Fuel tank and filler packet for dispersing ballistic shock

a technology of ballistic shock and filler packet, which is applied in the field of receptacles, can solve the problems of easy penetration of shock absorbing padding and tank disintegration, and achieve the effect of resisting disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

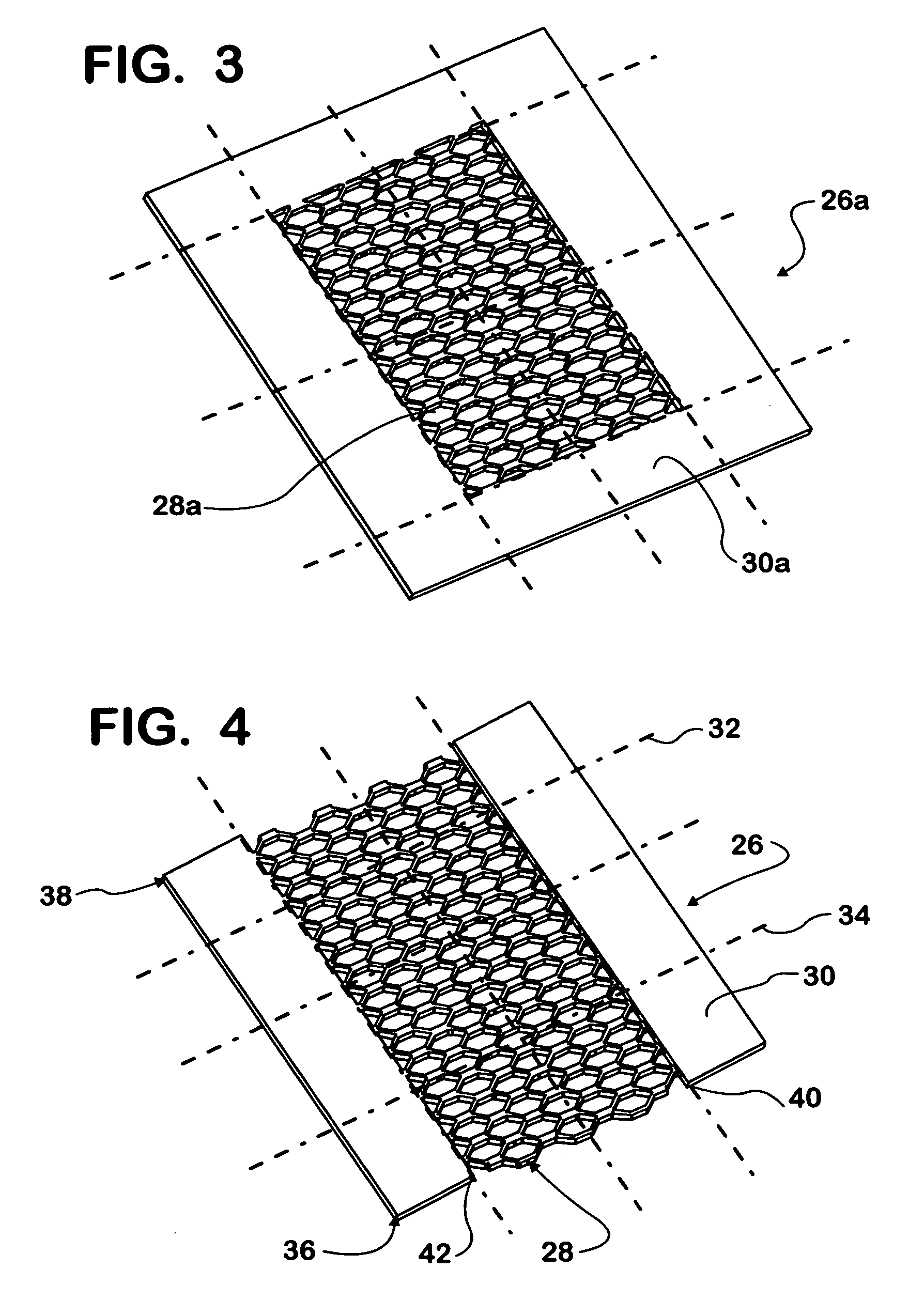

[0026] Turning first to FIG. 1 there is shown a tank 12 in accordance with the present invention having filler packets 14 positioned within the interior thereof. These packets are preferably thermally conductive and positioned in thermal contact with the exterior walls 16 of the tank to thereby dissipate heat from the tank wall, as is now well known in the art. In the preferred embodiment, the individual filler packets 14 of the present invention (one embodiment of which is shown in FIG. 2) each exhibit a thermally conductive porous fuel permeable body portion 18 for accommodating fuel within the tank and suppressing explosion by thermal conduction. However, for suppressing ballistic shock, a denser portion or member 20 is provided within each packet 14, which denser portion or member 20 has a greater mass density than that of the sheet of foil material in its unexpanded state used for the outer body portion 18, as more fully described below.

[0027] Formation of one embodiment of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com