Method for manufacturing nano-array electrode and photoelectric conversion device using same

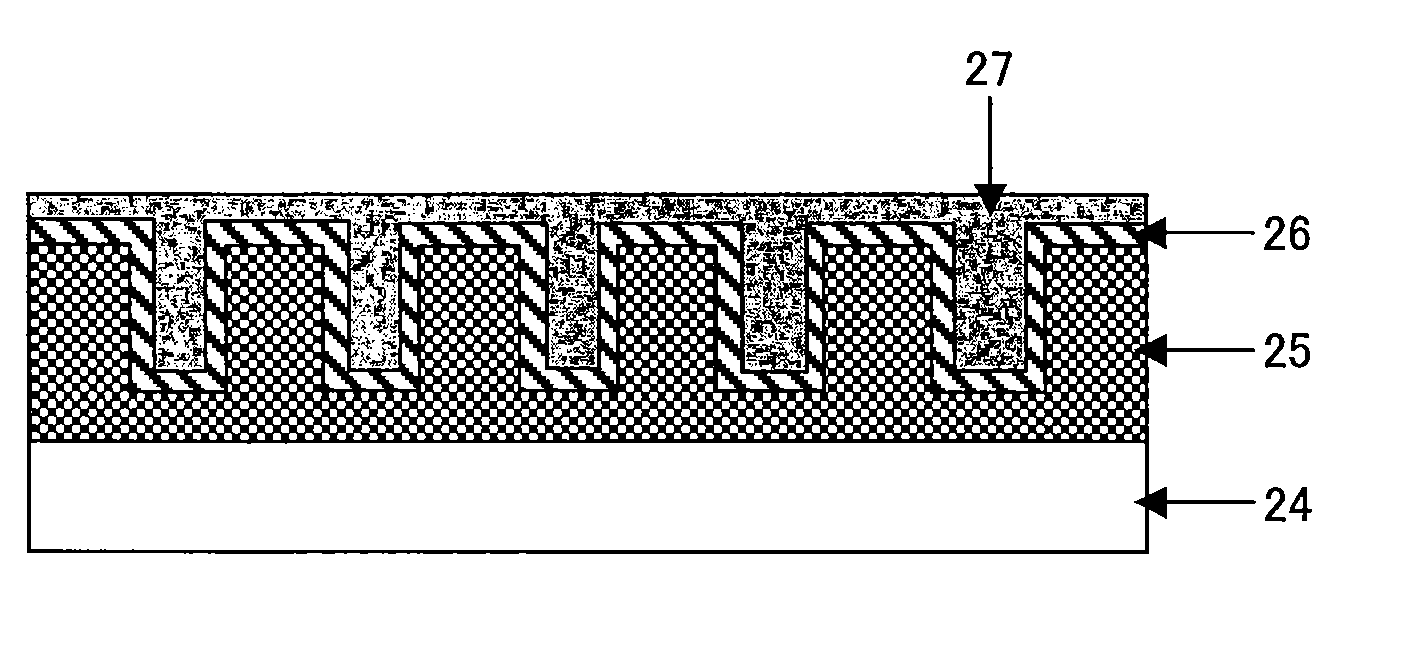

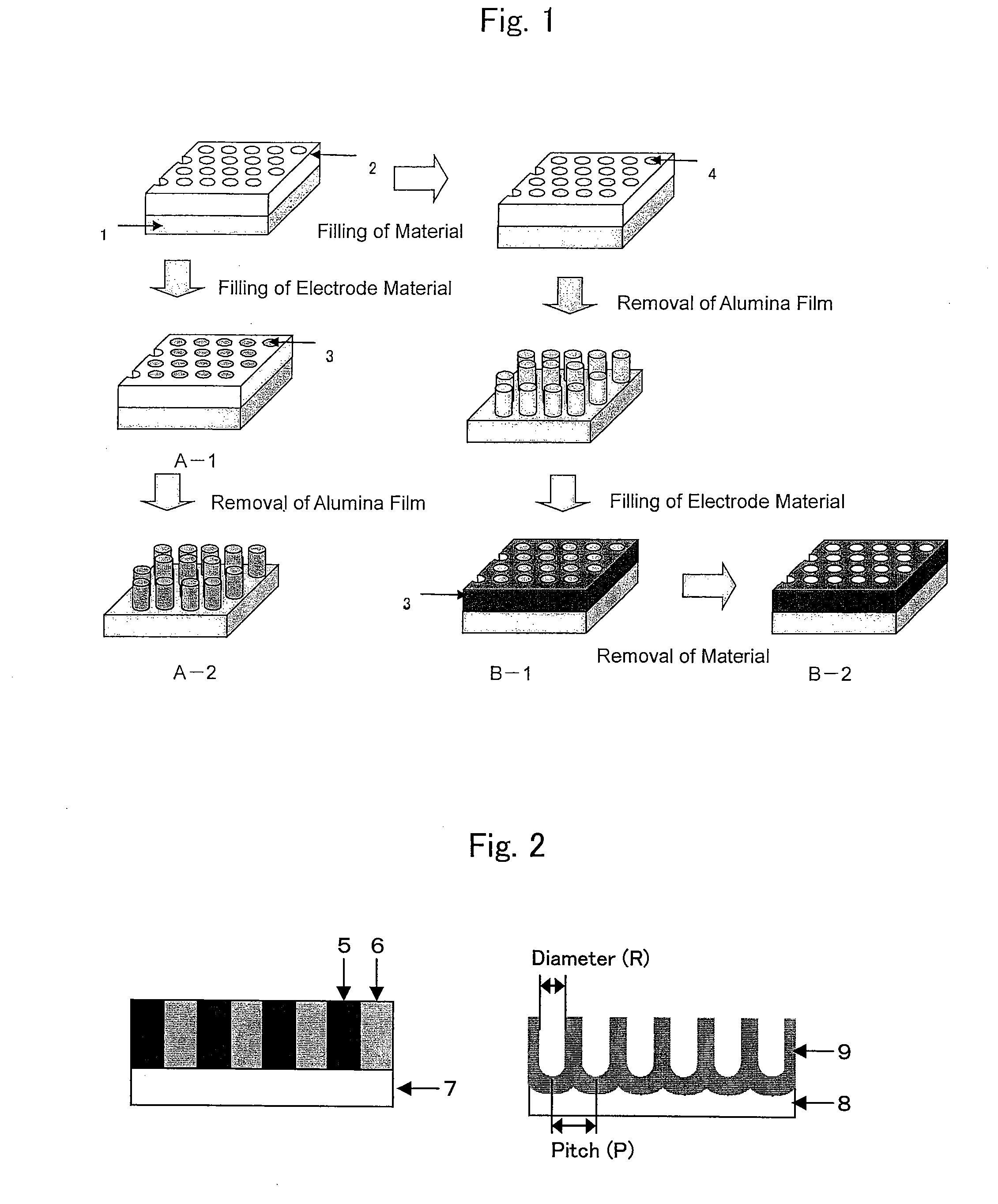

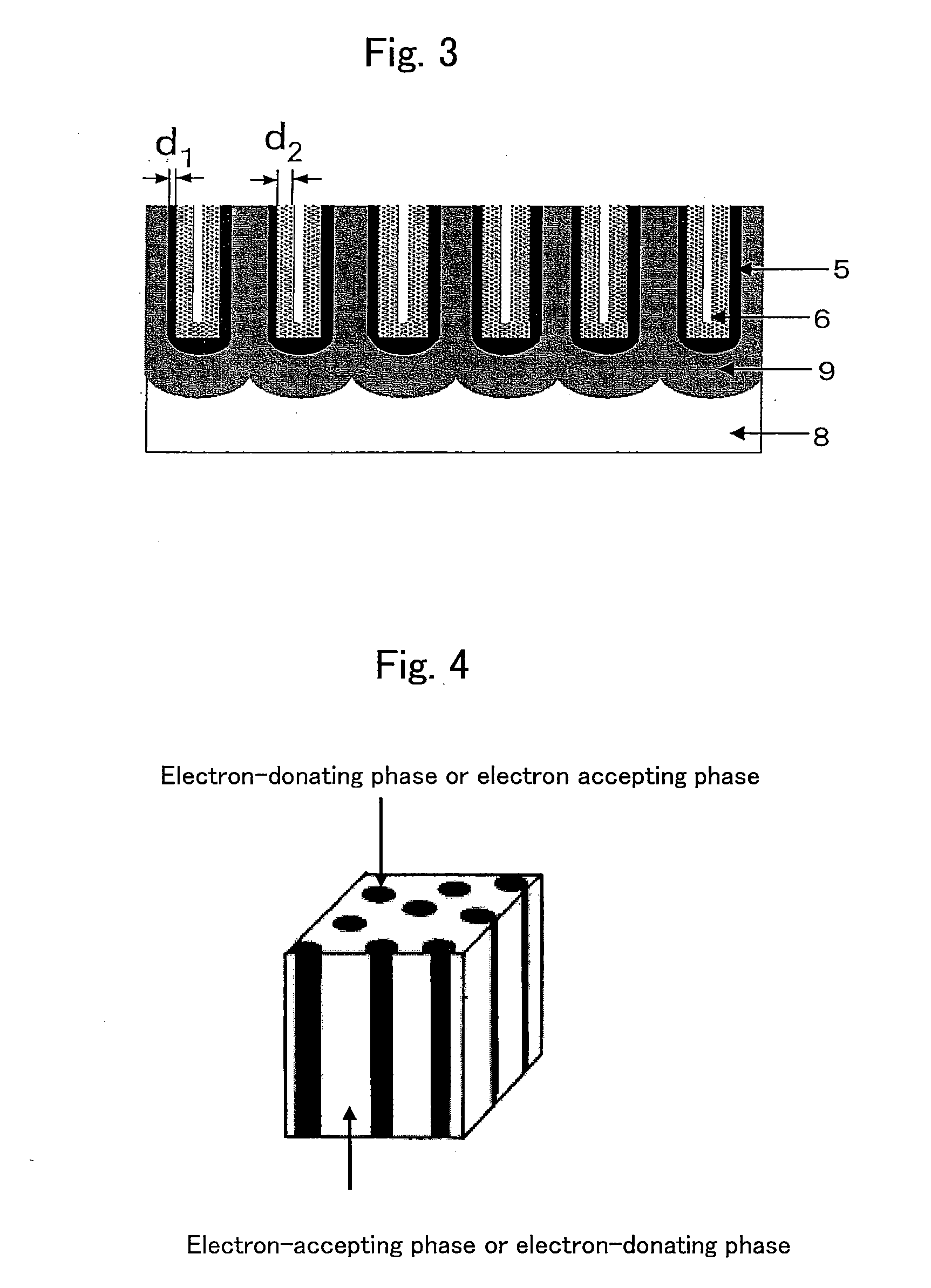

a photoelectric conversion device and nano-array electrode technology, applied in the field of nano-array electrodes, can solve the problems of affecting the enhancement of productivity, difficult to accurately control the structure of particles, and deactivation of elementary excitation states, and achieve the effects of enhancing the efficiency of organic film solar cells, effective charge separation, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[Manufacture of an Anodic-Oxide Porous Alumina Film]

[0212] An aluminum substrate (purity: 99.99%, manufactured by TOYO ALUMINIUM K.K.) was subjected to constant-current electrolysis at a temperature of 70° C. in a sulfuric acid-phosphoric acid mixed solution (85% 330 mL phosphoric acid, 75 mL concentrated sulfuric acid, 15 mL ethylene glycol, and 80 mL water) for 5 minutes by applying a current of 250 mA / cm2 to the aluminum substrate used as an anode and a black carbon used as a cathode and then washed with water and dried. An anodic oxidization was conducted at a