Radial out-flowing rotary ram-in compressor

a compressor and ram-in technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of the practical useful range of operating rotational speeds and the inconvenience of use of the conventional type of positive displacement rotary compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

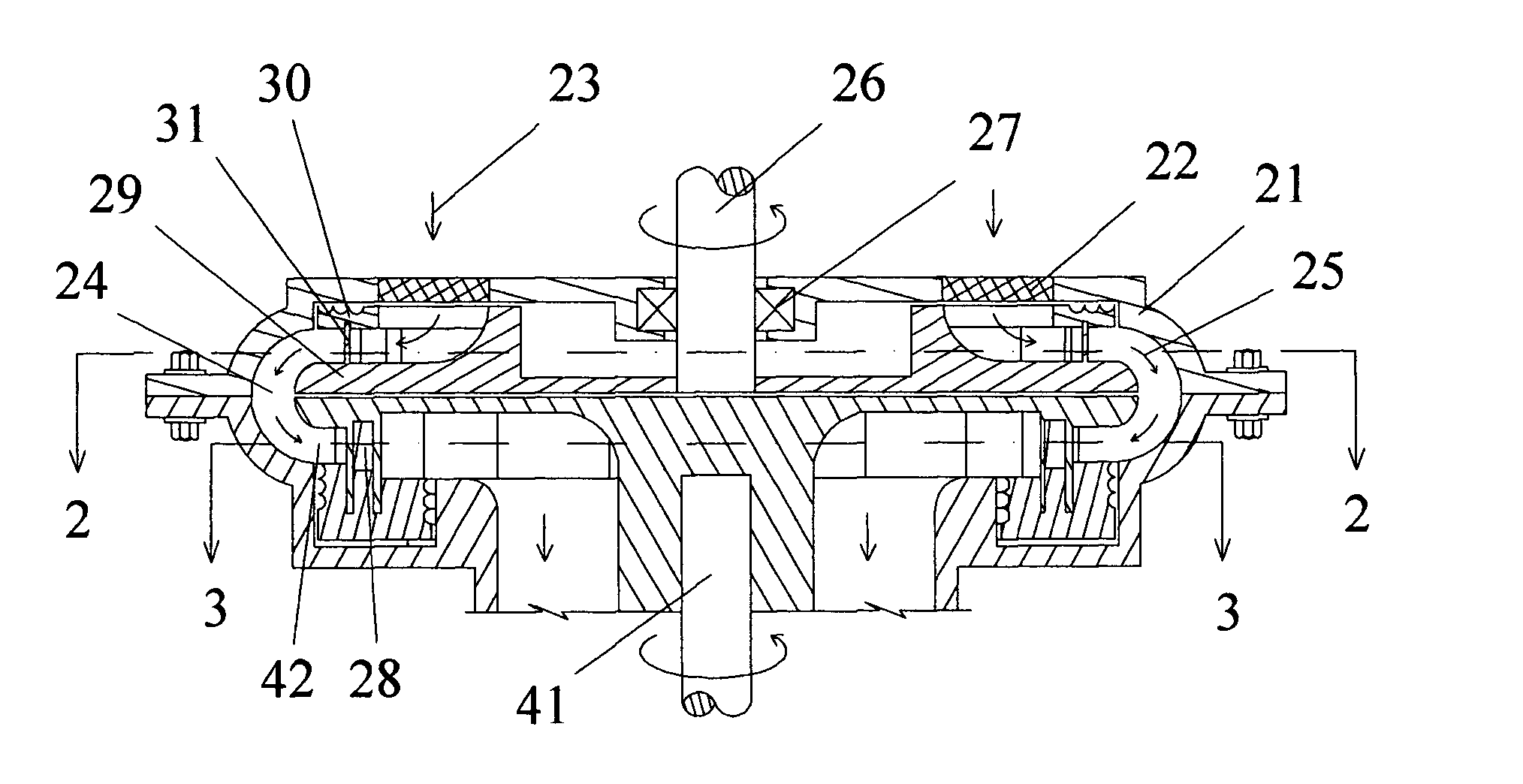

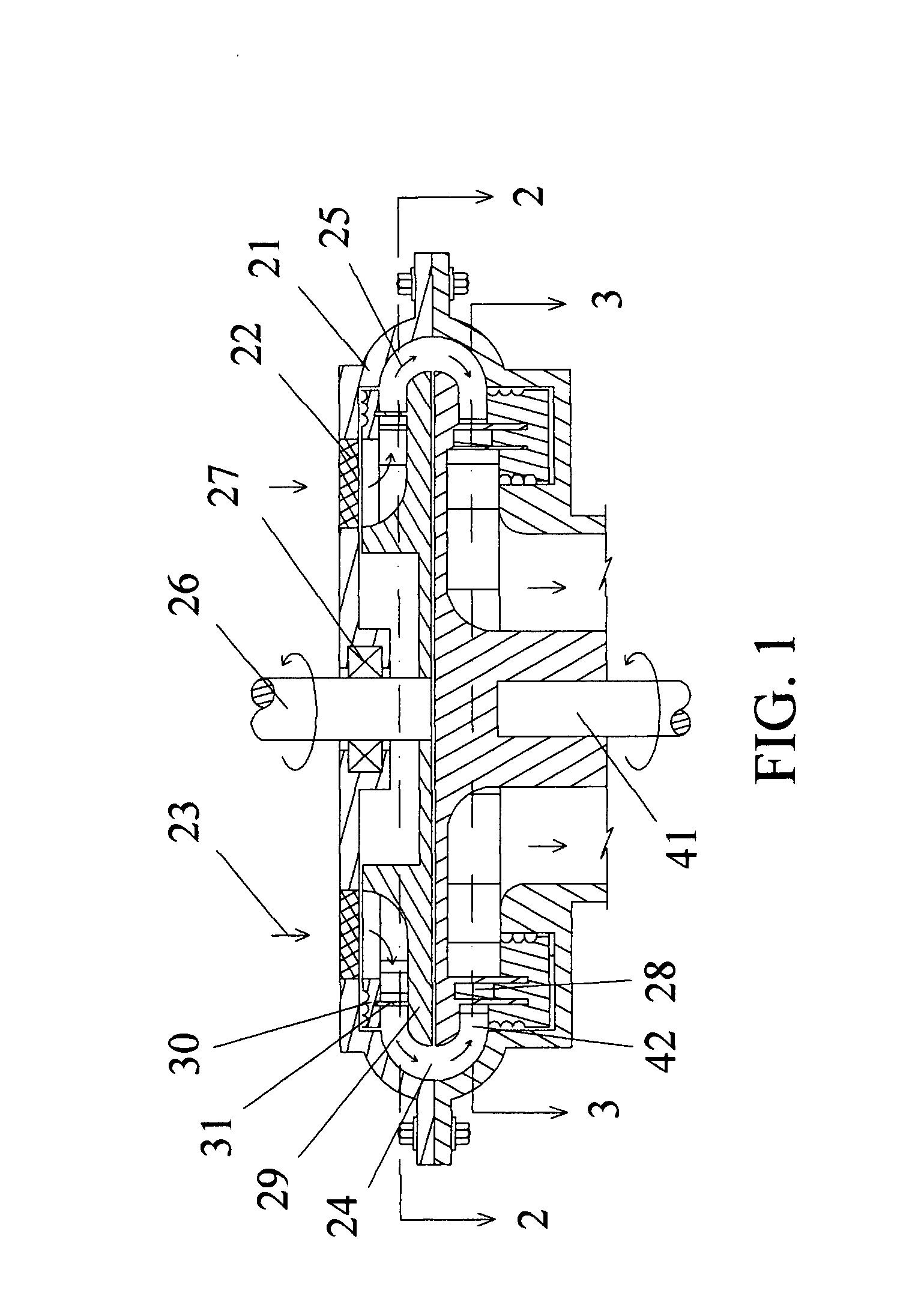

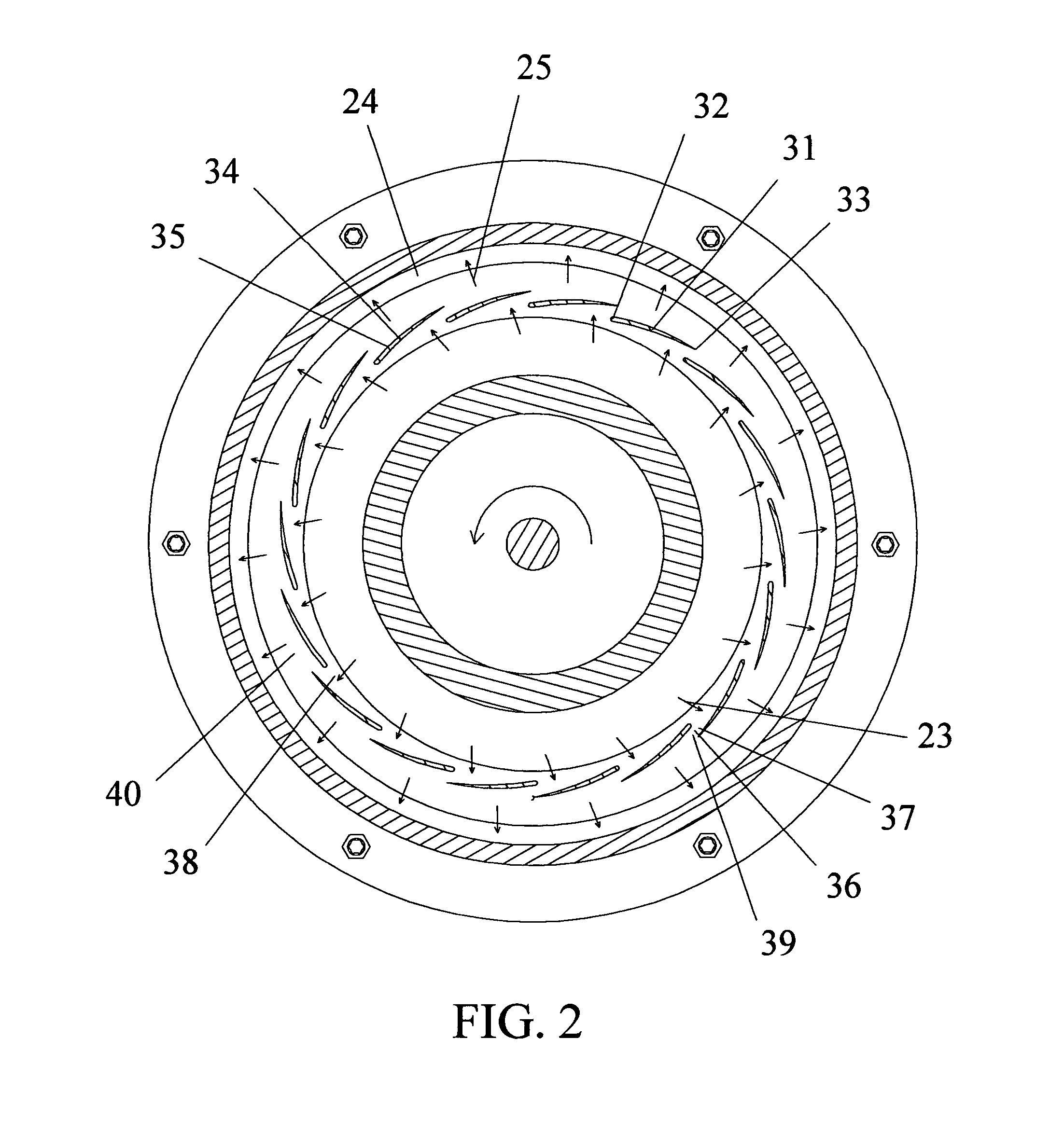

[0026] Prior filed U.S. patent application Ser. No.10 / 669,514, entitled “Rotary ram-in compressor” provides a rotary ram-in compressor for use in gas turbine engines, and the like, having a plurality of vanes attached to discs, with the opposing parts of each two adjacent vanes defining a feeding channel in-between. In operation, working gases are rammed through the feeding channels, followed by positive displacement of the rammed-in gases to a receiver wherein pressurized gases collect. The pressurized gases are actively swept from the receiver by either a successive rotary ram-in compressor or a successive rotary ram compressor (disclosed in the inventor's earlier International Patent Application Number: PCT / US00 / 17044, entitled “Rotary ram fluid pressurizing machine”). In the exemplary embodiments provided in the before mentioned prior patent application, working gases are displaced in a generally radially inward direction, which makes it inconvenient for use in the applications ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com