Hermetic compressor and manufacturing method of suction muffler

a manufacturing method and compressor technology, applied in the direction of positive displacement liquid engines, pumps, machines/engines, etc., can solve problems such as acoustic transmission loss, and achieve the effects of suppressing heat exchange, reducing noise, and further reducing sucking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

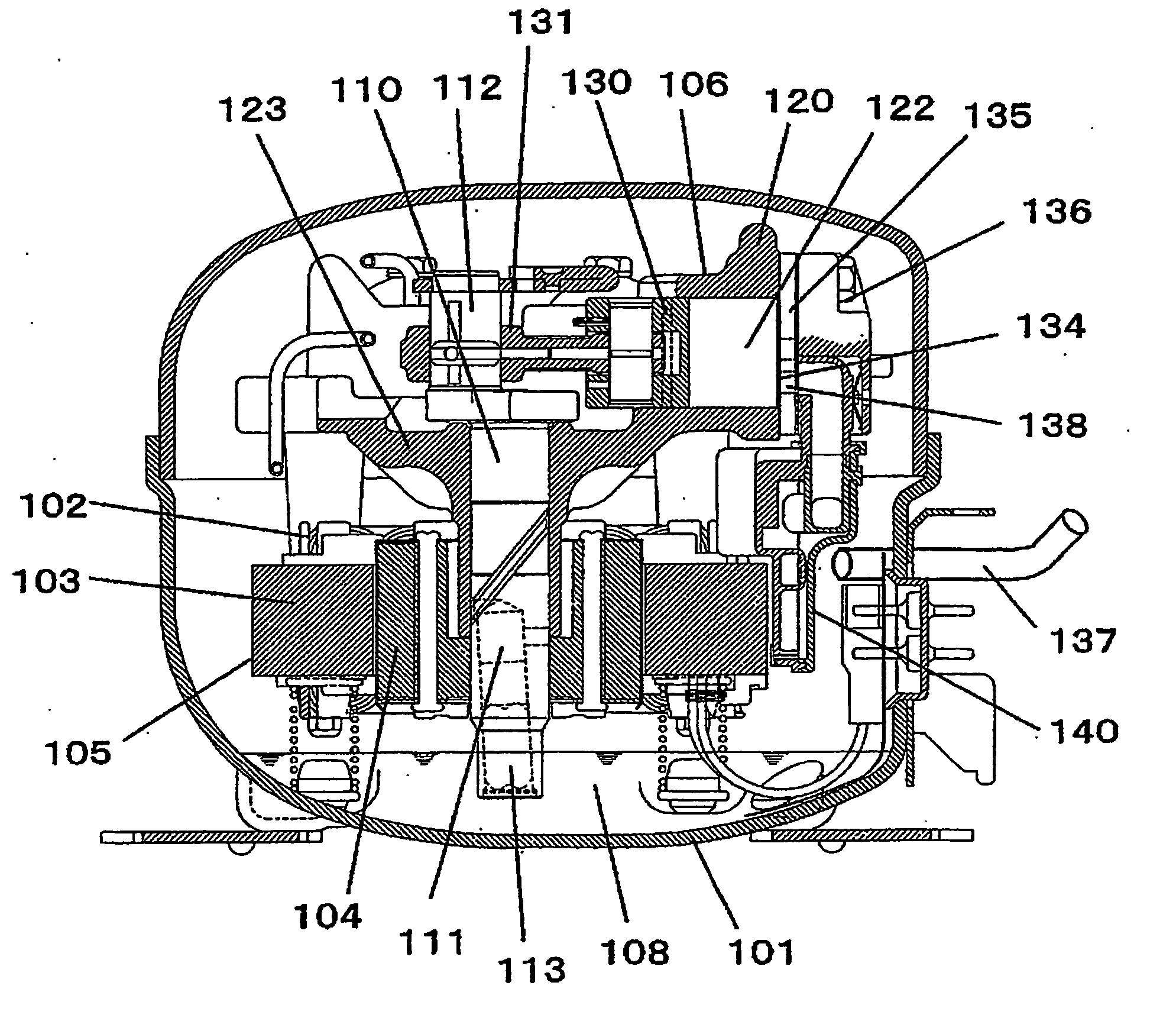

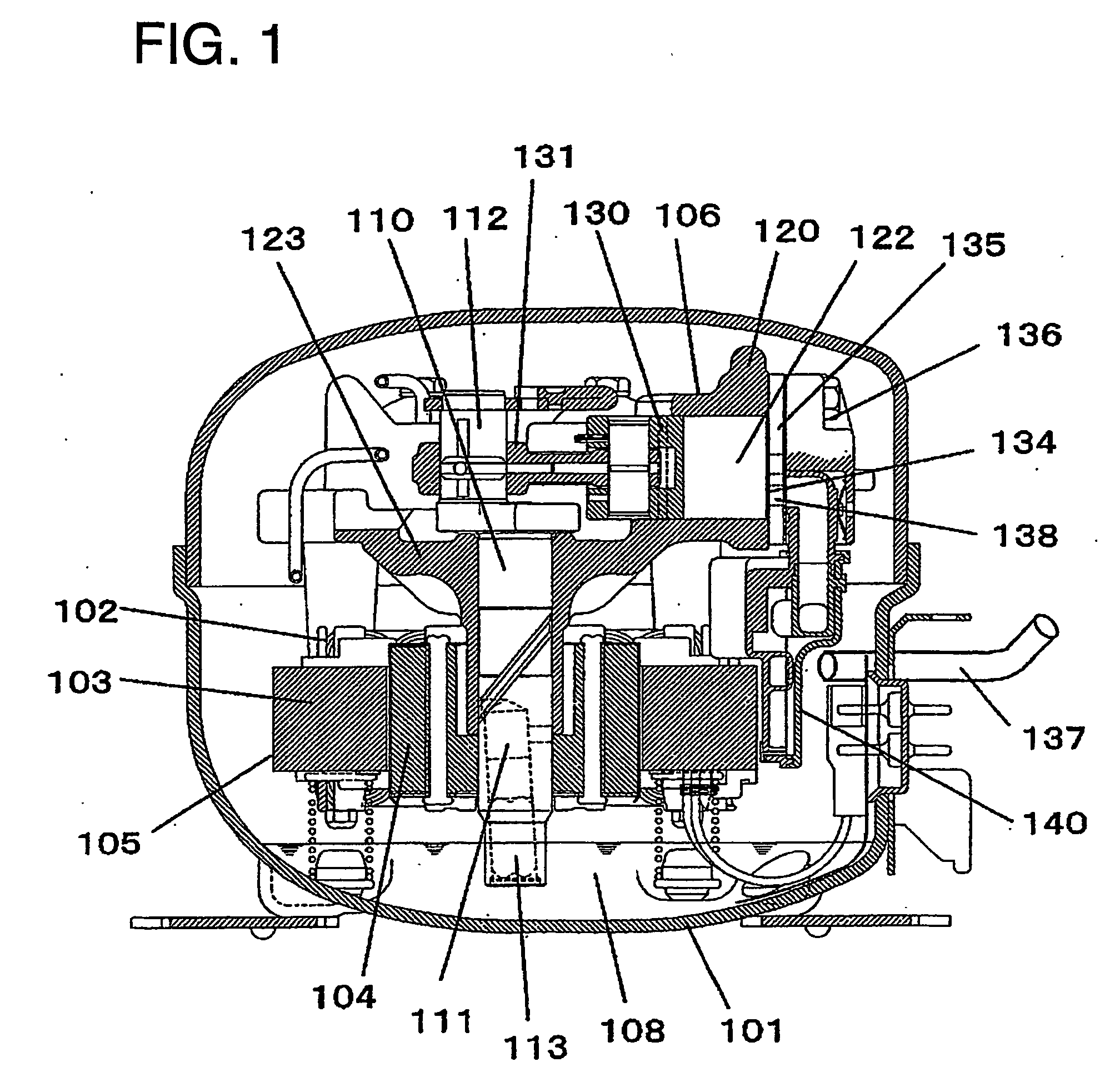

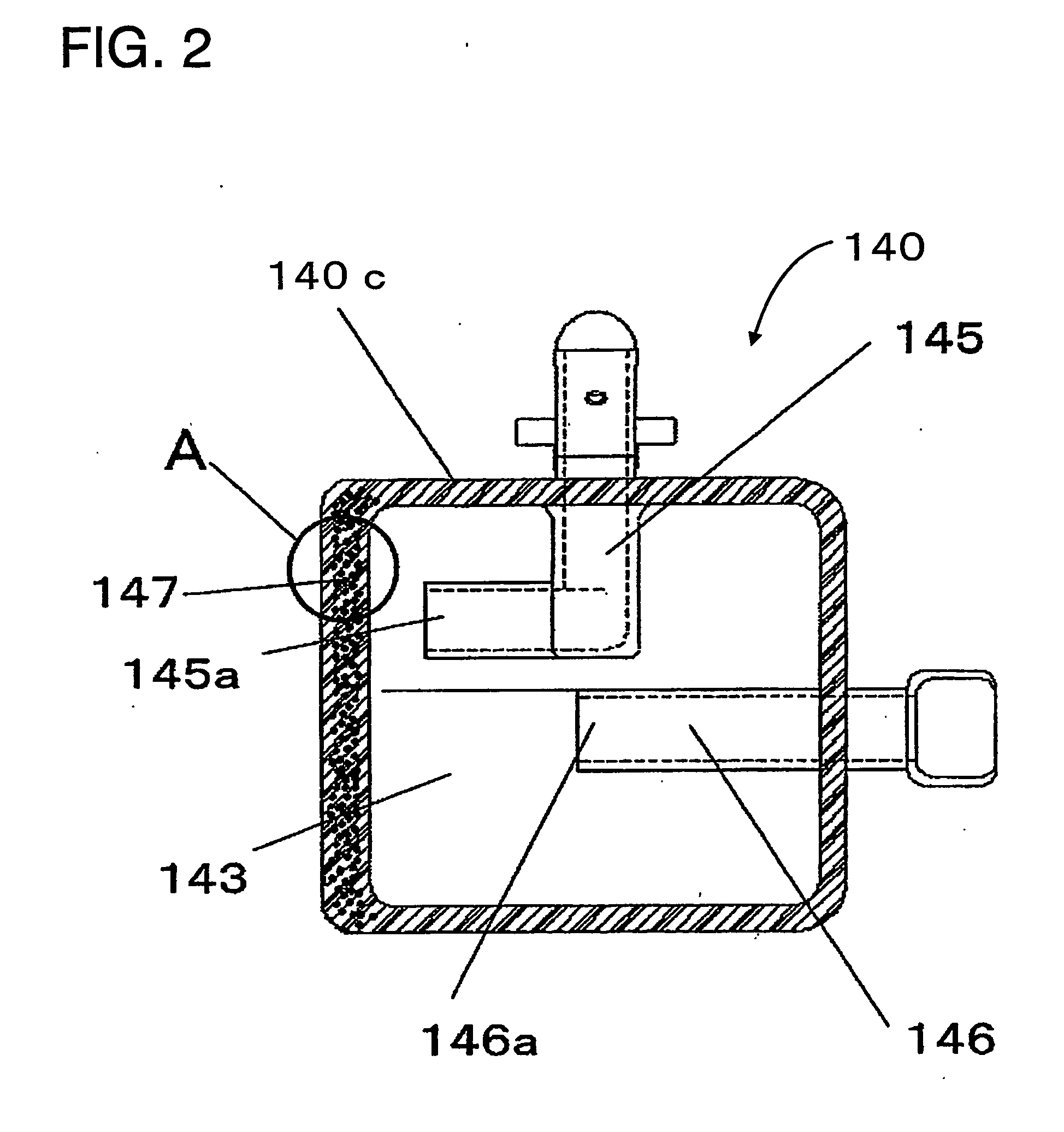

[0084]FIG. 1 is a sectional view of a hermetic compressor in the first embodiment of the present invention, and FIG. 2 is a sectional view of a suction muffler of the hermetic compressor in the same embodiment. FIG. 3 is an enlarged sectional view of a wall A-portion in FIG. 2. FIG. 4 is a main portion sectional view of a corner in the suction muffler in the same embodiment. FIGS. 5A to 5C are schematic configuration views of a foam molding machine in the same embodiment. FIG. 6 is a front view showing a suction muffler body and a runner in the same embodiment.