temperature of 16° C. in an aqueous solution containing 0.5 mol / L oxalic acid for 5 hours by applying a voltage of 40 V to the aluminum substrate used as an anode and a black carbon used as a cathode. Thereafter, the aluminum substrate was dipped into a chromic acid-phosphoric acid mixed solution (6 g chromic oxide, 20 g phosphoric acid, and 300 g water) at a temperature of 50° C. for 12 hours and then washed with water a...

example 2

[Manufacture of an Anodic-Oxide Porous Alumina Film]

[0216] An aluminum substrate (purity: 99.99%, manufactured by TOYO ALUMINIUM K.K.) was subjected to constant-current electrolysis at a temperature of 70° C. in a sulfuric acid-phosphoric acid mixed solution (85% 330 mL phosphoric acid, 75 mL concentrated sulfuric acid, 15 mL ethylene glycol, and 80 mL water) for 5 minutes by applying a current of 250 mA / cm2 to the aluminum substrate used as an anode and a black carbon used as a cathode and then washed with water and dried. An anodic oxidization was conducted at a temperature of 16° C. in an aqueous solution containing 0.5 mol / L oxalic acid for 5 hours by applying a voltage of 40 V to the aluminum substrate used as an anode and a black carbon used as a cathode. Thereafter, the aluminum substrate was dipped into a chromic acid-phosphoric acid mixed solution (6 g chromic oxide, 20 g phosphoric acid, and 300 g water) at a temperature of 50° C. for 12 hours and then washed with water a...

example 3

[Manufacture of an Anodic-Oxide Porous Alumina Film]

[0220] An aluminum substrate (purity: 99.99%, manufactured by TOYO ALUMINIUM K.K.) was subjected to constant-current electrolysis at a temperature of 70° C. in a sulfuric acid-phosphoric acid mixed solution (85% 330 mL phosphoric acid, 75 mL concentrated sulfuric acid, 15 mL ethylene glycol, and 80 mL water) for 5 minutes by applying a current of 250 mA / cm2 to the aluminum substrate used as an anode and a black carbon used as a cathode and then washed with water and dried. An anodic oxidization was conducted at a temperature of 16° C. in an aqueous solution containing 0.3 mol / L sulfuric acid for 8 hours by applying a voltage of 25 V to the aluminum substrate used as an anode and a black carbon used as a cathode. Thereafter, the aluminum substrate was dipped into a chromic acid-phosphoric acid mixed solution (6 g chromic oxide, 20 g phosphoric acid, and 300 g water) at a temperature of 50° C. for 12 hours and then washed with water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com