Handwheel-operated device

a technology of handwheel and chuck, which is applied in the direction of portable power-driven tools, applications, kitchen equipment, etc., can solve the problems of limited speed and/or torque that can be developed at the chuck, devices are therefore unsuitable for long-term use, and users who lack physical strength, and achieve the effect of accurate response of the speed of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

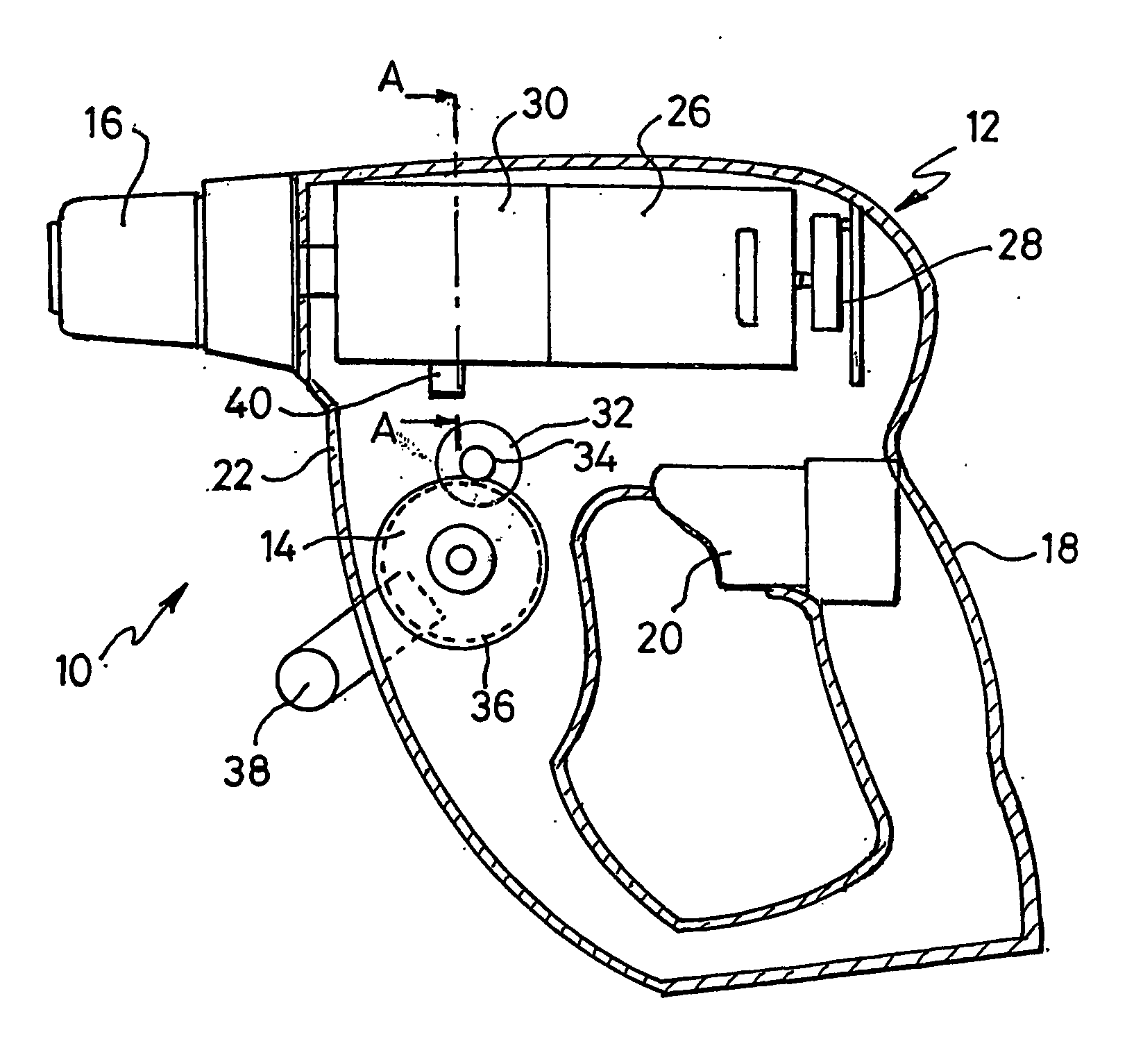

