Sealed container lid of vacuum valve operation type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

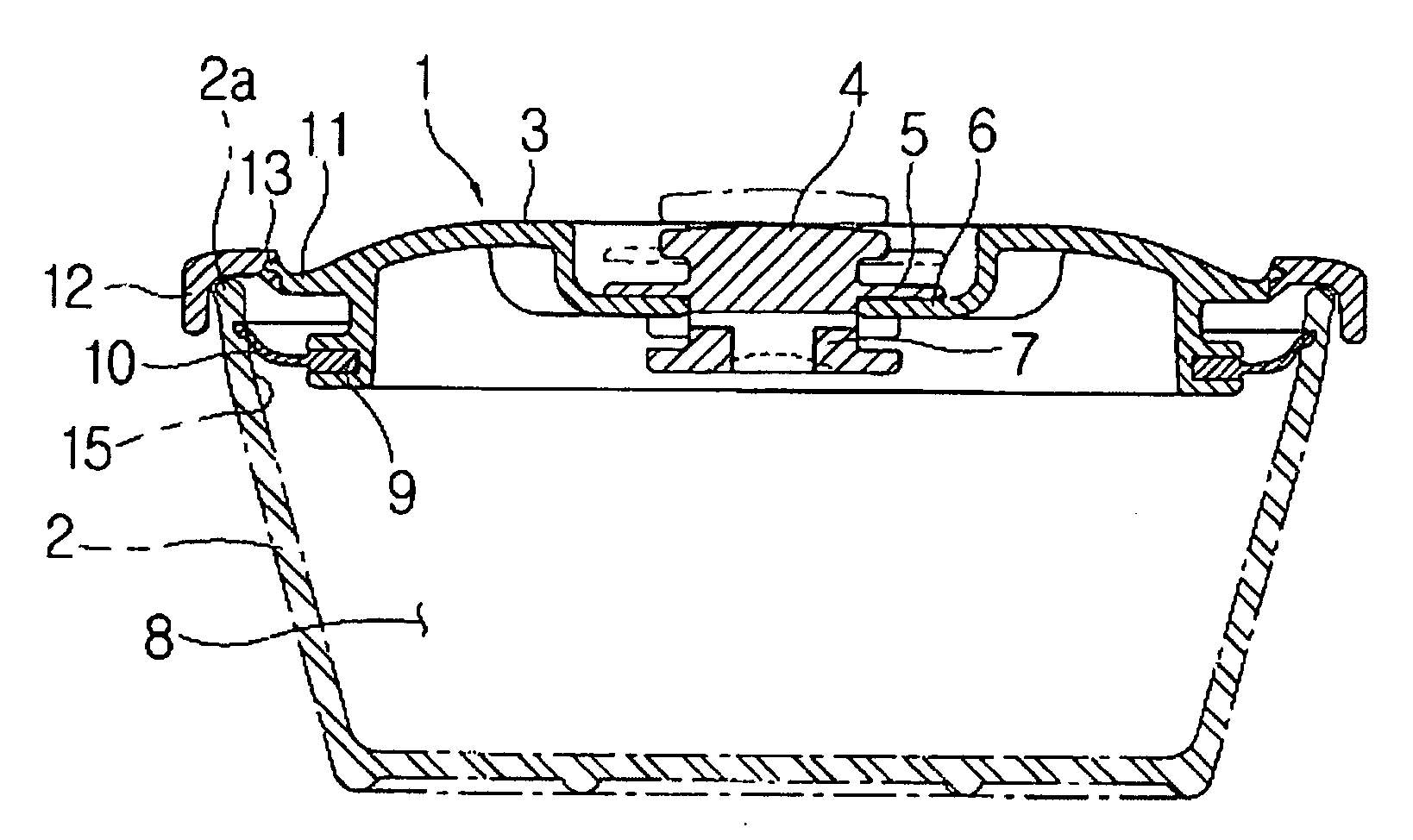

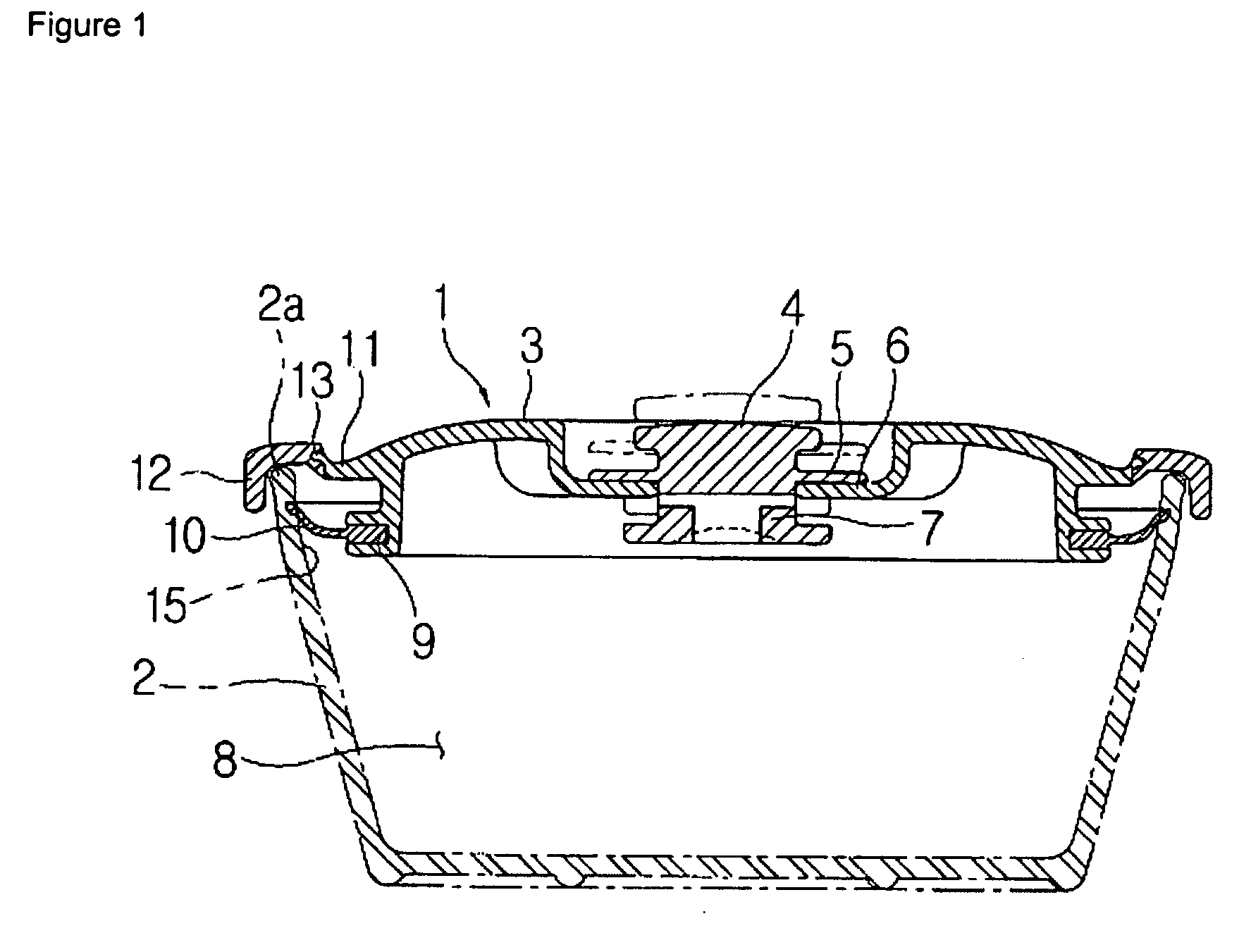

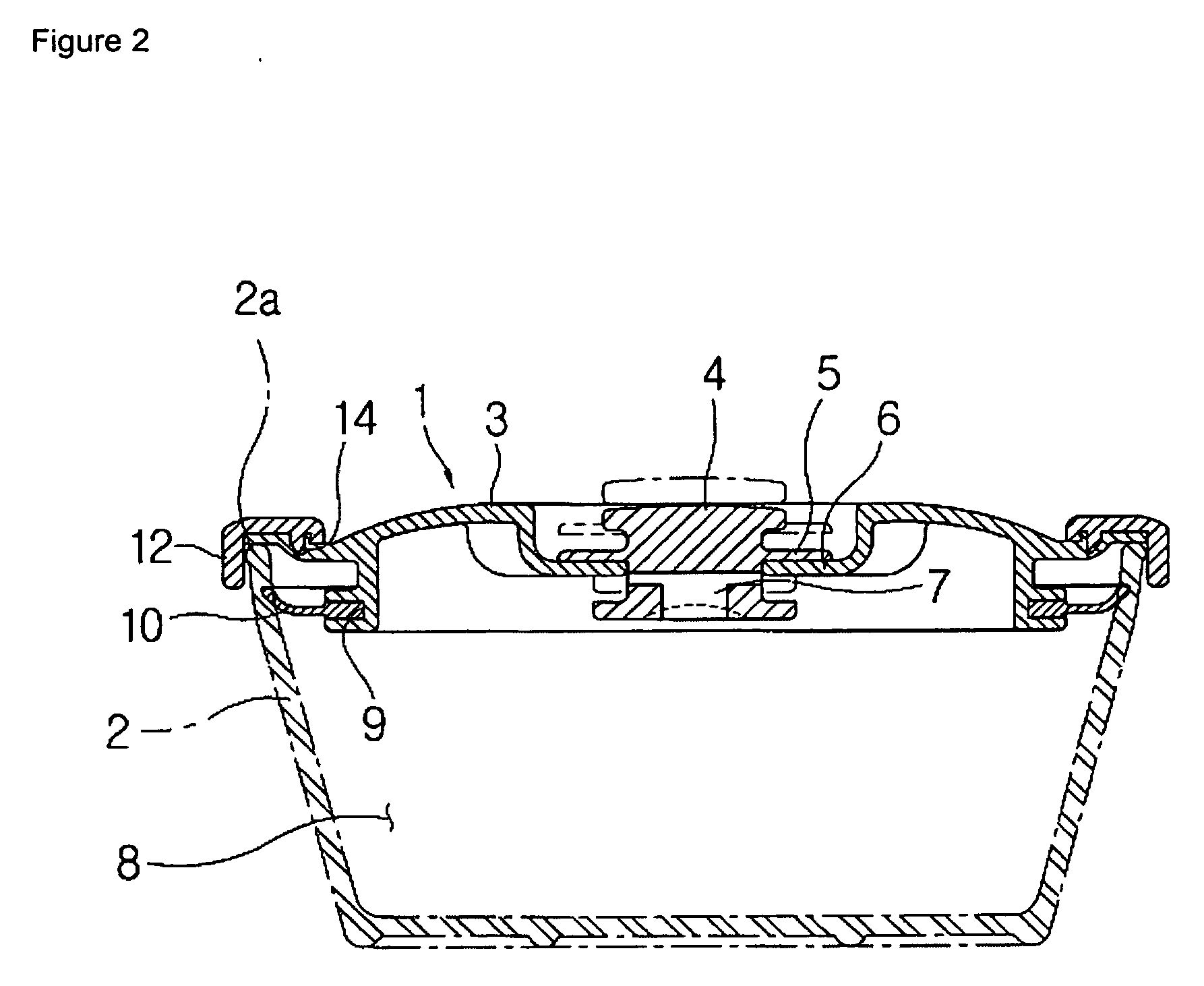

[0015]FIG. 1 is a view illustrating a sealed container lid of a vacuum valve operation type according to the present invention, and FIG. 2 is a view illustrating a dual injection structure of a sealed container lid of a vacuum valve operation type according to an embodiment of the present invention.

[0016] In the drawings, reference numeral 1 represents a container lid, and 2 represents a container body in which the container lid 1 is opened and closed.

[0017] A vacuum valve 4 for an opening and closing operation of a lid is engaged at a body 3 of the container lid 2. When a valve seat 5 of the vacuum valve 4 is lifted off the valve seat 6, the interior 8 of the container body 2 is opened through a valve hole 7 with respect to the outside. When it is pressed and is closely contacted with the valve seat 6, the valve hole 7 is closed, and the interior 8 of the container body 2 is disconnected with the outside.

[0018] A circular groove 9 is formed at the body 3 in a horizontal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com