Unit and a method for feeding tobacco in a machine for manufacturing tobacco products

a tobacco and machine technology, applied in tobacco, tobacco manufacture, tobacco treatment, etc., can solve the problems of unsuitable tobacco, product must be discarded, considerable loss of time and materials, etc., and achieve the effect of preventing the mingling of different types of tobacco and minimizing the impa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

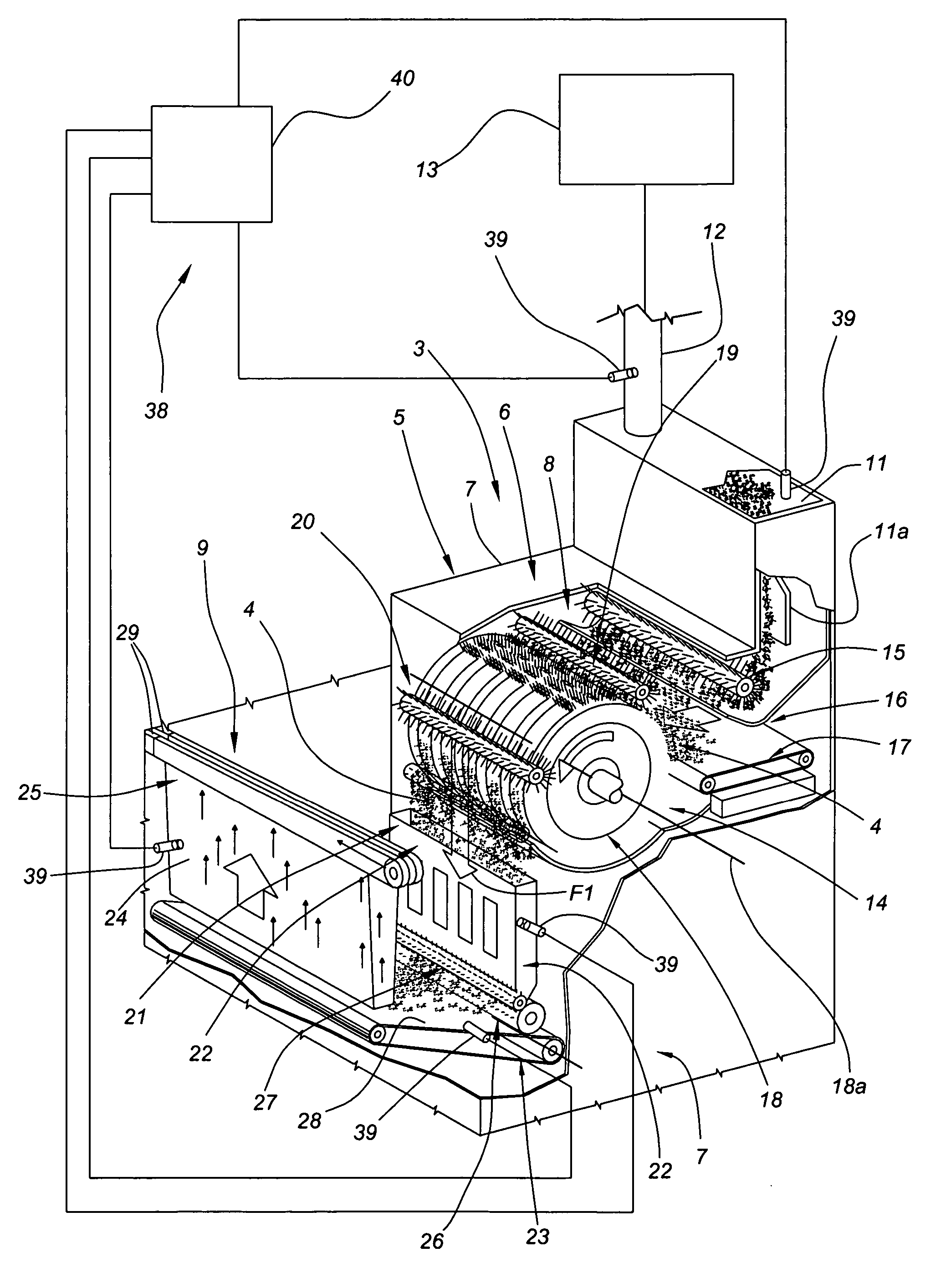

[0020] With reference to FIG. 1, numeral 1 denotes a machine, in its entirety, for manufacturing tobacco products 2 such as cigarettes, by way of example.

[0021] The machine, or cigarette maker 1, is equipped at the upstream end with a tobacco feed and transport section 3 by which a mass of shredded tobacco 4 is formed into a continuous flow of tobacco particles. The components of the feed and transport section 3 are housed in a vertically extending enclosure 5 delimited uppermost by a horizontal wall 6 and on either side by two vertical walls 7.

[0022] Shredded tobacco 4 is directed into at least one header chamber 11 surmounting the horizontal wall 6 and connected by way of at least one inlet duct 12 to a primary processing section denoted 13, shown schematically in FIG. 2. Leaf tobacco fed into this same section 13 is processed and conveyed by pneumatic means (not illustrated) along the duct 12 and into the chamber 11.

[0023] The section denoted 3, the inlet duct 12 and the outfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com