Muffler having fluid swirling vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

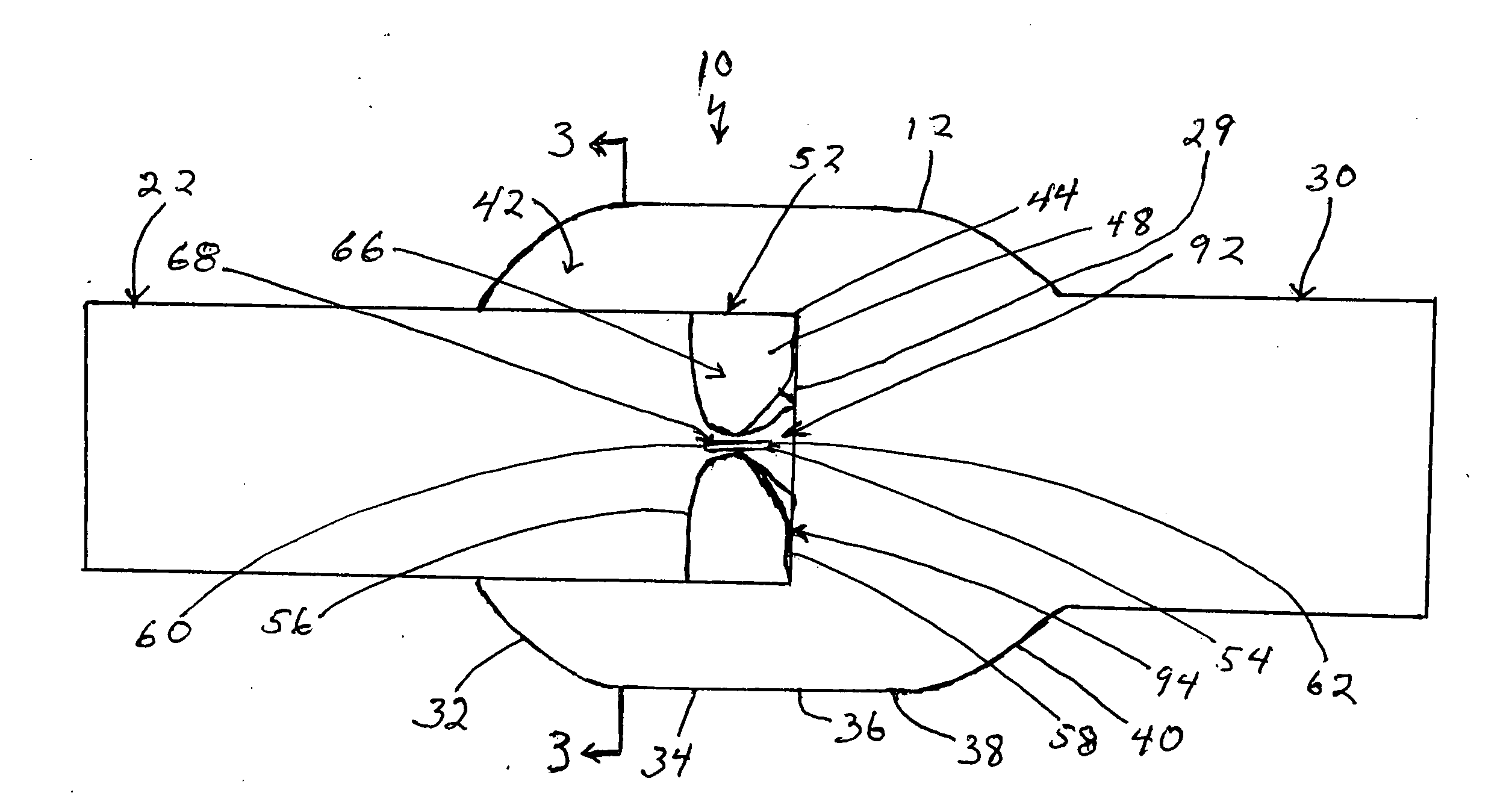

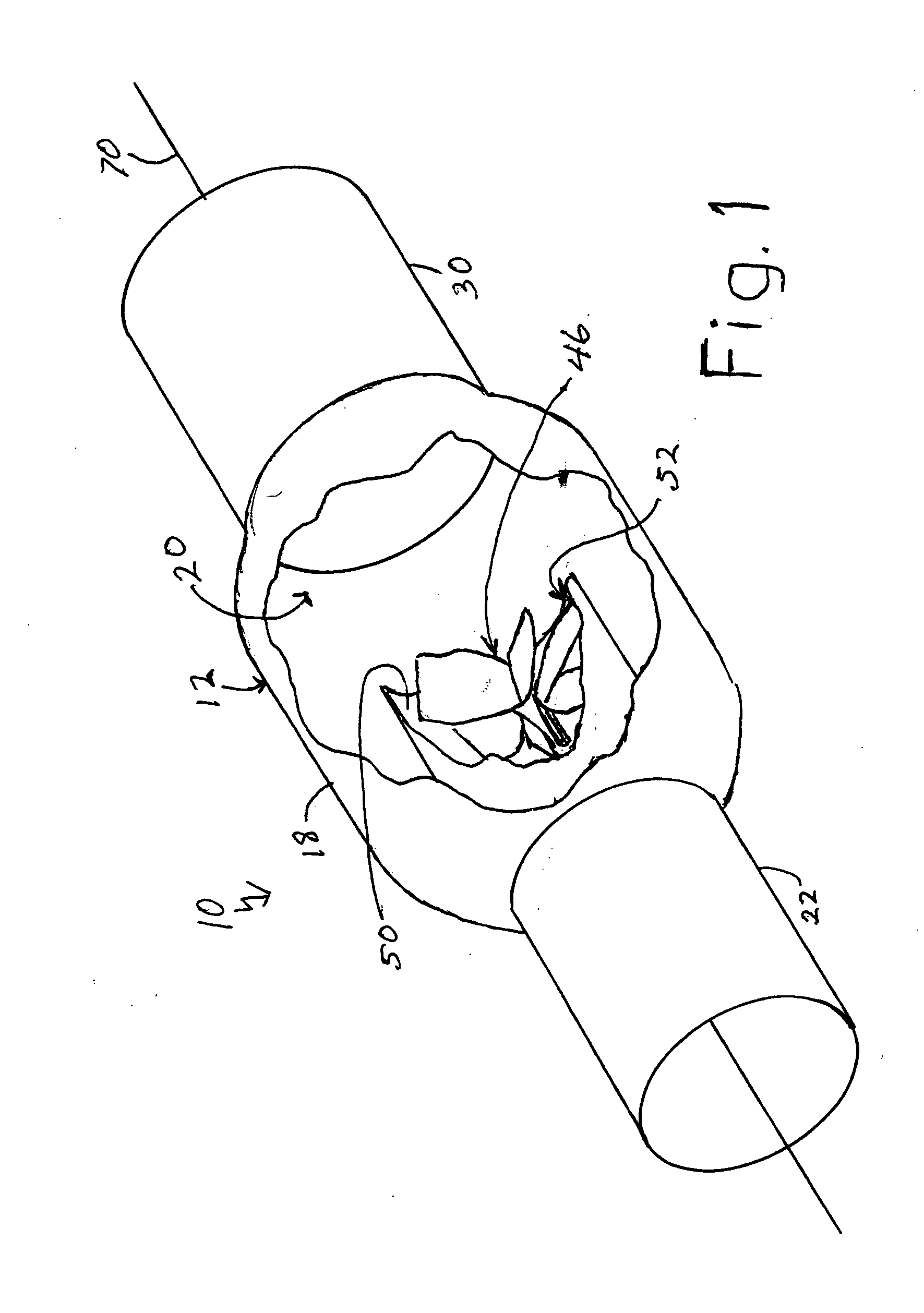

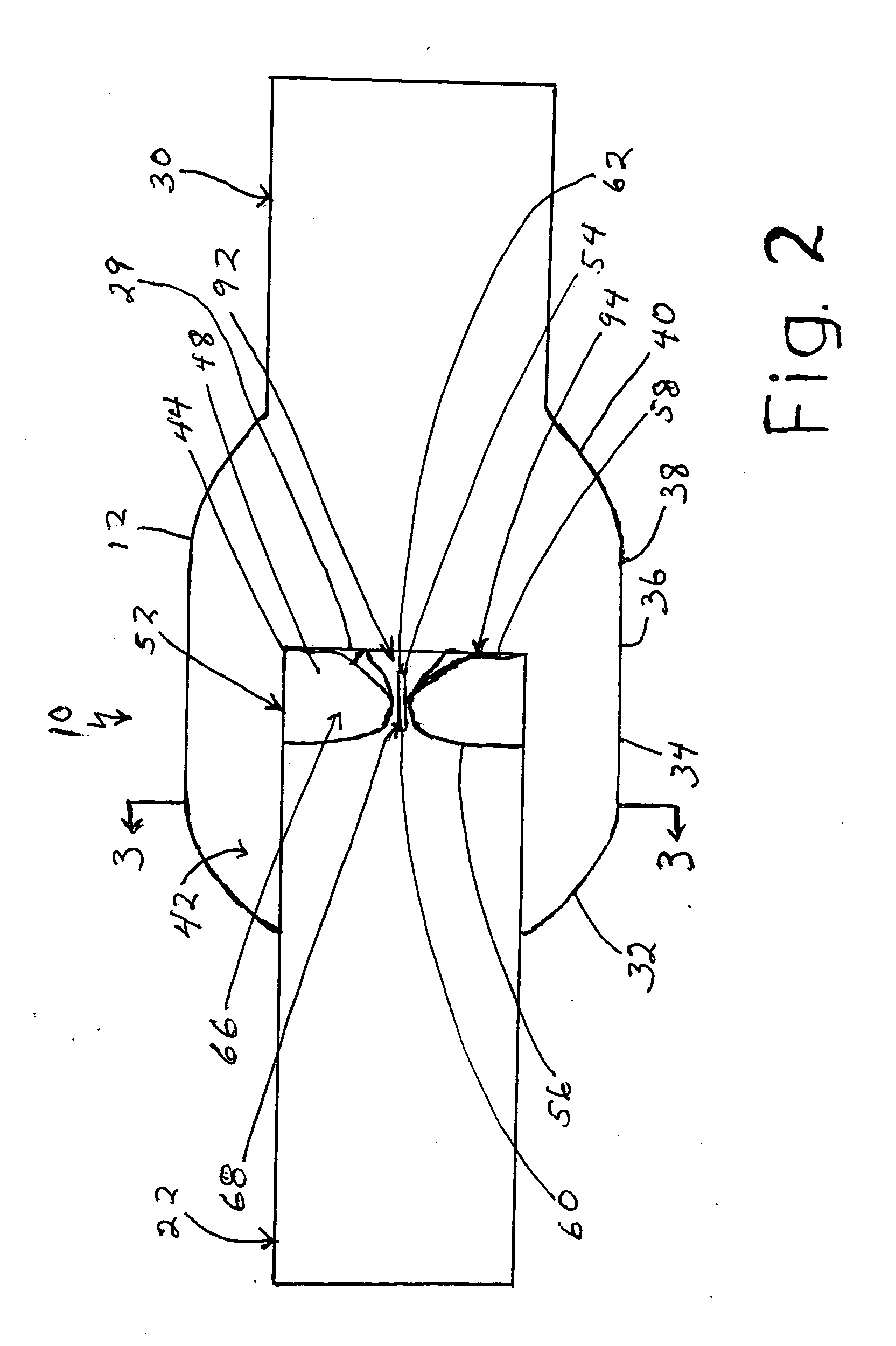

[0036] Referring to the drawings, the muffler of the present invention is generally designated by the numeral 10. The muffler 10 includes a casing 12. The casing 12 is hollow and includes an inlet port 14 and an outlet port 16 at opposite ends thereof. The casing 12 also includes a main body 18 defining an expansion chamber 20 in the casing 12 and located between the inlet port 14 and outlet port 16. An inlet duct 22 is connected to the inlet port 16 and has an inlet end 24 for connection to an exhaust pipe (not shown) to allow exhaust fluid 26 from an internal combustion engine (not shown) to enter the casing 12. The inlet duct 22 extends through the inlet port 14 and has an outlet (or discharge) end 28 for discharge of the exhaust fluid 26 into the expansion chamber 20 which has a larger cross-sectional area than the inlet duct 22 (and inlet port 14), as is typical for conventional mufflers. The casing 12 also includes an outlet duct 30 connected to the outlet port 16 for allowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com