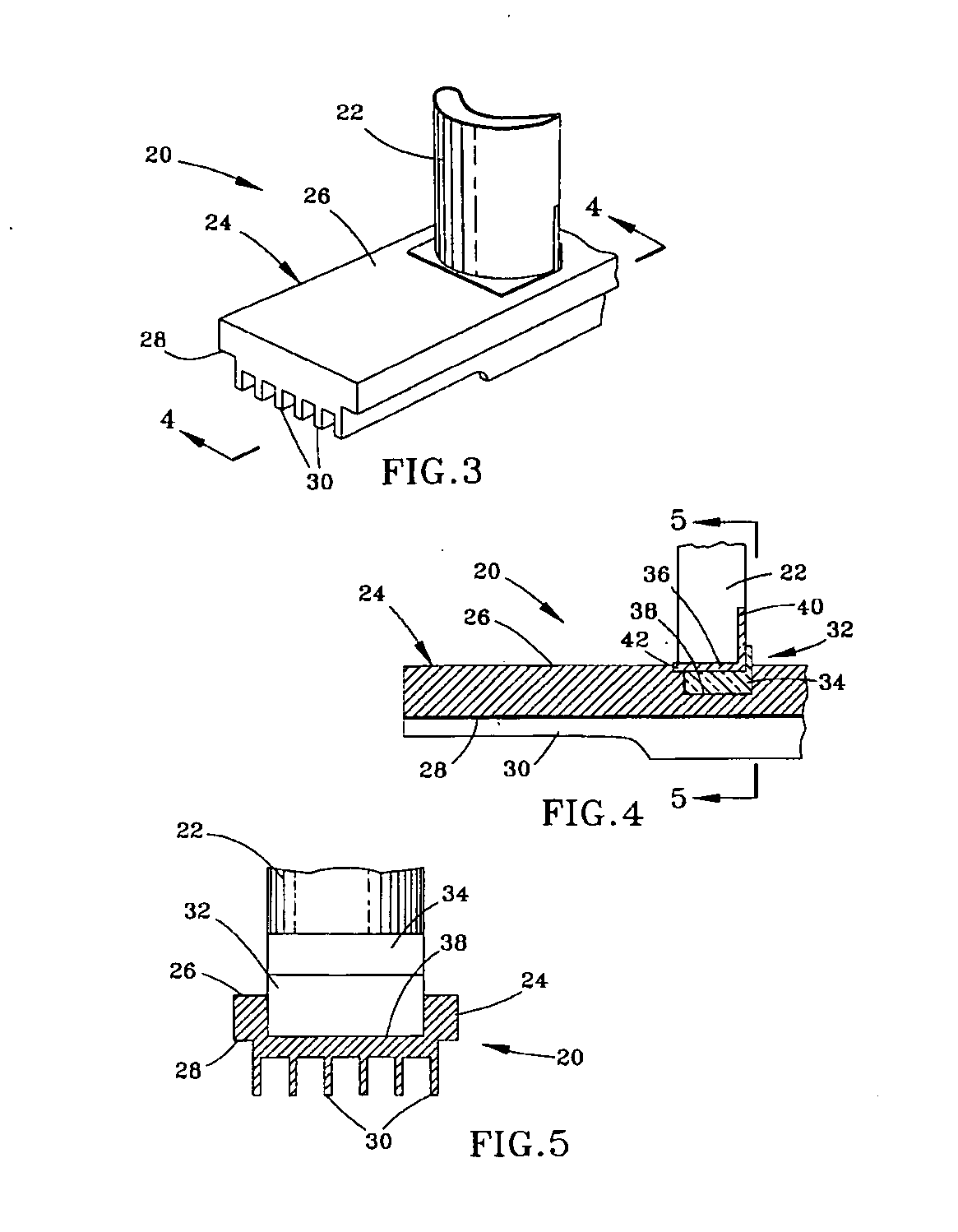

[0017]FIGS. 3 through 5 schematically represent a portion of a nozzle segment 20 that, when assembled with similarly configured segments, forms an annular-shaped HPT nozzle assembly of a gas turbine engine. The nozzle segment 20 is depicted as including a single vane 22 supported by a single platform 24, though it will be understood that multiple vanes can be supported by the platform 24 in combination with a second platform, resulting in a construction generally similar to that shown in FIGS. 1 and 2. The vane 22 is depicted as being hollow, though a variety of configurations are possible, including vanes configured to have struts, spars, inserts for mechanical support, baffles for enhanced internal cooling, etc. While the invention will be described in reference to a HPT nozzle assembly, it will be appreciated that the benefits of the invention can be applied to a variety of other components, including but not limited to low pressure turbine (LPT) nozzle assemblies and other hot s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com