Fresh flower bouquet system

a bouquet system and fresh flower technology, applied in the field of fresh flower bouquet systems, can solve the problems of high cost, difficult storage and storage of foam, and damage to floral foam with use, and achieve the effect of maximum shelf life and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

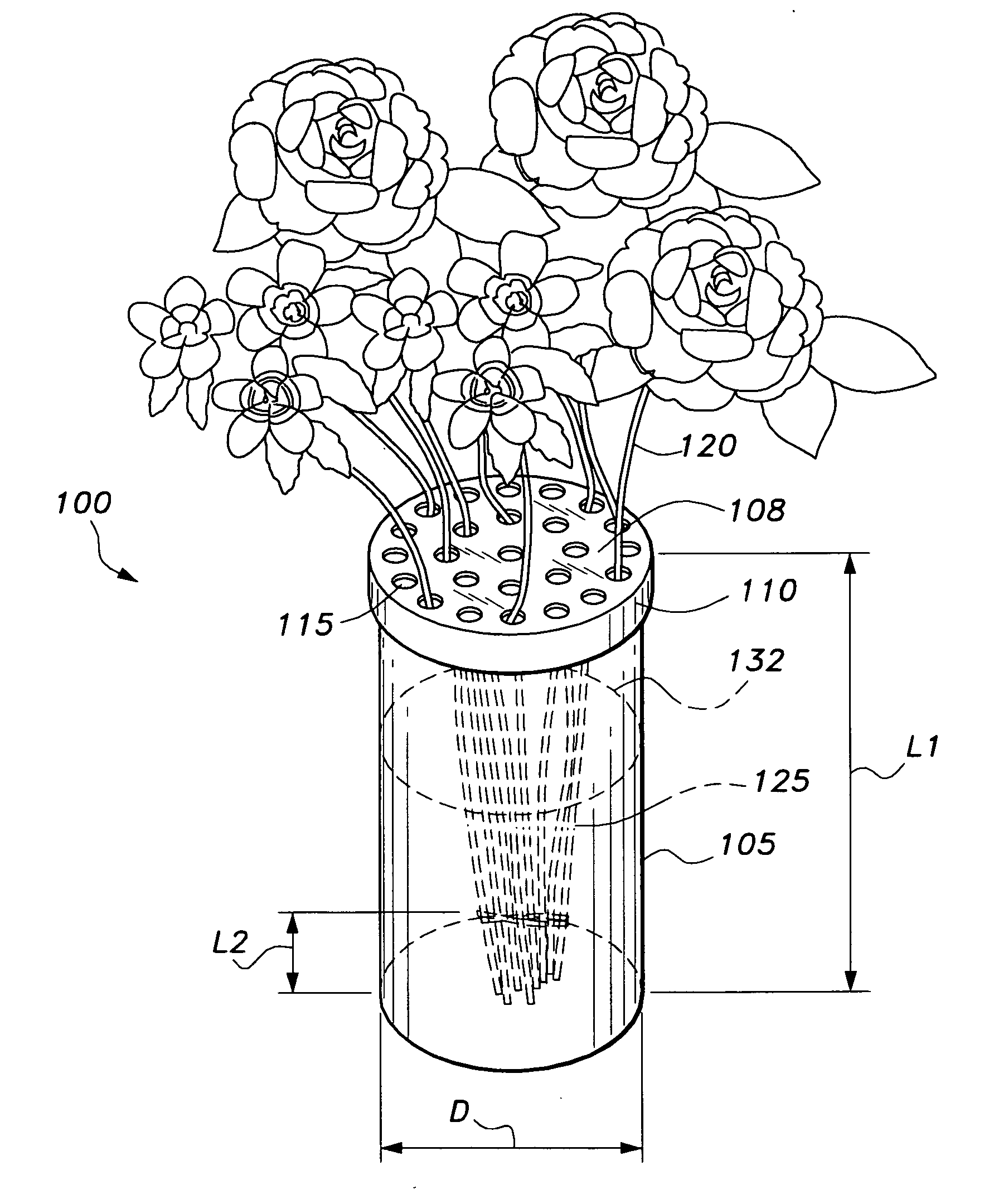

[0018] The present invention is a fresh flower bouquet system, designated generally as 100 in the drawings, that provides for cost-effective production of fresh floral bouquets, forming bouquets with symmetrical spacing of individual stems and maintaining the flowers in water and a cut flower hydrating solution without the use of floral foam.

[0019] As shown in FIG. 1, the system 100 of the present invention has a rigid cap 108 having a grid of symmetrically spaced through bores, i.e., holes 115, defined in the cap 108. The cap 108 may be made from plastic, or may be made from metal, but having the portion defining the grid formed without sharp edges that might cut the stems of the flowers during removal of the cap 108. It should be understood that the holes 115 have sufficient dimension to accommodate a typical cut stem from a flower. In addition, as shown in FIG. 4, the cap 108 has a cylindrical sidewall 110 defining internal threads 127, which are provided for threading the cap 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com