Gas turbine gearbox

a technology of gas turbines and gearboxes, applied in the direction of gearboxes, machines/engines, efficient propulsion technologies, etc., can solve the problems of increasing production, inventory, etc., and achieve the effect of reducing duplication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

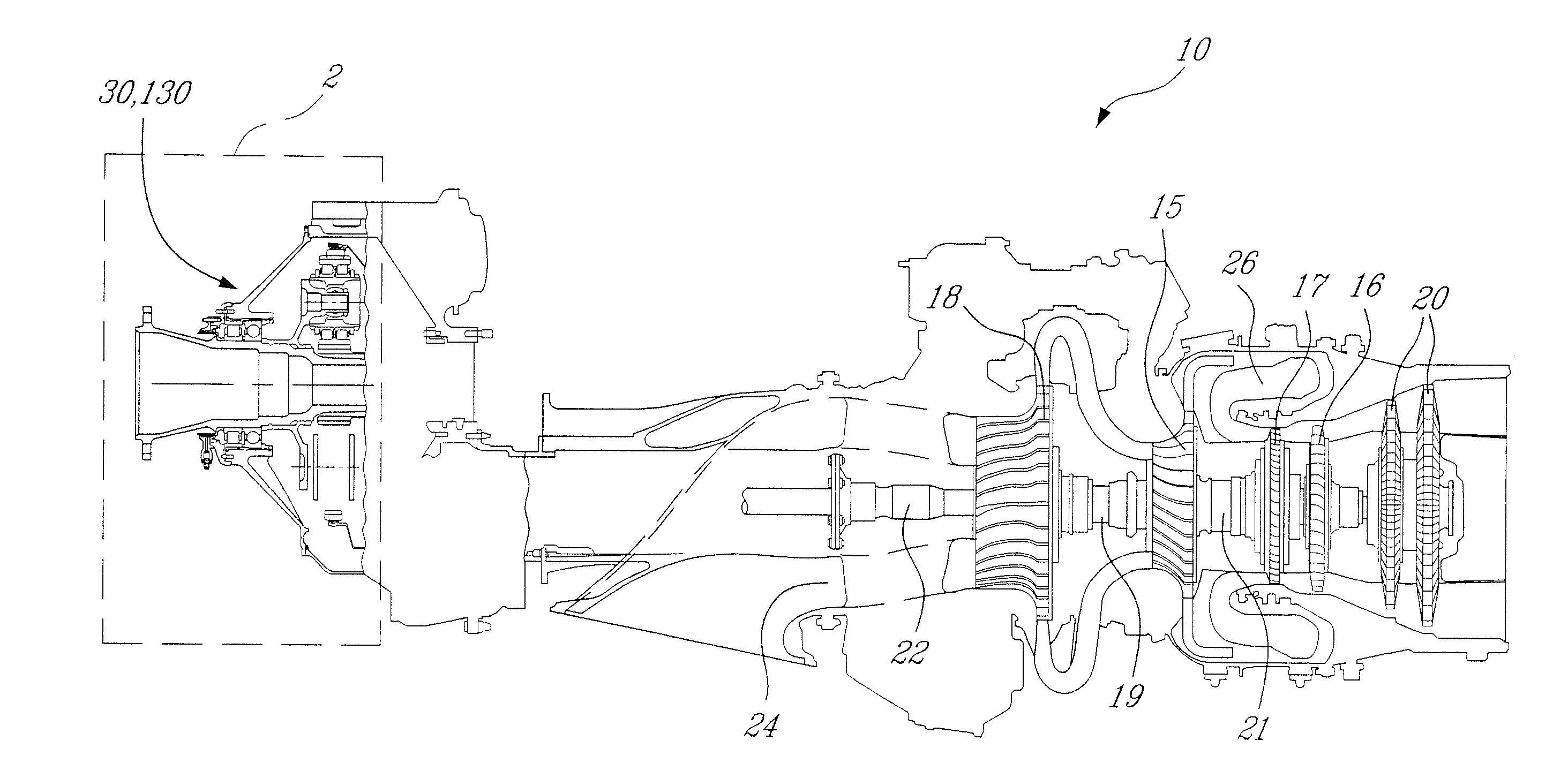

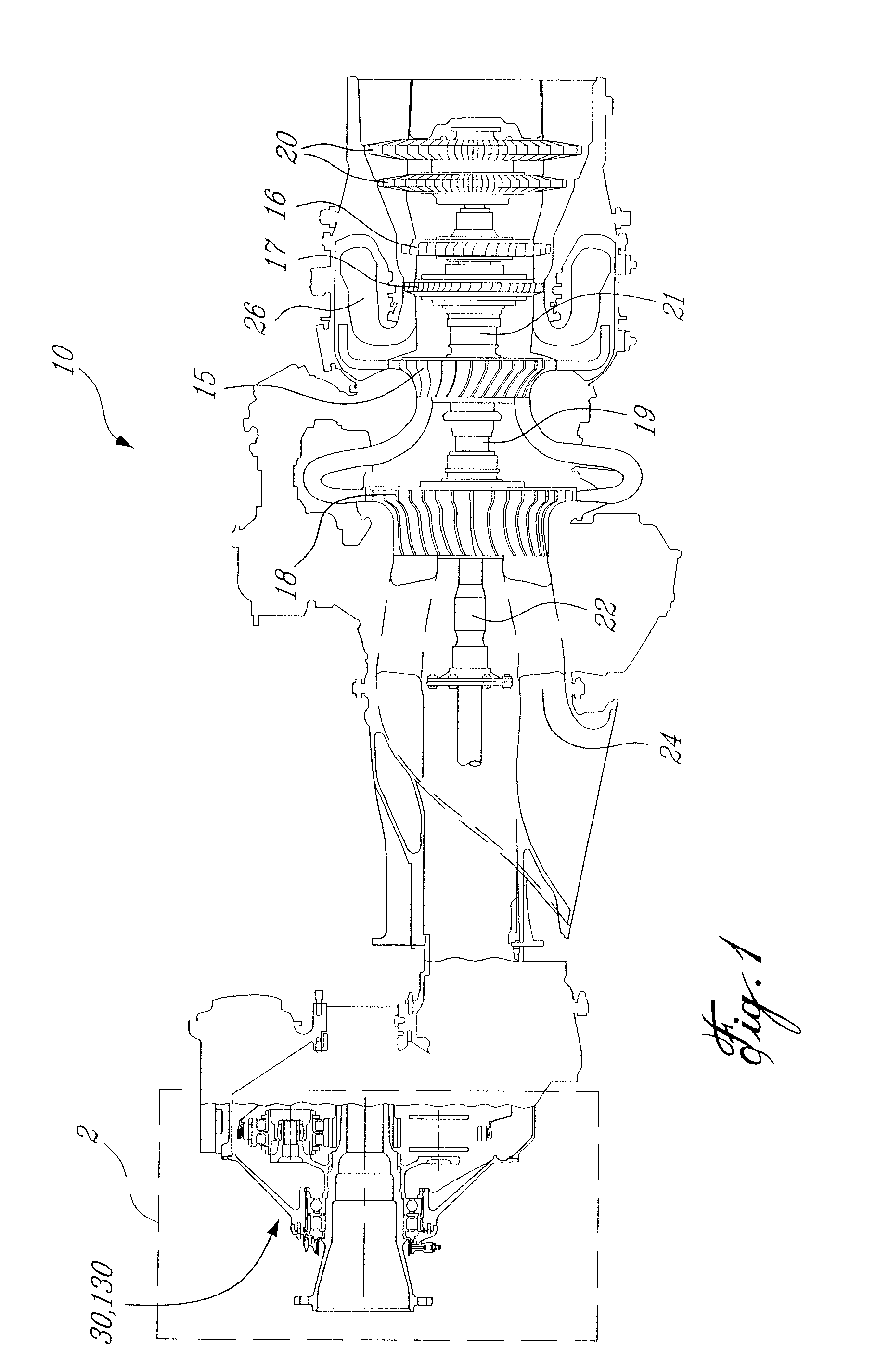

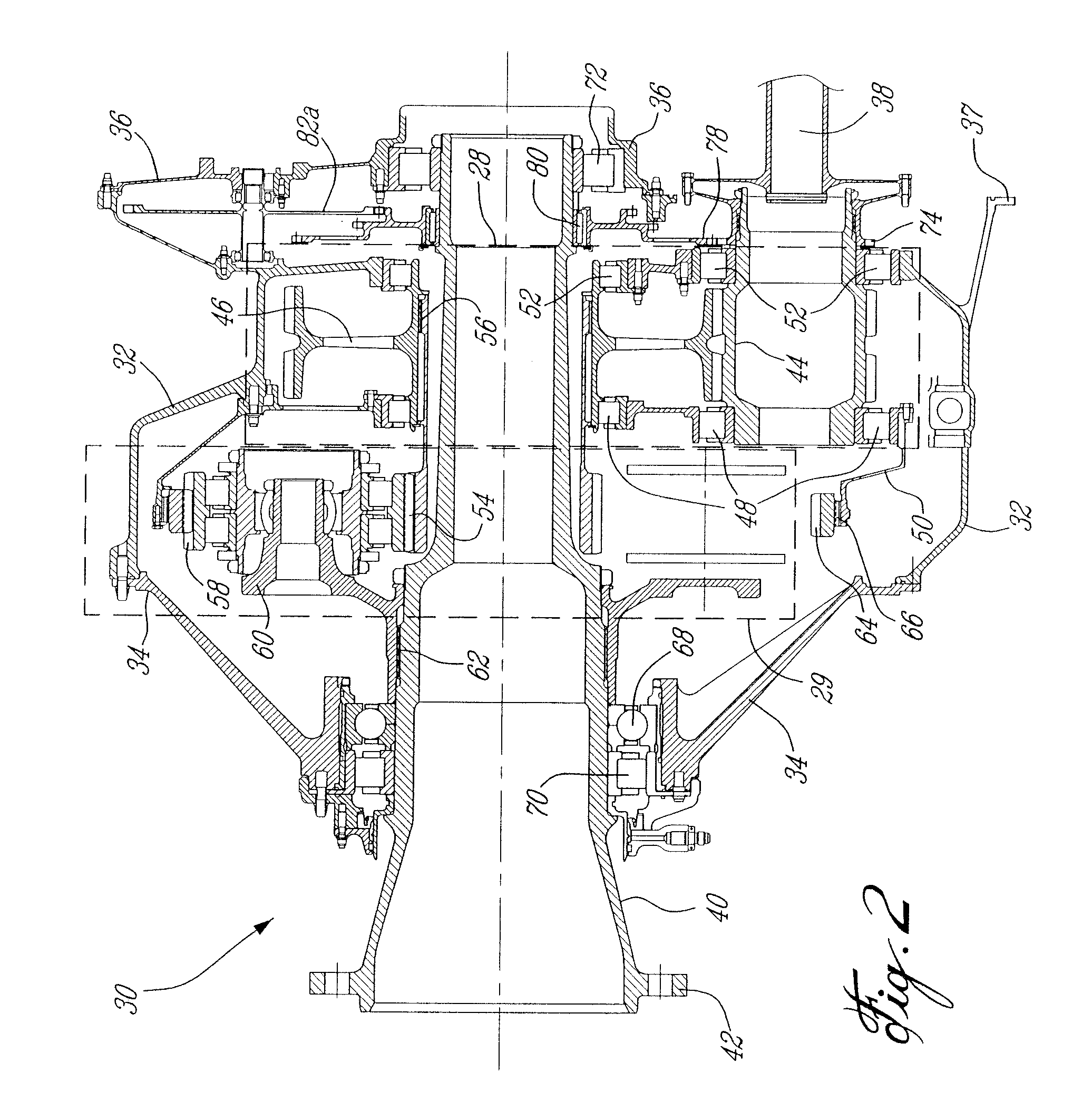

[0018]FIG. 1 illustrates a turboprop engine 10 having an offset gearbox 30,130 for driving a propeller. The engine 10 comprises a first rotating assembly including a low pressure (LP) turbine 16 and a LP compressor 18 mounted on an LP turbine shaft 19, and a second rotating assembly including a high pressure (HP) turbine 17 and a HP compressor 15 mounted on a HP turbine shaft 21. Power turbines 20 drive a power turbine output shaft 22, which provides rotational input into the gearbox 30,130.

[0019] The LP and HP compressors 18,15 draw air into the engine 10 via an annular air inlet passage 24, increasing its pressure and delivering the compressed air to a combustor 26 where it is mixed with fuel and ignited for generating a stream of hot combustion gases. The LP and HP turbines 16,17 extract energy from the hot expanding gases for respectively driving the LP and HP compressors 18,15. The hot gases leaving the LP and HP compressor turbines are accelerated again as they expand through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com