Power transmission apparatus

a technology of transmission apparatus and transmission shaft, which is applied in the direction of gear lubrication/cooling, hoisting equipment, gearing elements, etc., can solve the problems of reducing the durability of bearings, and often not providing electromagnetically controlled clutches to reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

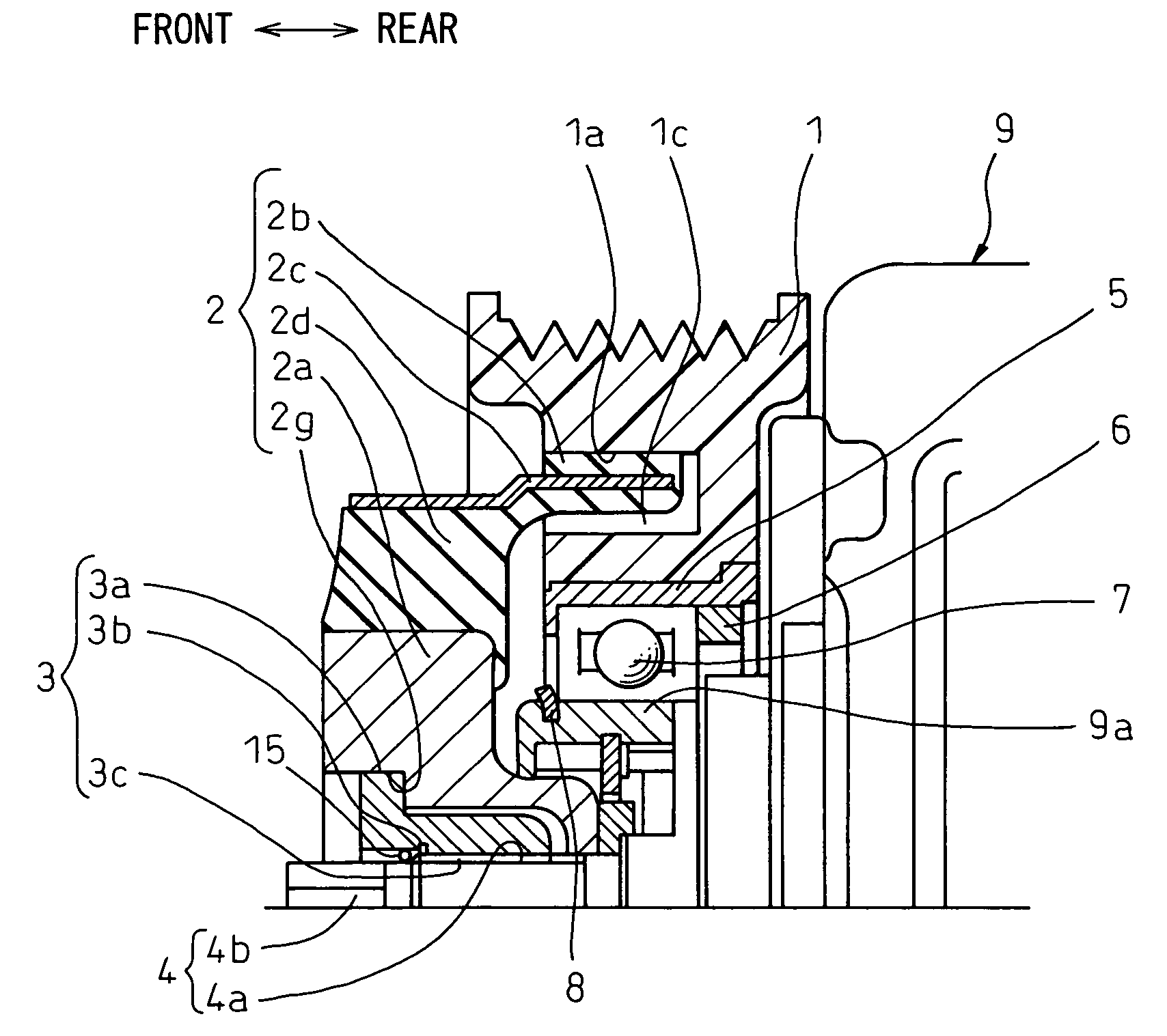

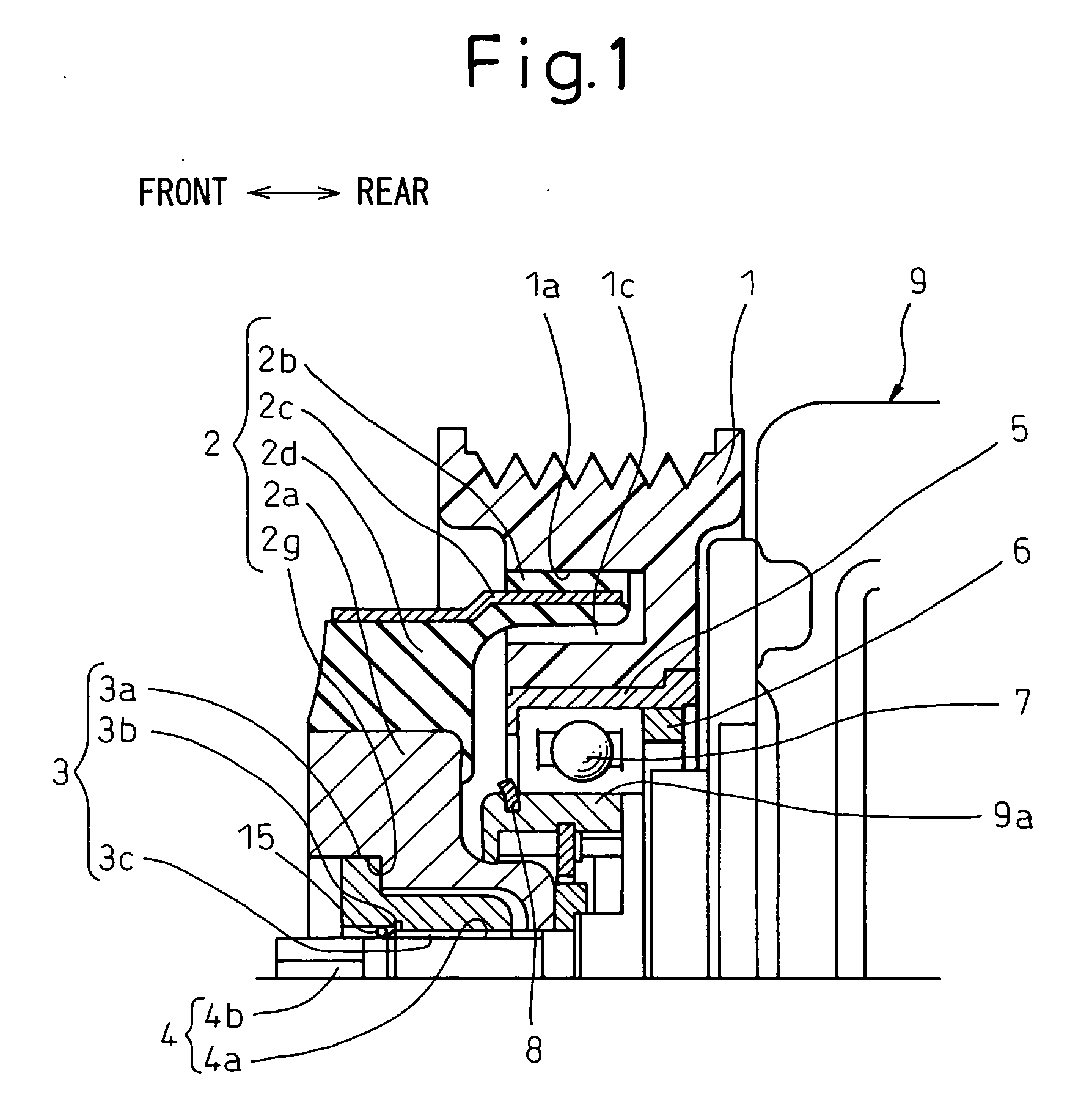

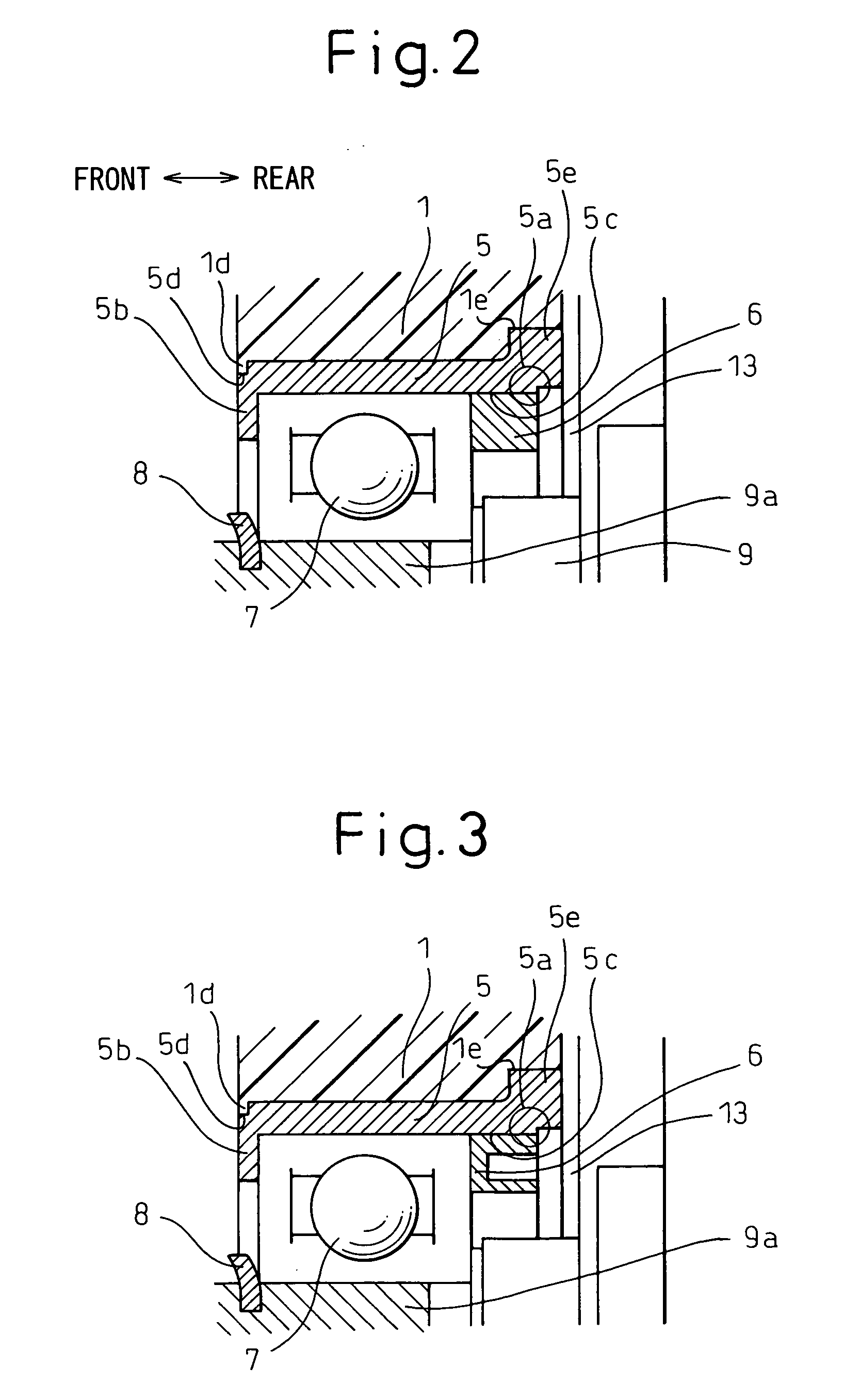

[0040]FIGS. 1 and 2 schematically show a power transmission apparatus according to the present invention. FIG. 1 shows a longitudinal sectional view of an upper half of a power transmission apparatus and FIG. 2 shows an enlarged partial sectional view of a sleeve ring and its surroundings in a power transmission apparatus shown in FIG. 1. In FIGS. 1 and 2, the elements corresponding to those in the prior art shown in FIGS. 11 and 12 are designated with the same reference numerals.

[0041] The structure of the power transmission apparatus shown in FIG. 1 will be discussed below. The power transmission apparatus transmits the external power supplied from an engine, etc., through a belt (not shown) to a compressor (not shown). The power transmission apparatus is comprised of a pulley 1 to which the belt is wound, a hub 2 which connects the pulley 1 to a rotating shaft 4 of the compressor, a torque limiter 3 which connects the pulley 1 to the rotating shaft 4 and breaks the connection whe...

second embodiment

[0060] In a power transmission apparatus according to the present invention, the bearing can be secured to the sleeve ring by means of connecting methods other than calking, such as crimping, adhering or welding, etc.

third embodiment

[0061] In a power transmission apparatus according to the present invention, the following effects can be further expected.

[0062] As the bent portion is made of a separate piece from the sleeve ring body, the sleeve ring and the bent portion can be simplified in shape, and thus the sleeve ring can be more easily machined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com