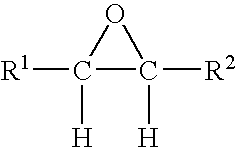

Catalysts having enhanced stability, efficiency and/or activity for alkylene oxide production

a technology of alkylene oxide and catalyst, which is applied in the direction of physical/chemical process catalyst, metal/metal-oxide/metal-hydroxide catalyst, bulk chemical production, etc., can solve the problems of catalyst replacement or regeneration, loss of production time, time, productivity and materials, and unacceptable low efficiency and/or activity of catalyst, etc., to achieve the effect of improving the activity, efficiency and/or stability of the resultant catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Catalyst 1 and Comparative Catalyst 2

[0087] Eighty cubic centimeters of each catalyst (61.4 g.) was charged to an autoclave reactor and tested under Air Process Conditions—I (Table I). Outlet ethylene oxide was set to 1.2 mole percent until day 6 when it was increased to 1.4 mole percent. Table IV compares the performance of the catalyst containing 2 weight percent zircon (Catalyst 1) with one containing no zircon (Comparative Catalyst 2). The catalyst containing zircon has higher initial efficiency and lower initial temperature (higher activity).

TABLE IVExample 1 Catalyst PerformanceEfficiency %Temp. ° C.2 Mlb5 Mlb7 Mlb2 Mlb5 Mlb7 MlbEO / CFEO / CFEO / CFEO / CFEO / CFEO / CFCatalyst 176.474.771.7260269280Catalyst 274.873.471.6266274281(comparative)

example 2

Catalyst 3 and Comparative Catalyst 4

[0088] An equal weight (63.5 g.) of each catalyst was charged to an autoclave reactor and tested under the Air Process Conditions—I described in Table I. The outlet ethylene oxide was set to 1.4 mole percent and temperature and efficiency monitored as the catalysts aged. Table V compares performance of the two catalysts as a function of pounds of EO produced per cubic foot of catalyst. Although the initial efficiency is lower than the comparative catalyst, over time, the zircon-containing catalyst ages in efficiency and temperature at a slower rate.

TABLE VExample 2 Catalyst PerformanceEfficiency %Temp. ° C.8 Mlb20 Mlb35 Mlb8 Mlb20 Mlb35 MlbEO / CFEO / CFEO / CFEO / CFEO / CFEO / CFCatalyst 378.277.777.2249253256Catalyst 479.978.475.9243251259(comparative)

example 3

Catalyst 5 and Comparative Catalyst 6

[0089] An equal weight (63.5 g.) of each catalyst was tested in an autoclave under Oxygen Process Conditions—I (Table I). Outlet ethylene oxide concentration was set to 1.0 mole percent. Catalyst 5 has higher efficiency and lower temperature compared to Comparative Catalyst 6, which does not contain zircon.

TABLE VIExample 3 Catalyst PerformanceEfficiency (%)Temp. (° C.)1 Mlb2.5 Mlb1 Mlb2.5 MlbEO / CFEO / CFEO / CFEO / CFCatalyst 580.480.0232230Catalyst 676.677.7253253(comparative)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com