Conveying apparatus of a vehicle washing machine

a technology of conveying apparatus and vehicle washing machine, which is applied in the direction of transportation and packaging, train hauling devices, rope railways, etc., can solve the problems of weaker affecting serious running safety, and two lateral sides of tires being scratched, so as to prevent the sewage from containing and prevent the lateral side of wheels from being worn ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described with reference to the accompanying drawings.

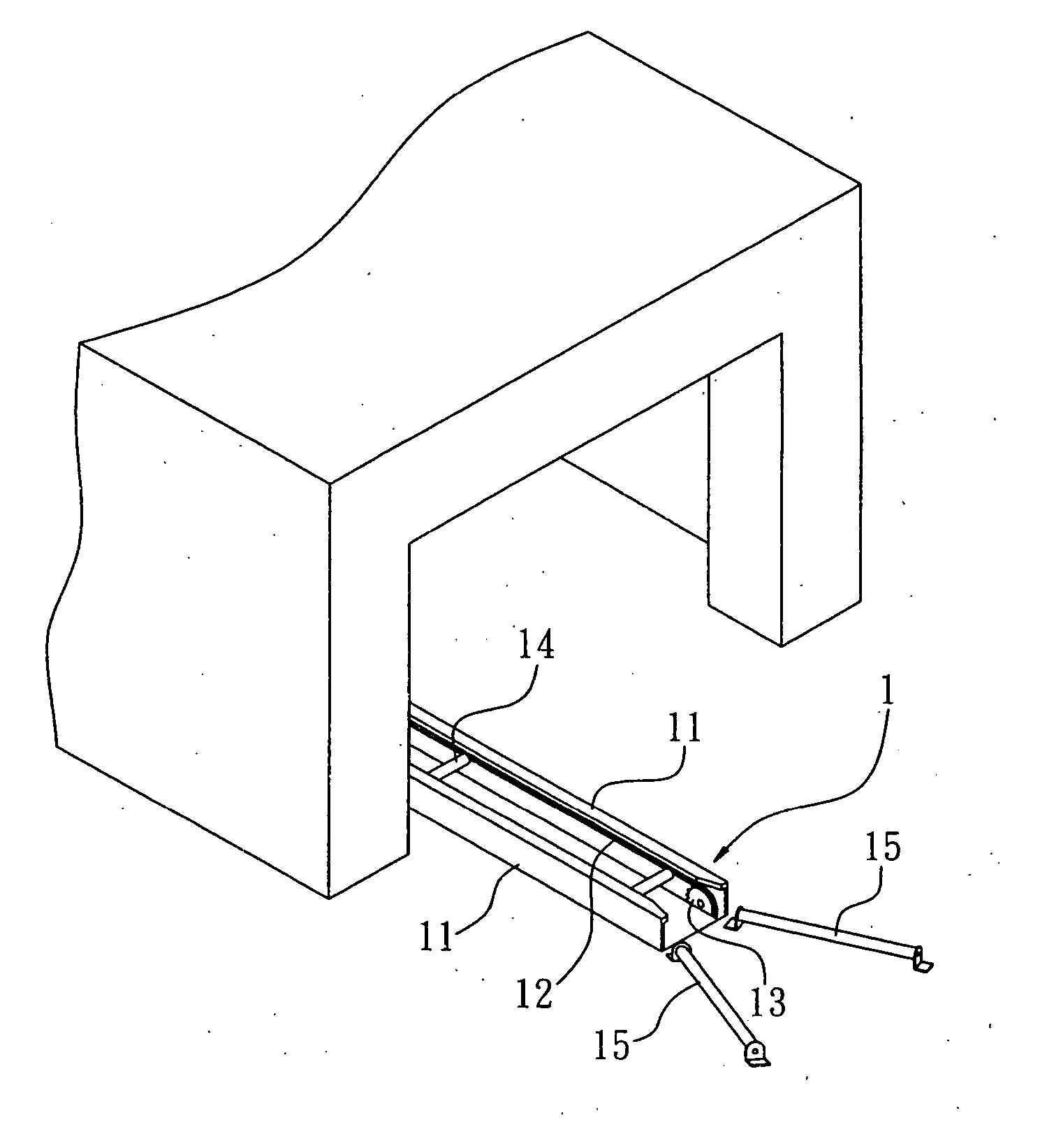

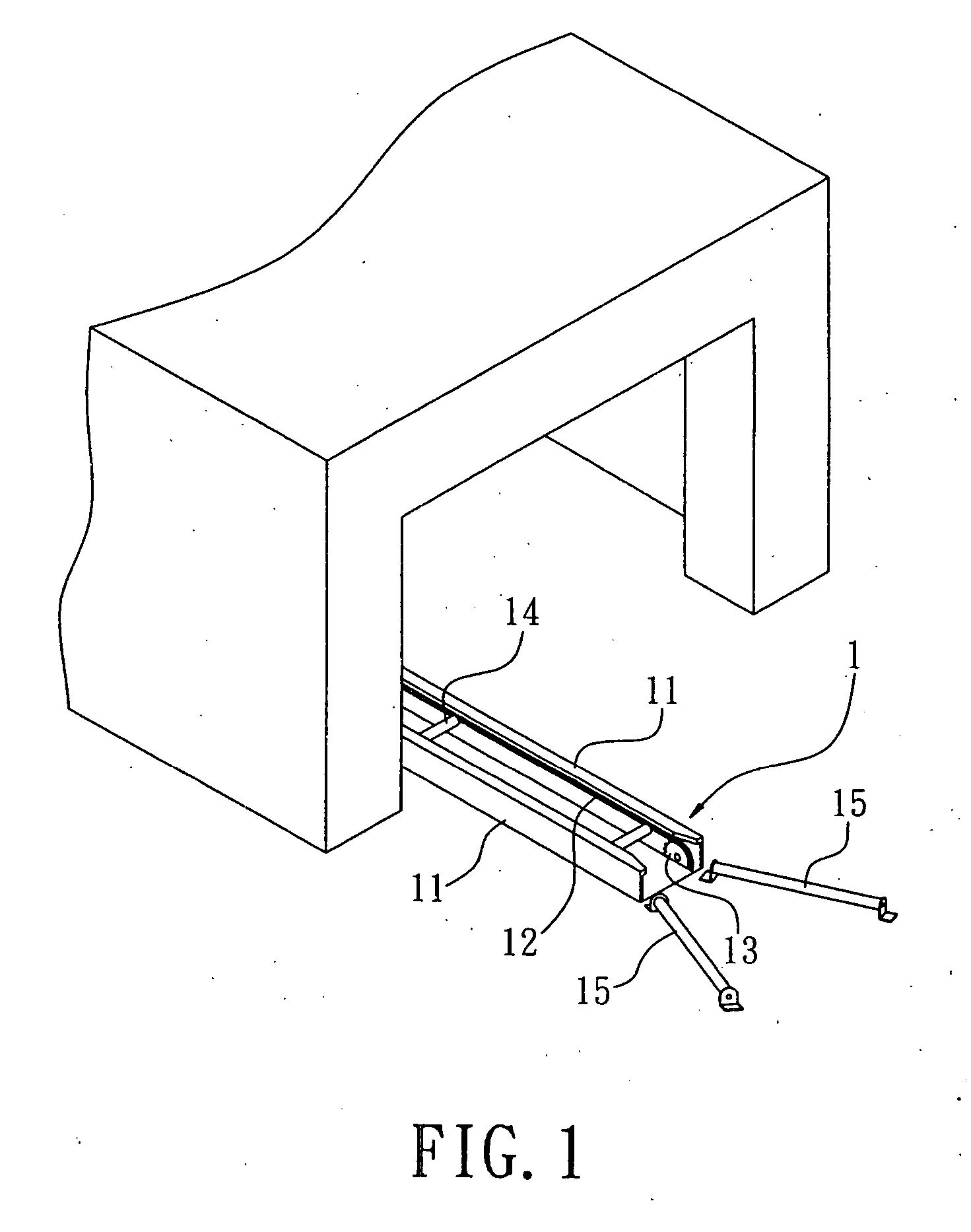

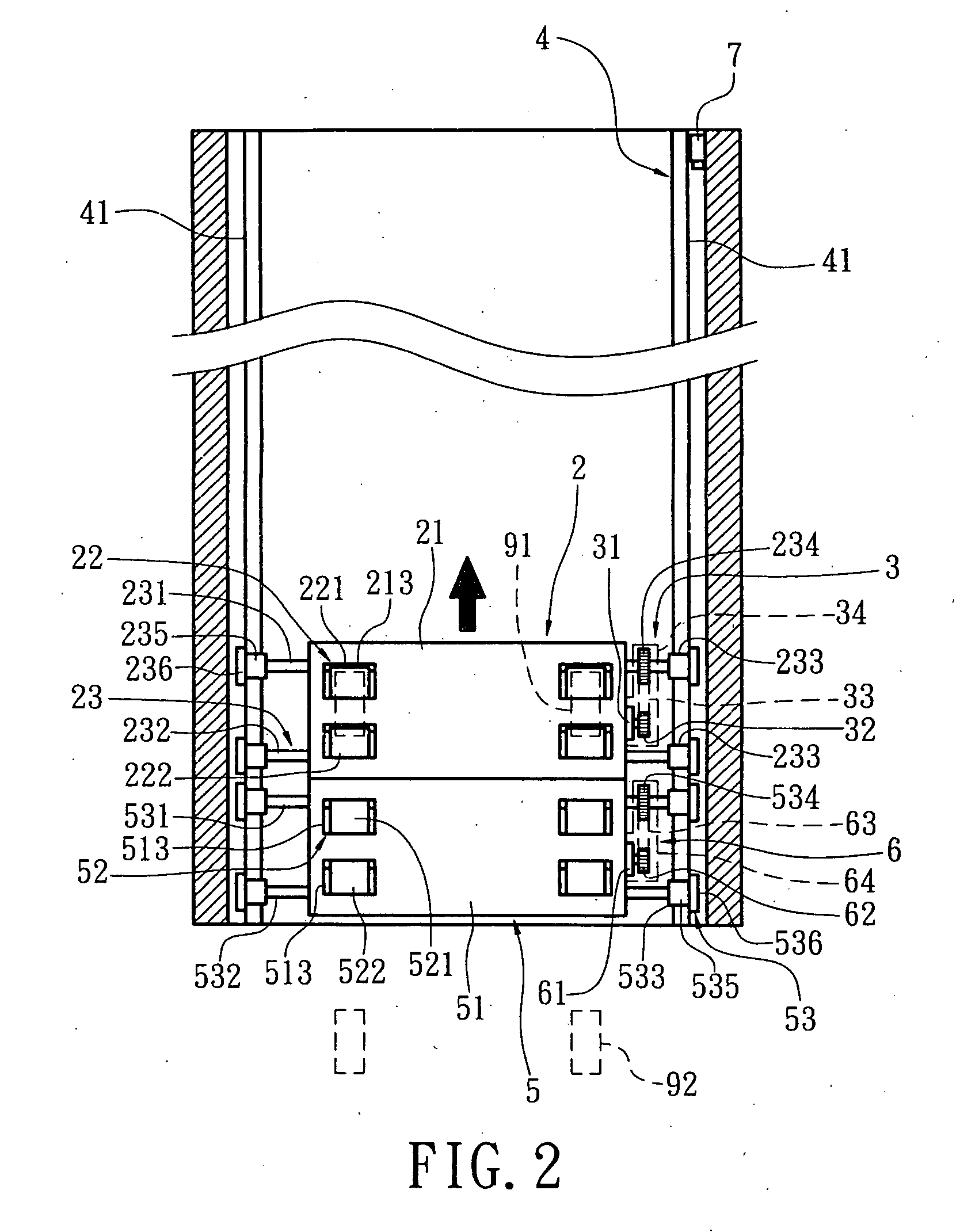

[0020] Referring to FIGS. 2 and 3, a conveying apparatus of a vehicle washing machine according to a preferred embodiment of the invention can convey a vehicle 9 into the vehicle washing machine by positioning front and rear wheels 91 and 92 of the vehicle 9. The apparatus includes a first carrying mechanism 2, a first driving mechanism 3, a guiding mechanism 4, a second carrying mechanism 5, a second driving mechanism 6 and a sensor device 7.

[0021] The first carrying mechanism 2 has a base 21, two positioning devices 22, which are disposed on the base 21 and can position the front wheels 91 of the vehicle 9, and a moving device 23 disposed on the base 21. The base 21 has a rectangular hollow frame 211 having a top plate 212 formed with front and rear mounting holes 213 on each of left and right sides of the top plate 212. Each positioning device 22 has a front pressing plate 221 and a rear resistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com