Open ended interlocking block system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

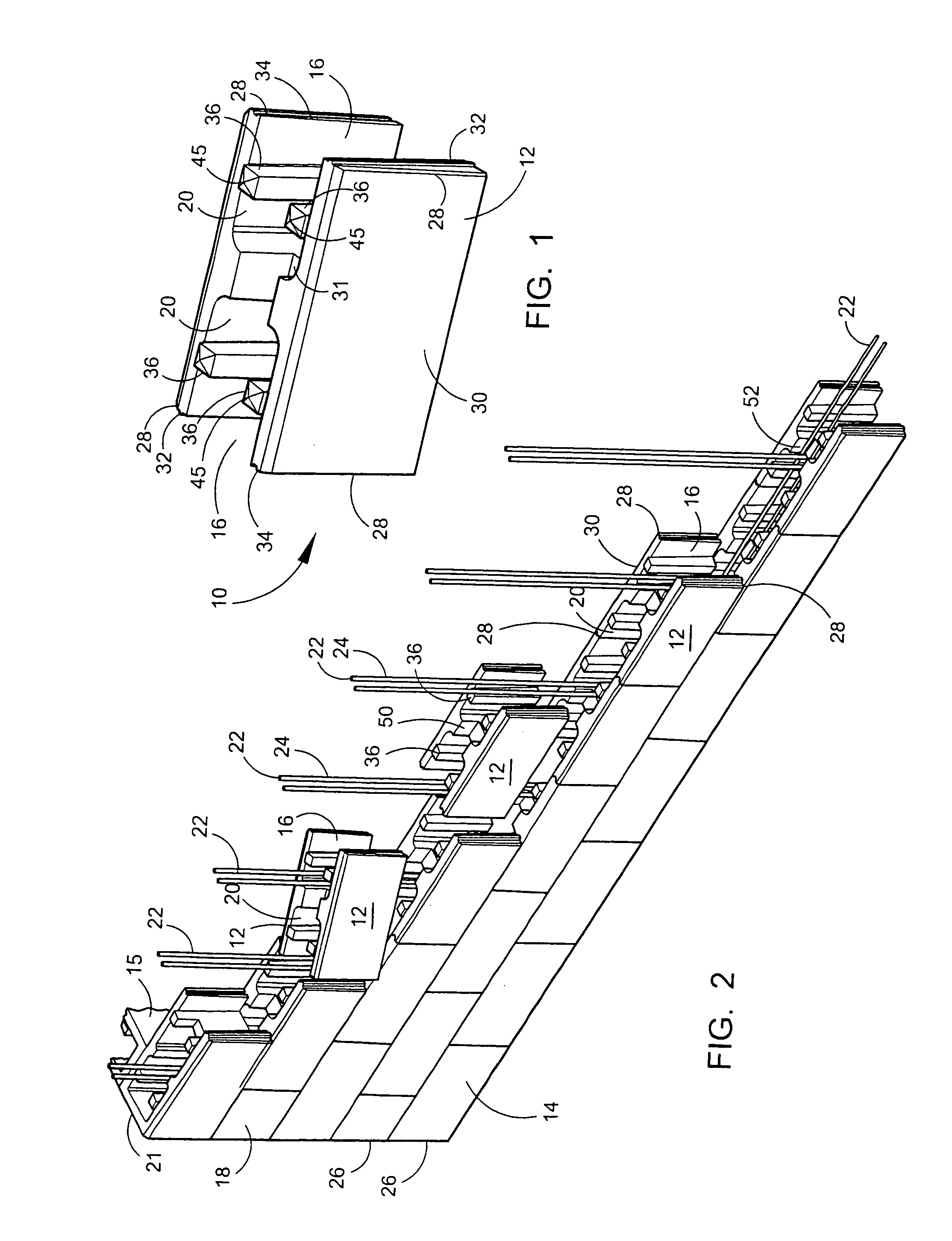

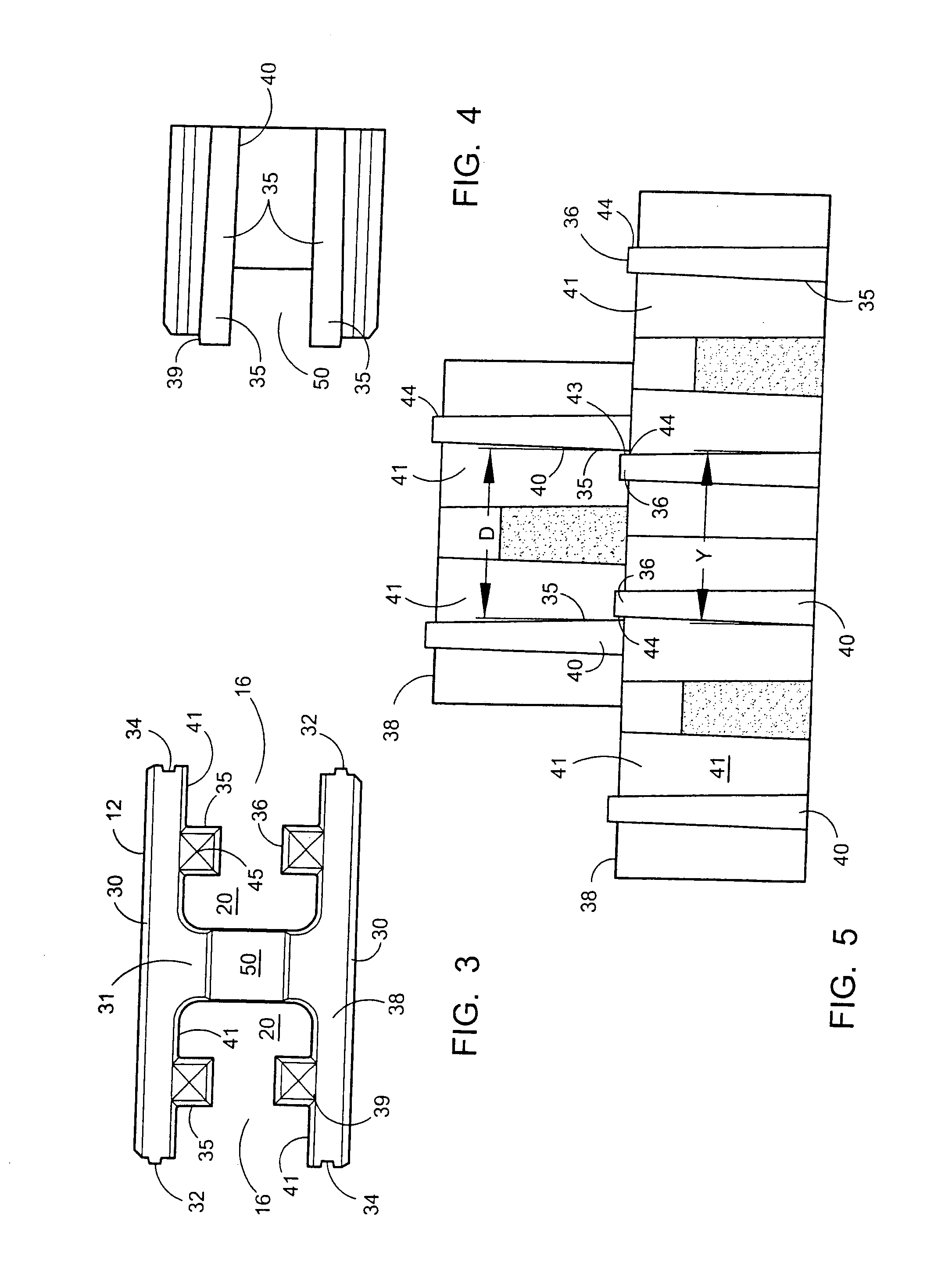

[0031] As shown in FIGS. 1-8, the device employs a one block building system providing for building of a wall structure formed of single interlocking block style. The device 10 provides great utility in the building of walls with interlocking blocks 12 as shown in FIGS. 2 and 6, using a generally “H” shaped primary blocks 12 which can be employed as the sole block used in building a wall 14. The block 12 is formed in this shape by a pair of parallel sidewalls 30 extending from a middle portion 31. The primary block 12 will allow for the building of straight walls or walls with corners engaged to traverse walls 15 where the primary block 12 would be employed as a corner block anchoring the walls perpendicular to each other.

[0032] When employed as a one block method or system, the primary block 12, on a retaining wall can have its opposing open ends 16, at both termination points at the sides of the wall, filled with mortar or concrete or simply left open and filled with adjacent soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com