Tensioning anchor suitable for blind-hole tendon anchoring and tendon repair

a technology of tendon anchoring and tensioning anchors, which is applied in the direction of building reinforcements, construction, building material handling, etc., can solve the problems of preventing the erection of just described cables, affecting the construction of pillars, and unable to meet the requirements of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

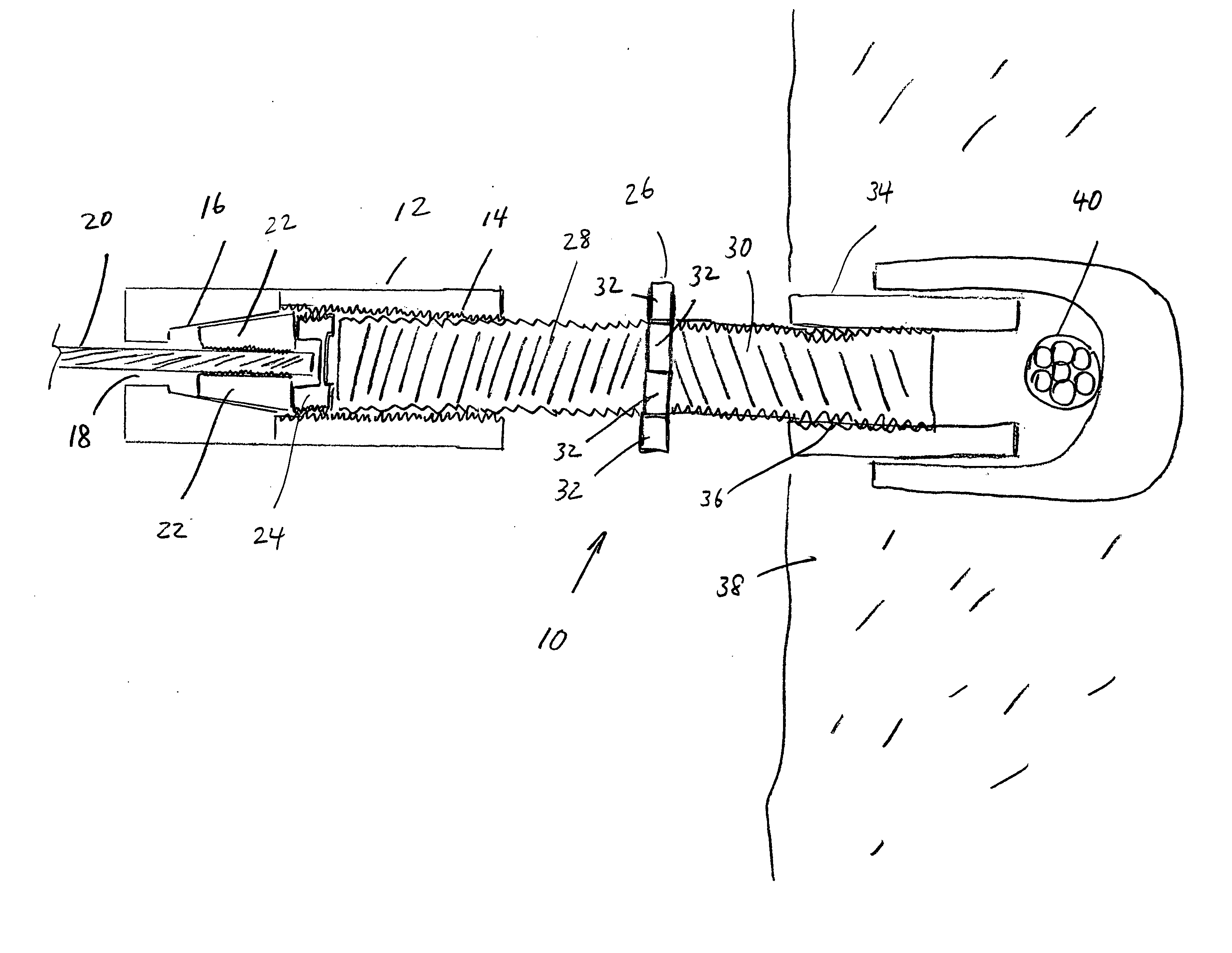

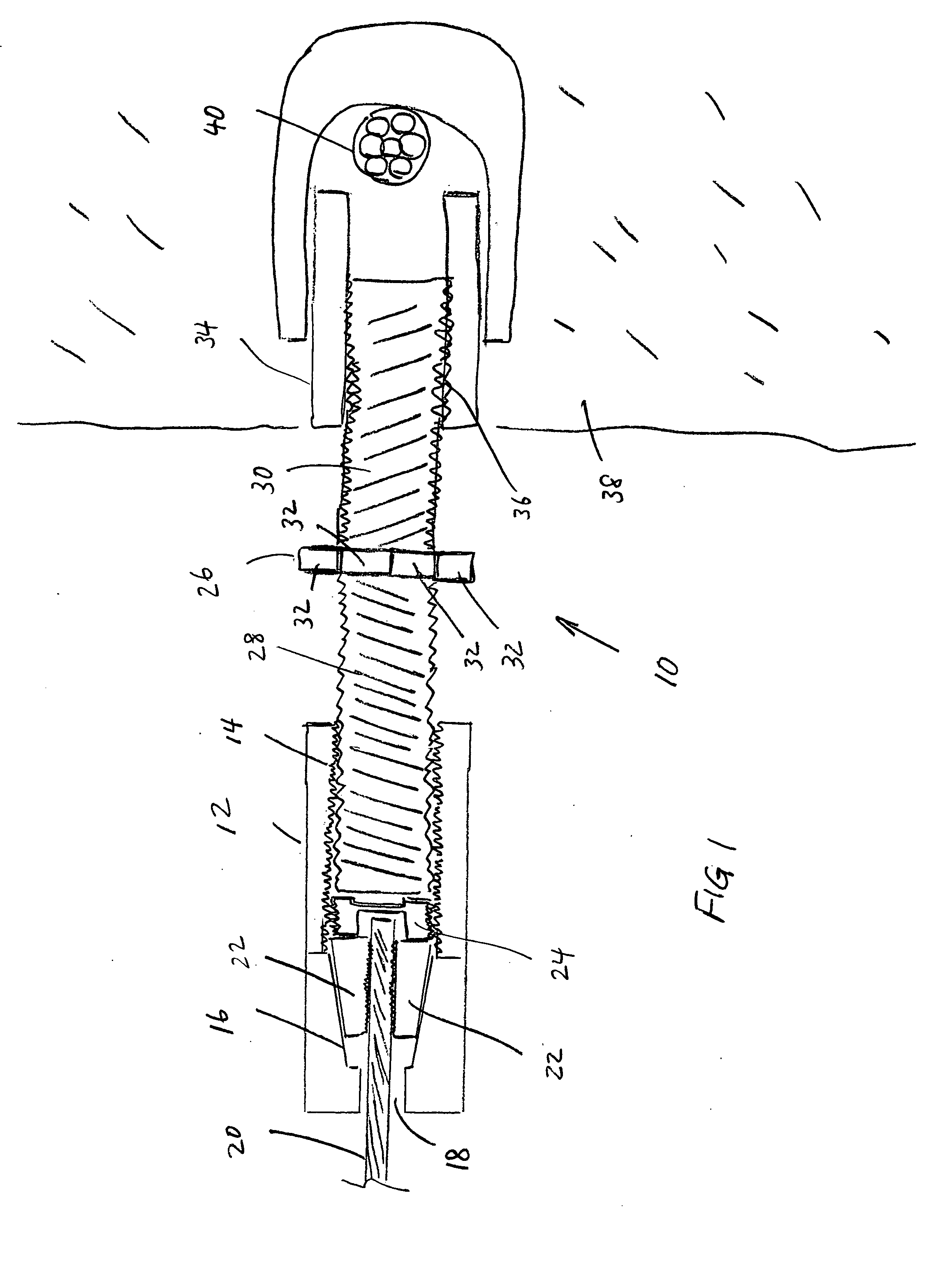

