Steam power plant

a steam power plant and steam technology, applied in steam engine plants, indirect carbon dioxide mitigation, machines/engines, etc., can solve the problems of limited steam temperature, thermal transfer of hot gas to the medium to be heated, and limited steam temperature permissible, so as to achieve fast output regulation and high steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

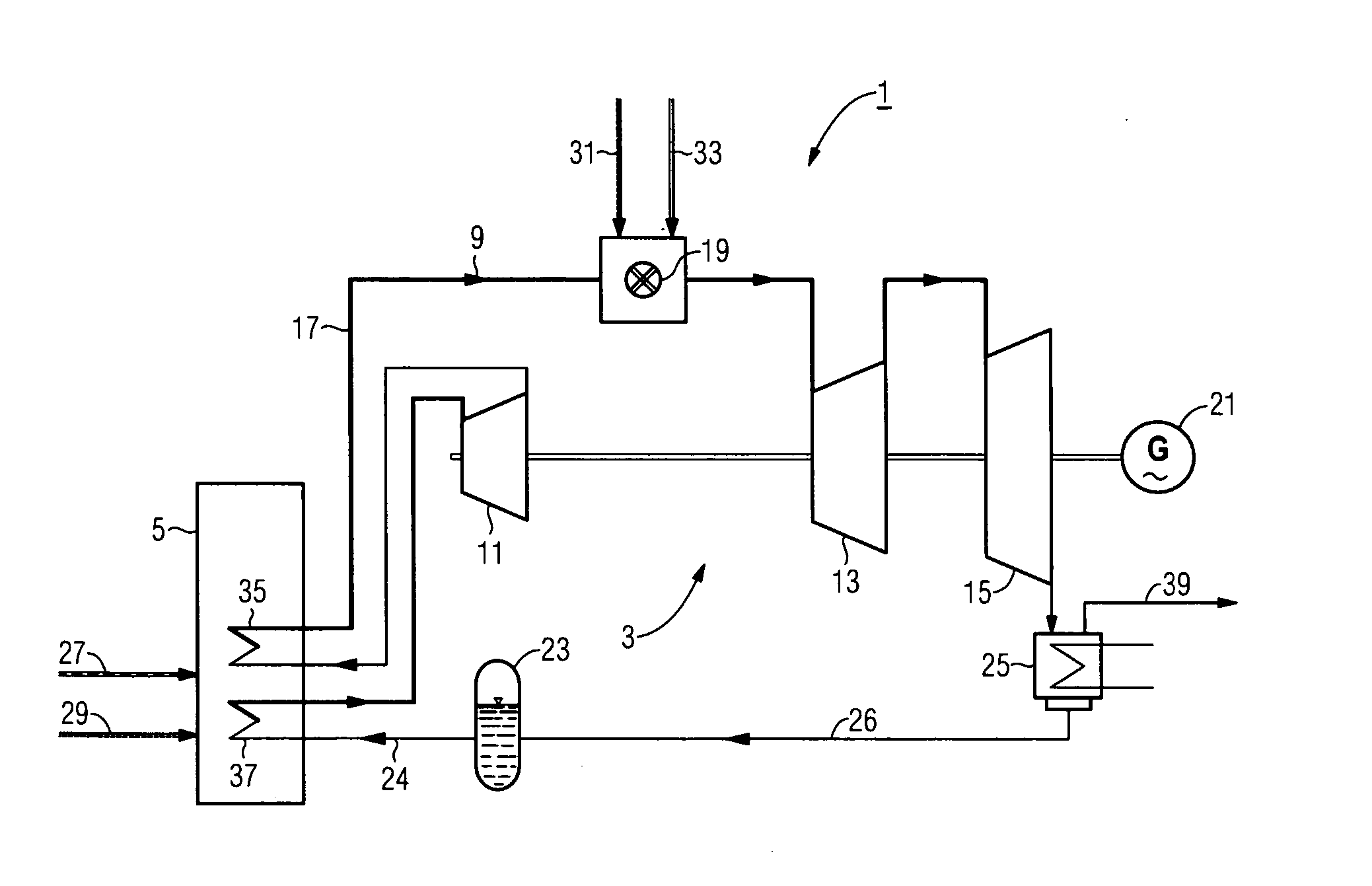

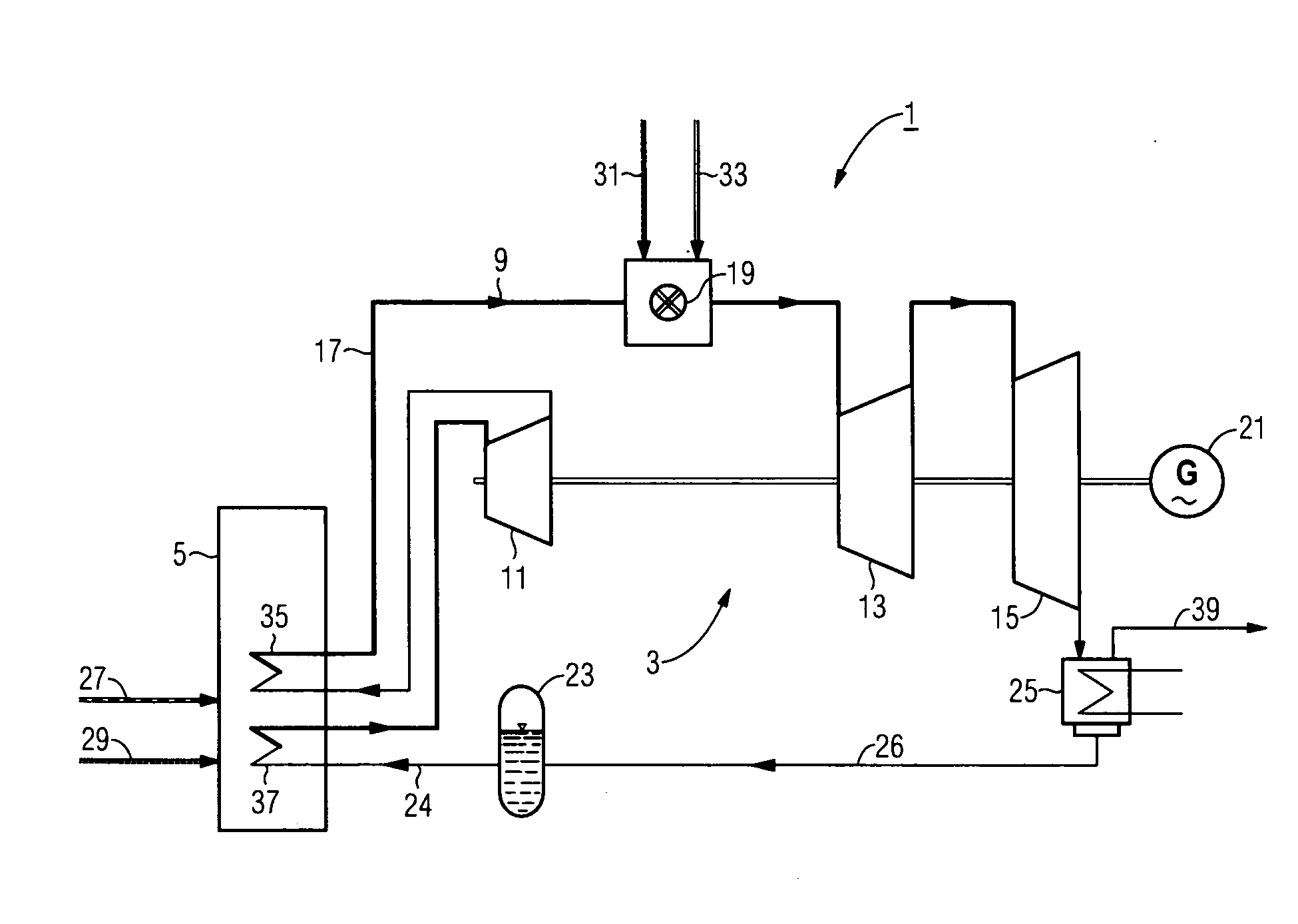

[0031] The FIGURE shows a claimed steam power plant 1, having a steam turbine 3 coupled to a generator 21 and a fired steam generator 5.

[0032] The steam turbine 3 has three stages, a first turbine stage 11, a second turbine stage 13 and a third turbine stage 15, which are configured as a high-pressure stage, a medium-pressure stage and a low-pressure stage.

[0033] In the present exemplary embodiment in the FIGURE the steam generator 5 is a boiler fired by coal 27, to which combustion air 29 is supplied to maintain the coal-firing process.

[0034] A heating surface 37 is disposed in the area of the hot end of the steam generator 5 and an intermediate superheating heating surface 35 is disposed in a lower temperature area.

[0035] The heating surface 37 serves to heat a water supply 24 from a water supply tank 23 in the steam generator 5 such that operating steam can be supplied to the first turbine stage 11.

[0036] After partial expansion in the first turbine stage 1 the steam is subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com