[0085] In FIG. 1, a hermetic vessel 101 accommodates: a motor element 105 composed of a rotator 104 and a stator 103 holding a coil portion 102; and a compression element 106 driven by the motor element 105. A lubricating oil 108 is stored in the hermetic vessel 101. By the way, as refrigerant gas (not shown), R600a of natural refrigerant is used.

[0086] Also, the motor element 105 is driven by an inverter method including a ...

second embodiment

[0122]FIG. 7 is a sectional view of a suction muffler of a hermetic compressor in the second embodiment of the present invention, and FIG. 8 is an enlarged view of a foaming portion of the suction muffler in the same embodiment. FIG. 9 is a rear view of a suction muffler body in the same embodiment, FIG. 10 is a decomposed perspective view of the suction muffler of the hermetic compressor in the same embodiment, and FIG. 11 is an enlarged view of a bonding section between a cover and the suction muffler body in the same embodiment. FIGS. 12A to 12C are schematic configuration views of a supercritical foam molding machine in the same embodiment. By the way, the configuration of the hermetic compressor in this embodiment is the same configuration as the first embodiment except the suction muffler. Thus, the explanation is omitted.

[0123] As shown in FIG. 7, the suction muffler 240 has a casing 240C composed of a plurality of walls, a first linkage path 245 and a second linkage path 24...

third embodiment

[0143]FIG. 13 is a sectional view of a hermetic compressor in the third embodiment of the present invention, and FIG. 14 is a decomposition view of a suction muffler in the same embodiment. FIGS. 15A to 15C are schematic configuration views of a supercritical foam molding machine in the same embodiment. By the way, the configuration of the hermetic compressor in this embodiment is the same configuration as the second embodiment, except the suction muffler. Thus, the explanation is omitted.

[0144] A suction muffler 340 is composed of three parts of a motor element side 341, an anti-motor element side 342 and a center 343. Most of the portions of their elements constitute a casing 340C. The suction muffler 340 where the three parts of the motor element side 341, the anti-motor element side 342 and the center 343 are combined has a first linkage path 345 and a second linkage path 346, and a sound attenuation space 347 is formed inside the casing 340C. Also, the first linkage path 345 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com