Fiberglass pool edge coping system

a technology of fiberglass pool and coping system, which is applied in the direction of gymnasium, construction, buildings, etc., can solve the problems of non-rigid shell structure generally involves a degree of trial and error, the top edge of the pool liner is out of true relative to typical construction tolerance, and the pool is difficult to install with precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

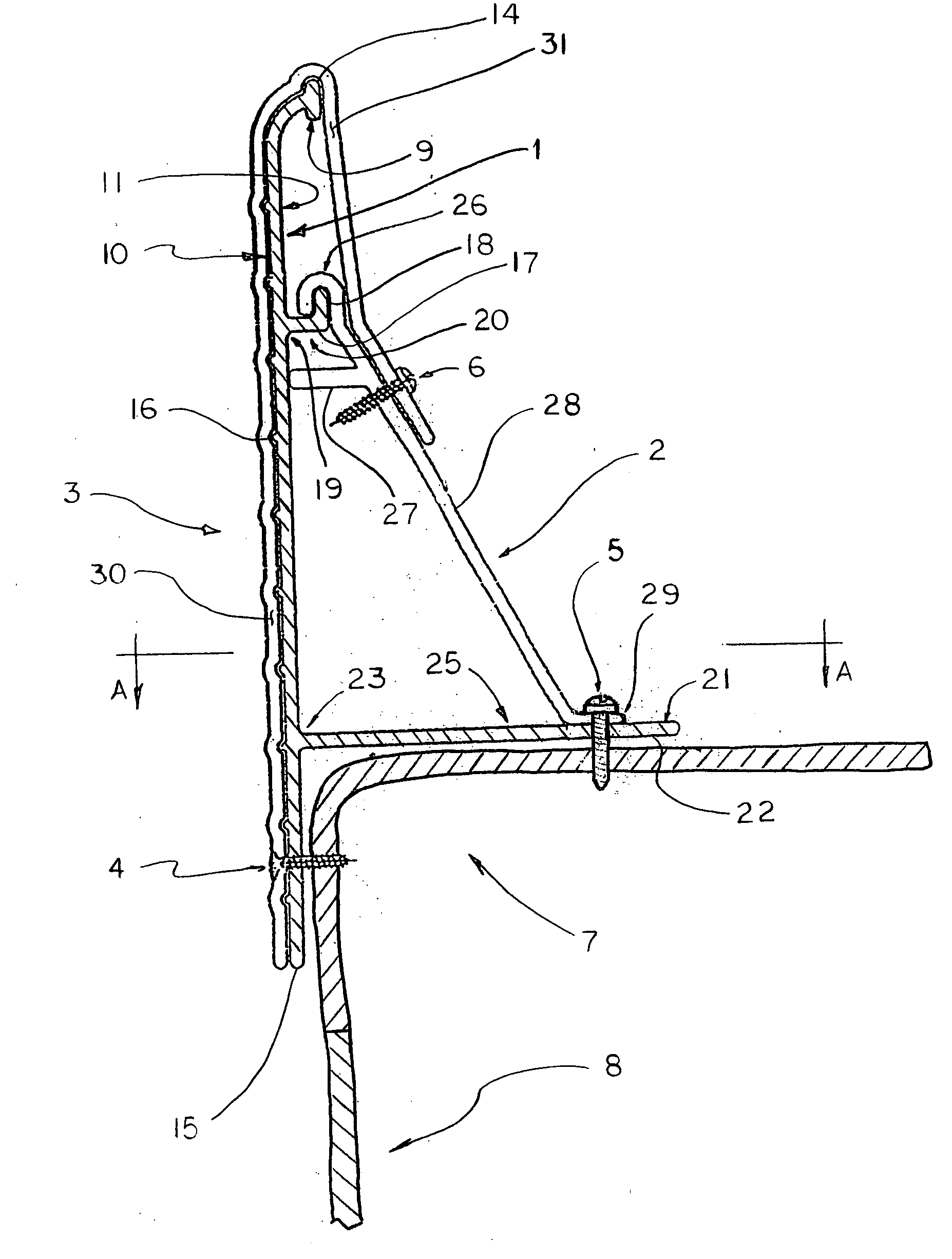

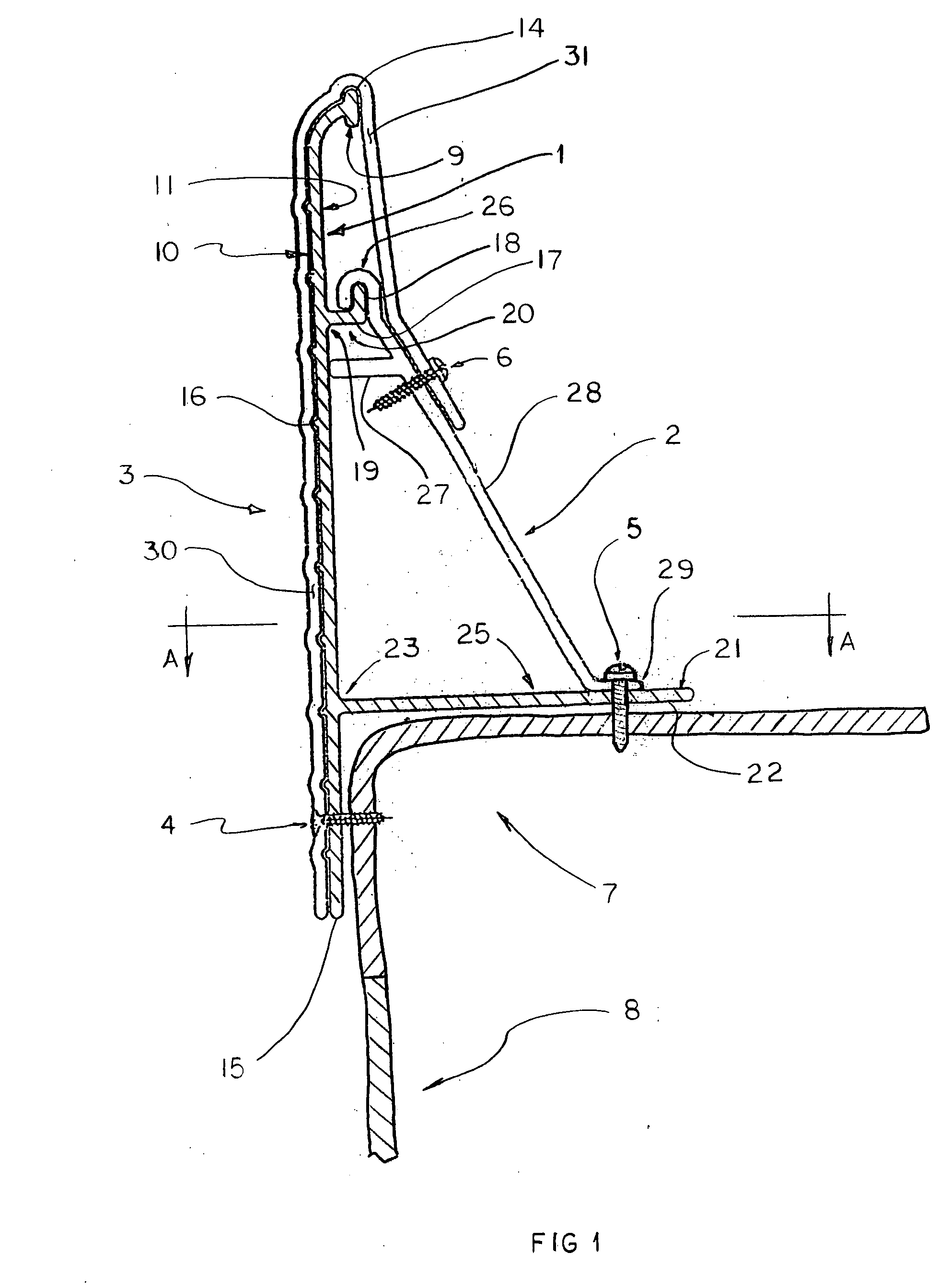

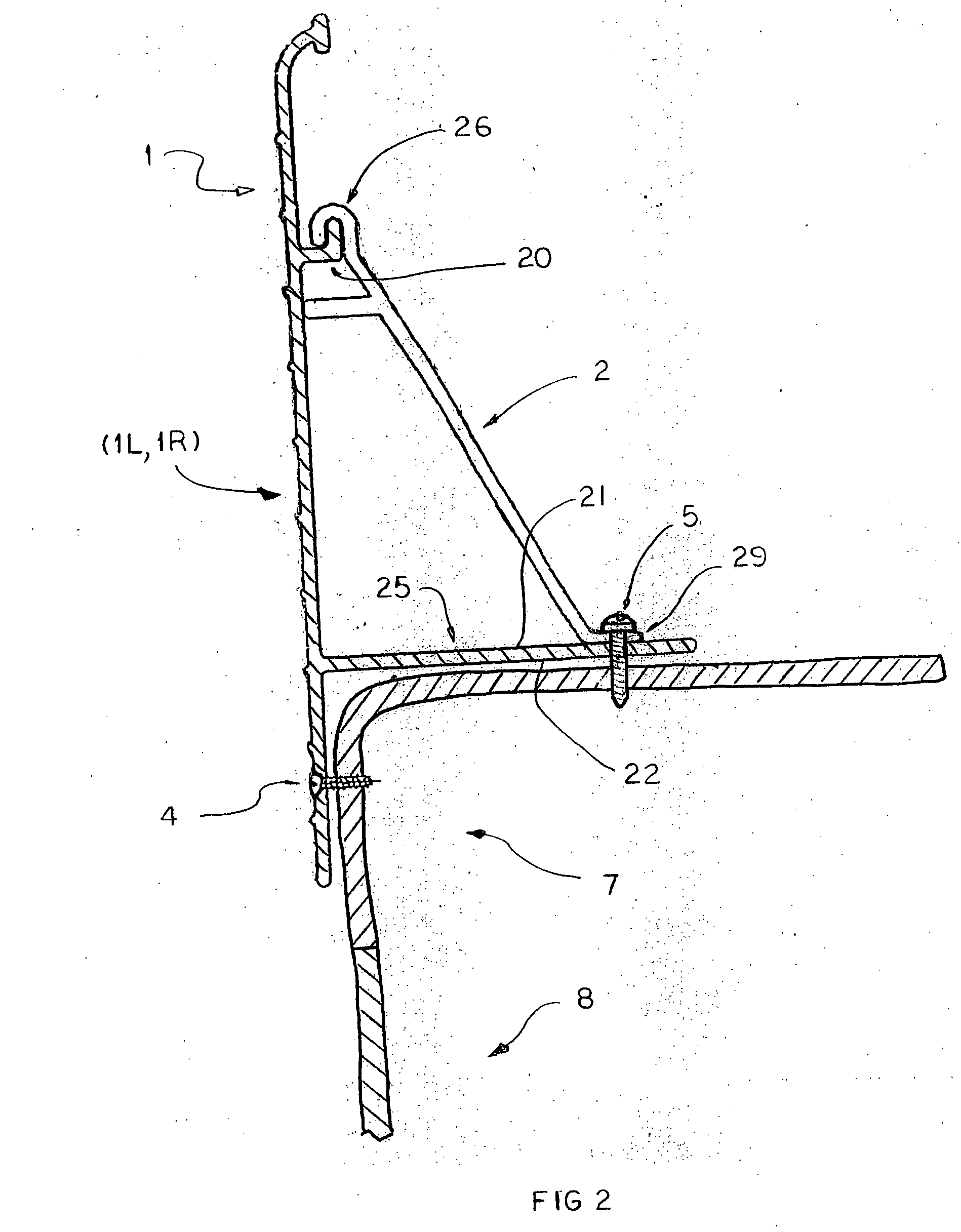

first embodiment

[0042] The installation process of the first embodiment continues, placing additional edging bands, intermediate anchors, joint anchors and joint clips, finishing with a final edging band (not shown) being cut to length and fit to the left end of the first edging band 1L (not shown) in a final butt joint (not shown), until the entire top corner of the pool is edged with the edging band. This creates a continuous edging band (not shown) around the entire perimeter of the pool.

[0043] Once the continuous edging band is ready, additional known preparation of a concrete placement area is completed. Said concrete placement area comprises a prepared surface beginning at said continuous ending band and projecting away from back side 11 of all edging bands comprising said continuous band to a known limit. Concrete is then placed in said concrete placement area, utilizing said continuous edging band as a retaining wall (a concrete form) to prevent a flow of wet concrete into the pool, and sim...

third embodiment

[0046] In a third embodiment, front side 10 may be decorated with paint or a pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com