Perforated armor plates

a technology of armor plates and perforations, applied in the field of multi-layer ballistic armor, can solve the problem of reducing the residual penetration capability of basic armor by a substantial amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

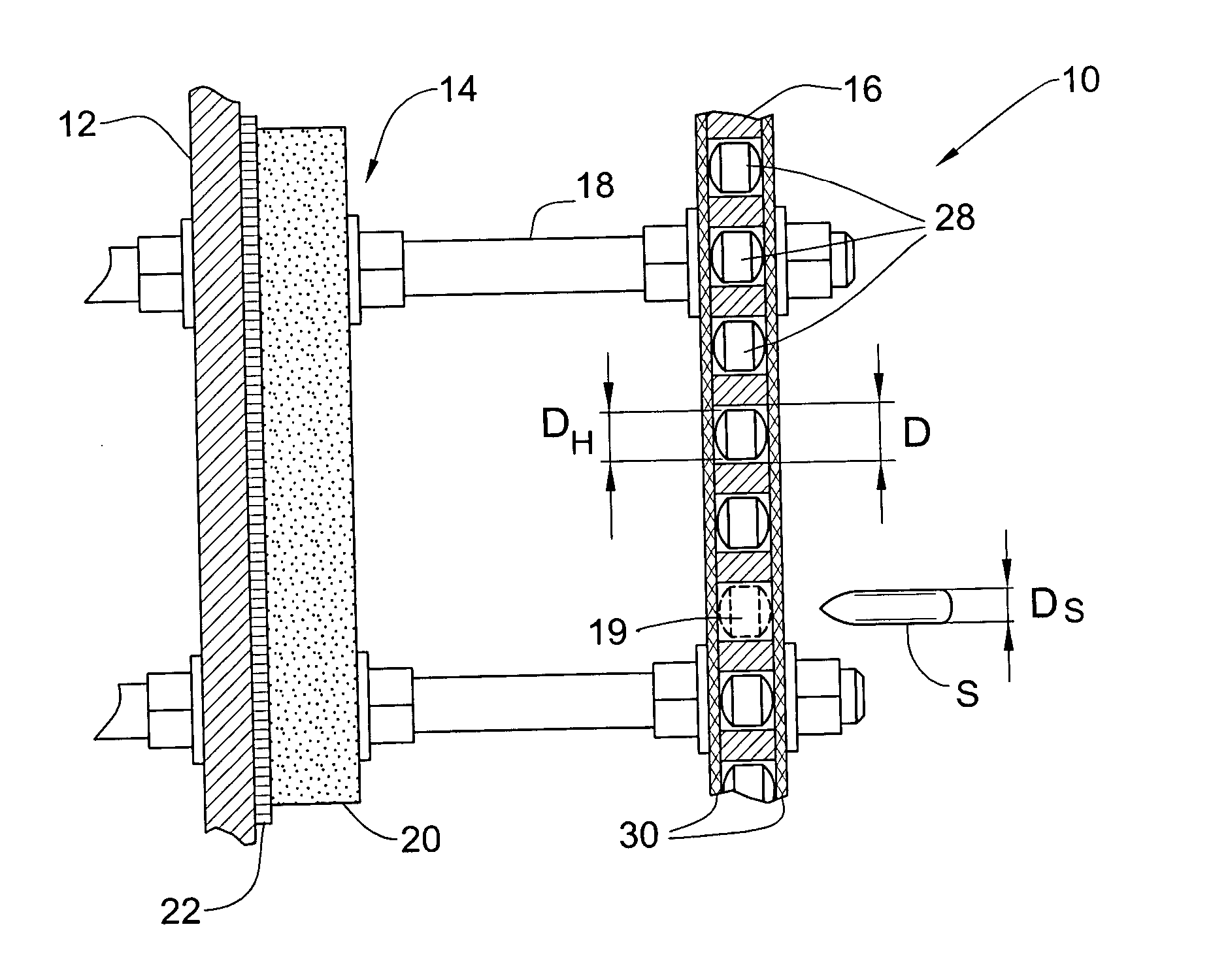

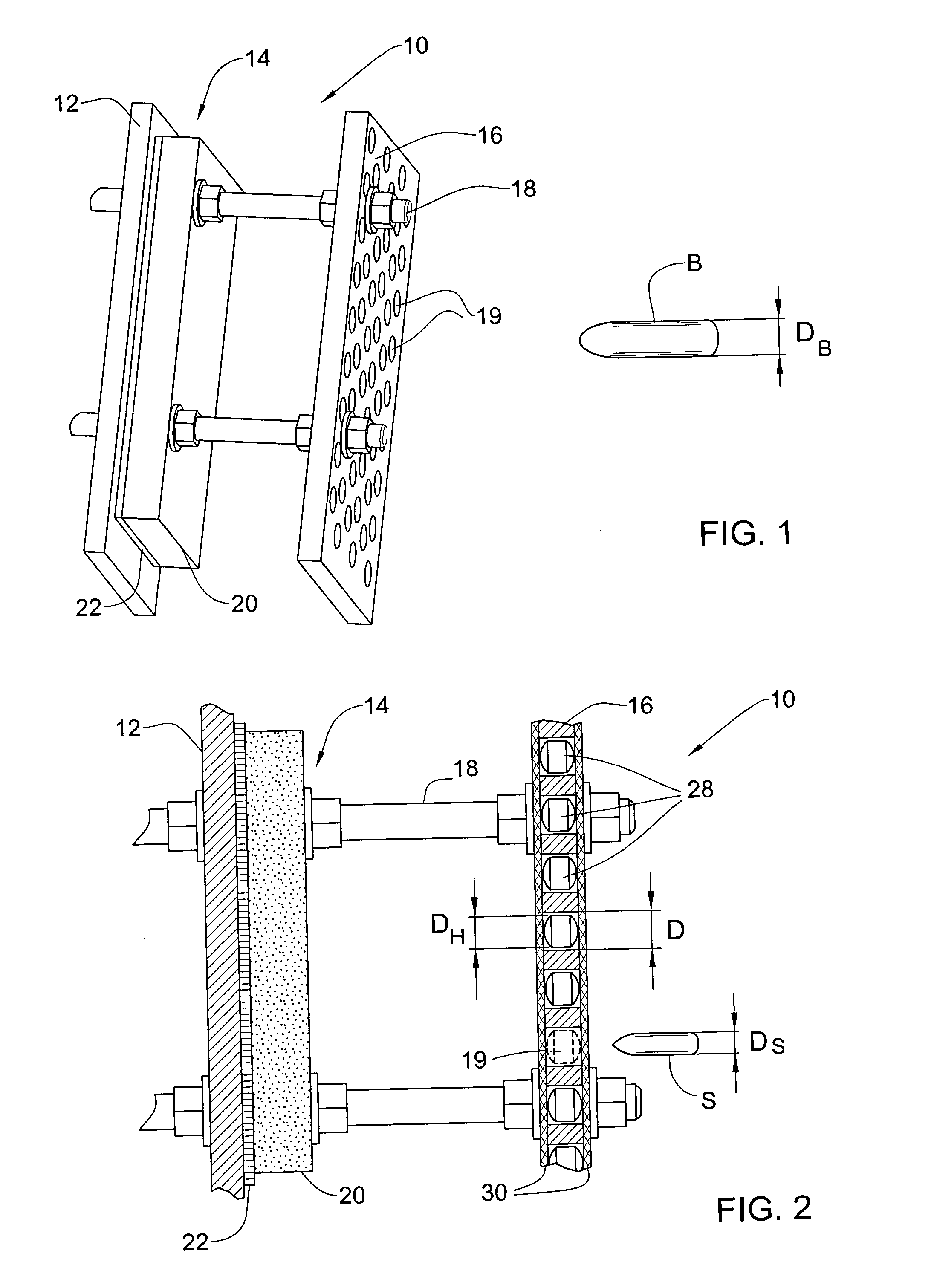

[0032] An armor system 10 schematically shown in FIGS. 1 and 2 is an example of ballistic armor of the present invention designed for ballistic protection of a basic structure, e.g. side wall 12 of a vehicle, against two kinds of ballistic threats, for example, large caliber bullets B and smaller caliber bullets S.

[0033] The armor 10 comprises a main armor plate 14 and an auxiliary armor plate 16 located in front of the main armor plate 14. The plates 14 and 16 are attached to the side wall 12 by attachment means such as bolts 18 as shown in FIG. 1. Alternatively, the main armor plate 14 may be attached to the side wall 12 by one attachment means, and the auxiliary plate 16 may be attached to the main plate 14 or to the side wall by another attachment means. The attachment means are designed to keep the plates at a predetermined fixed distance (stand-off) from each other.

[0034] The main armor plate 14 is designed to stop alone, or together with the side wall 12 but without the aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com