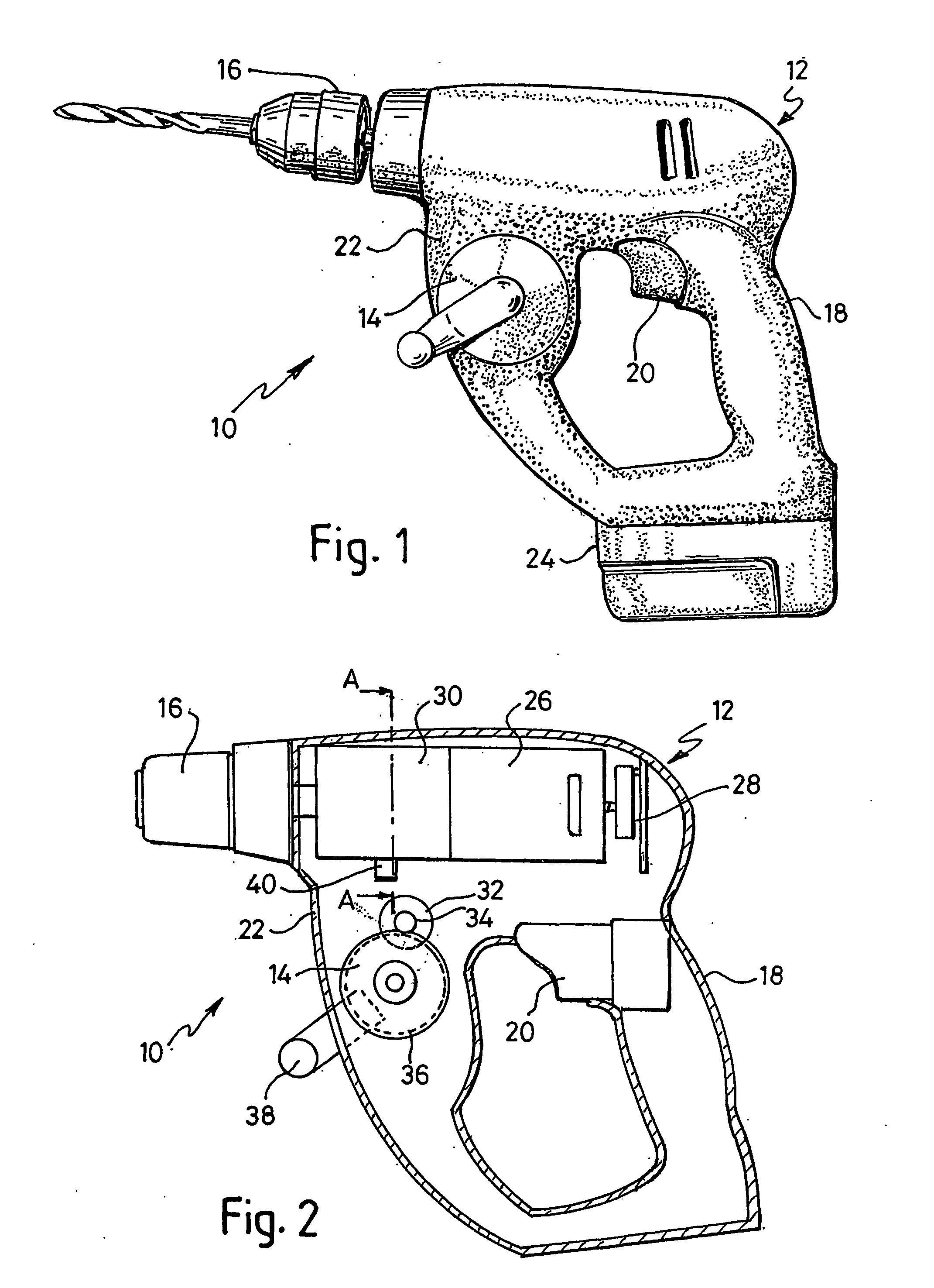

[0079] The cordless drill 10 of FIG. 1 comprises a body 12, a handwheel 14 and a chuck 16. Except for the handwheel, the drill 10 superficially resembles a conventional drill, with a pistol grip 18, trigger switch 20 located in the pistol grip, and forward housing portion 22 located in front of the trigger. The handwheel 14 is attached to the portion 22. A rechargeable battery 24 is removably attached to the base of the body.