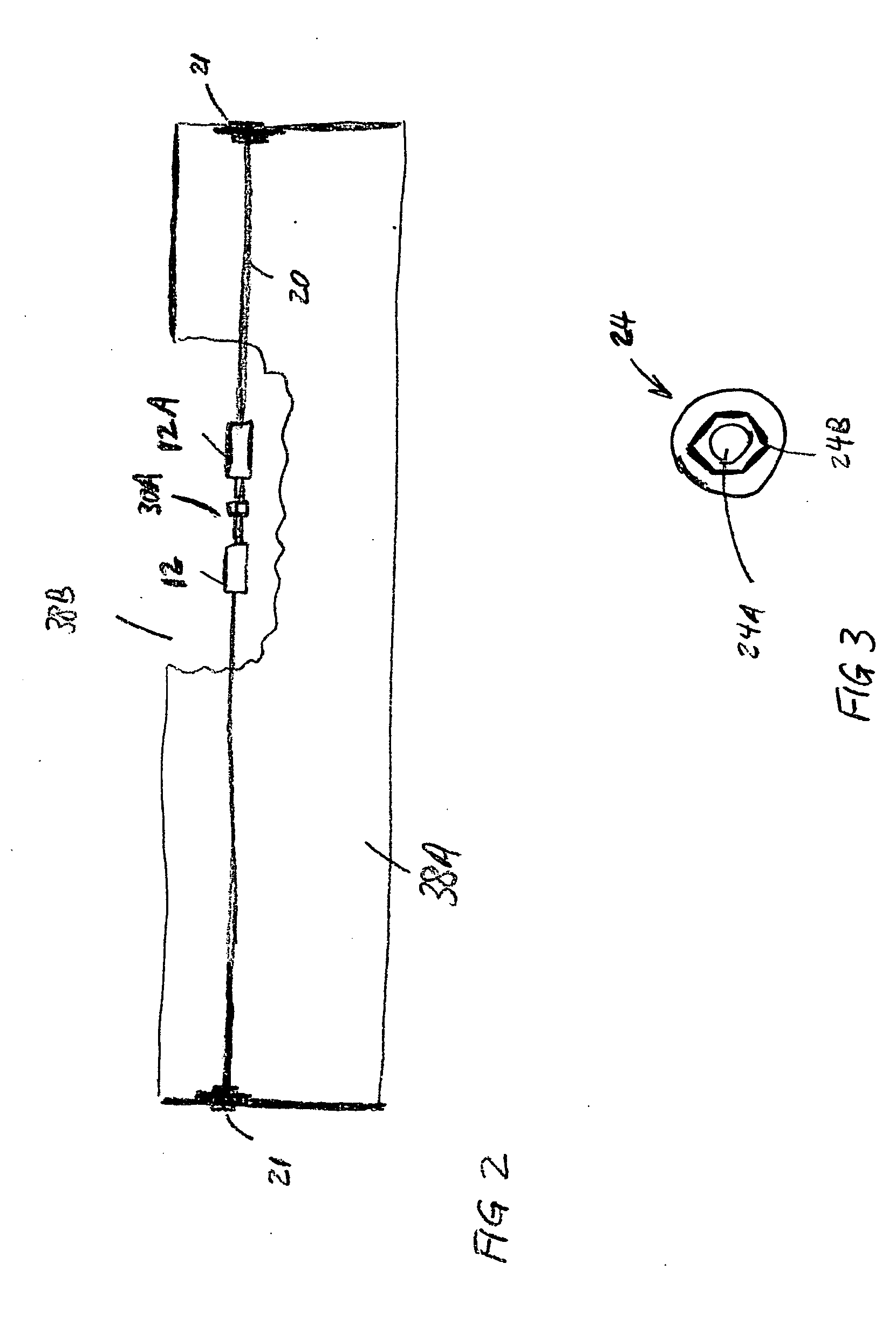

[0025]FIG. 1 shows one embodiment of a tendon anchor system 10 that can be used to anchor a tendon 20 within a blind opening in an anchoring structure, that is, where an opposite side of the anchoring structure is inaccessible. The tendon 20 is typically made from steel or other high strength material. The tendon anchor system 10 includes an anchor body 12, which may be formed from steel or other high strength material.

[0026] The anchor body 12 includes a device to retain the tendon 20 within, such that under tension, the tendon 20 is restrained from longitudinal movement out of the anchor body 12. The device in the present embodiment can include a generally tapered wedge receiving bore 16, and a wedge 22 adapted to be applied to the exterior of the tendon 16 and to fit within the receiving bore 16. The wedge 22 may include a threaded interior surface or similar arrangement of gripping elements to grip the outer surface of the tendon 20, and may be formed from a plurality of wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com