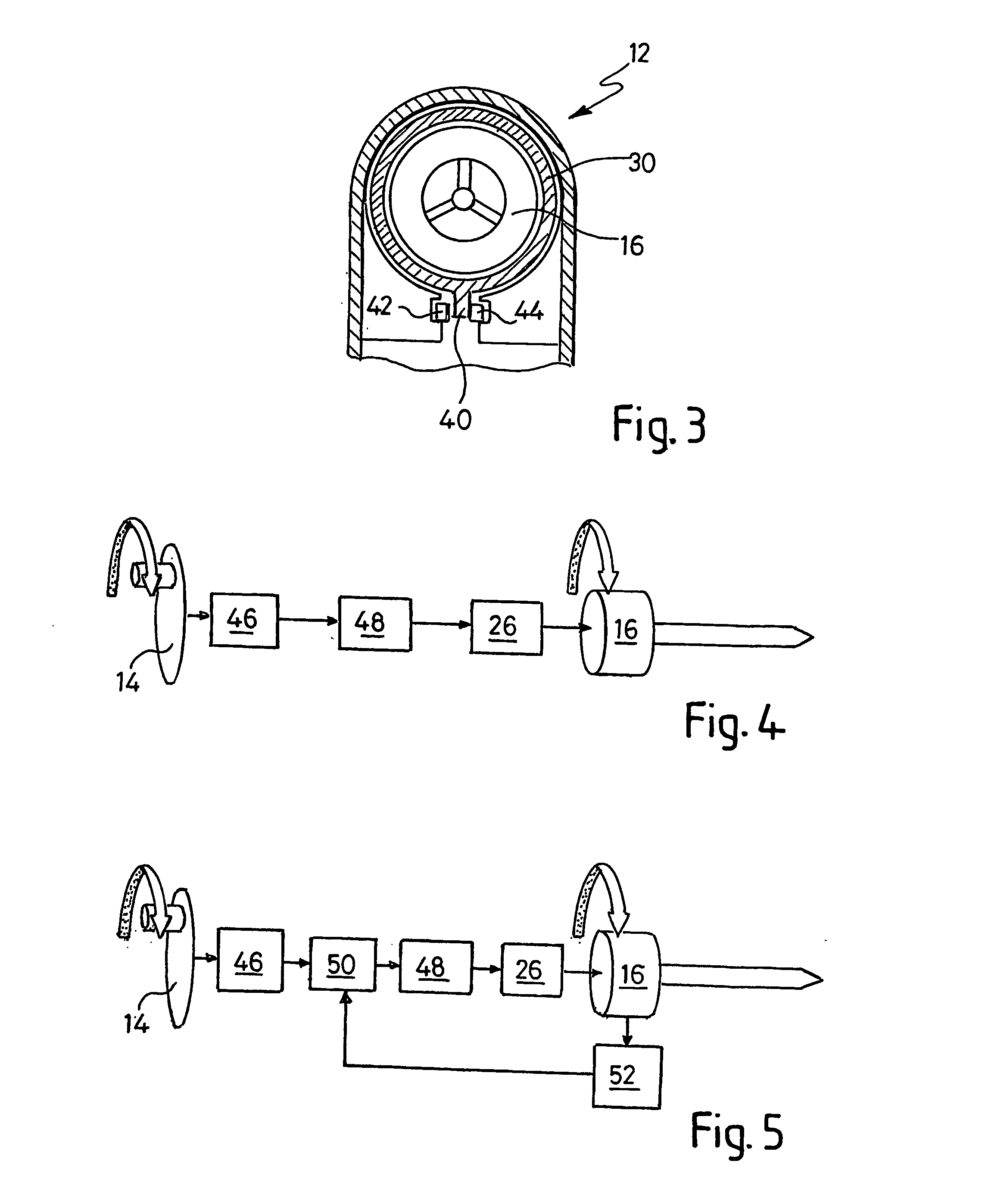

[0080] Turning to FIG. 2, from which the battery 24 has been omitted for the purpose of clarity, the body 12 contains a first motor 26, a first rotary encoder 28, a gearbox 30, a second motor 32, a second rotary encoder (not shown), and first and second gear wheels 34 and 36, respectively. The body 12 further contains first control means in the form of a programmed microprocessor (not shown). The first rotary encoder 28 is made up of a multipole magnet and three Hall effect detectors and is attached to a first end of the spindle of the first motor 26. The gearb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com