Retainer and method for attaching lines to lightweight elements of means of transport, in particular to sandwich panels of aircraft

a technology of lightweight elements and retainers, which is applied in the direction of electrical equipment, building materials handling, construction, etc., can solve the problems of increased weight, danger of losing parts, and the fact that known retainers are only suitable to a limited extent for uncomplicated line attachment, and achieve the effect of fast and simple line attachmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

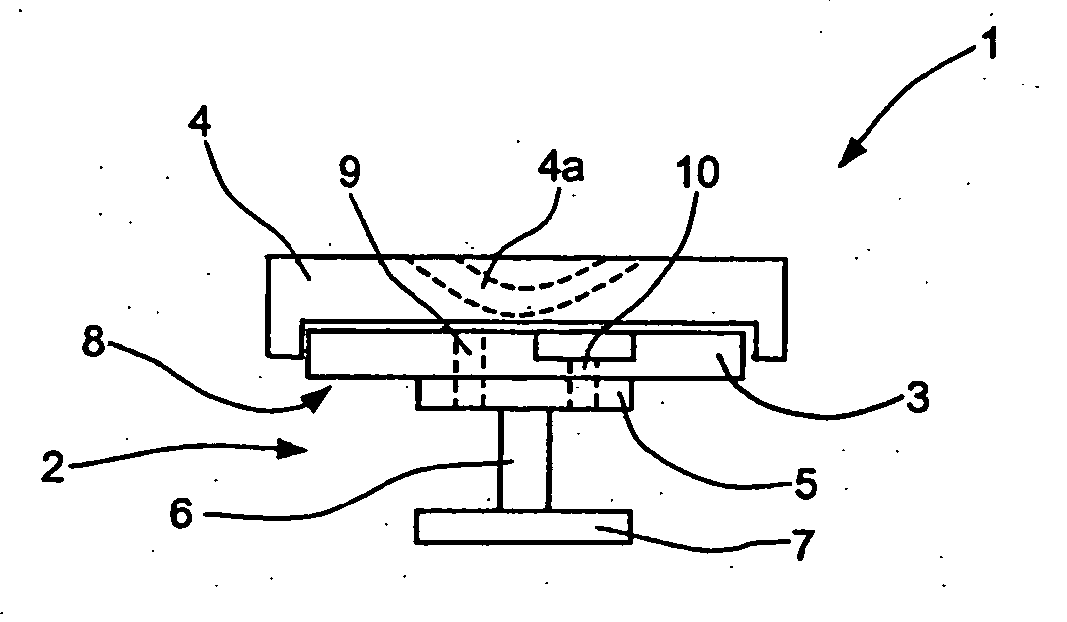

[0024]FIG. 1 shows a front view of a first embodiment variant of a holder 1 with a retaining stud 2.

[0025] The retaining stud 2 is arranged on a base plate 3. The base plate 3 and the retaining stud 2 are designed in one piece and together form the retainer 1. The retainer 1 can be made from a suitable material, for example in the injection moulding process, so as to reach through. Furthermore, the plastic material can also comprise fibre reinforcement.

[0026] An adapter 4 is attached to the base plate 3. Firm connection of the adapter 4 to the base plate 3 is by connection means (not shown in detail) such as for example snap-on elements or the like. In the adapter 4 a lead-through 4a for an attachment means, for example for a cable tie, is provided to attach one or several lines directly to the adapter 4.

[0027] In one embodiment variant of the adapter 4, said adapter 4 comprises accommodation means to connect to counterpieces located on the line. The accommodation means, the line ...

second embodiment

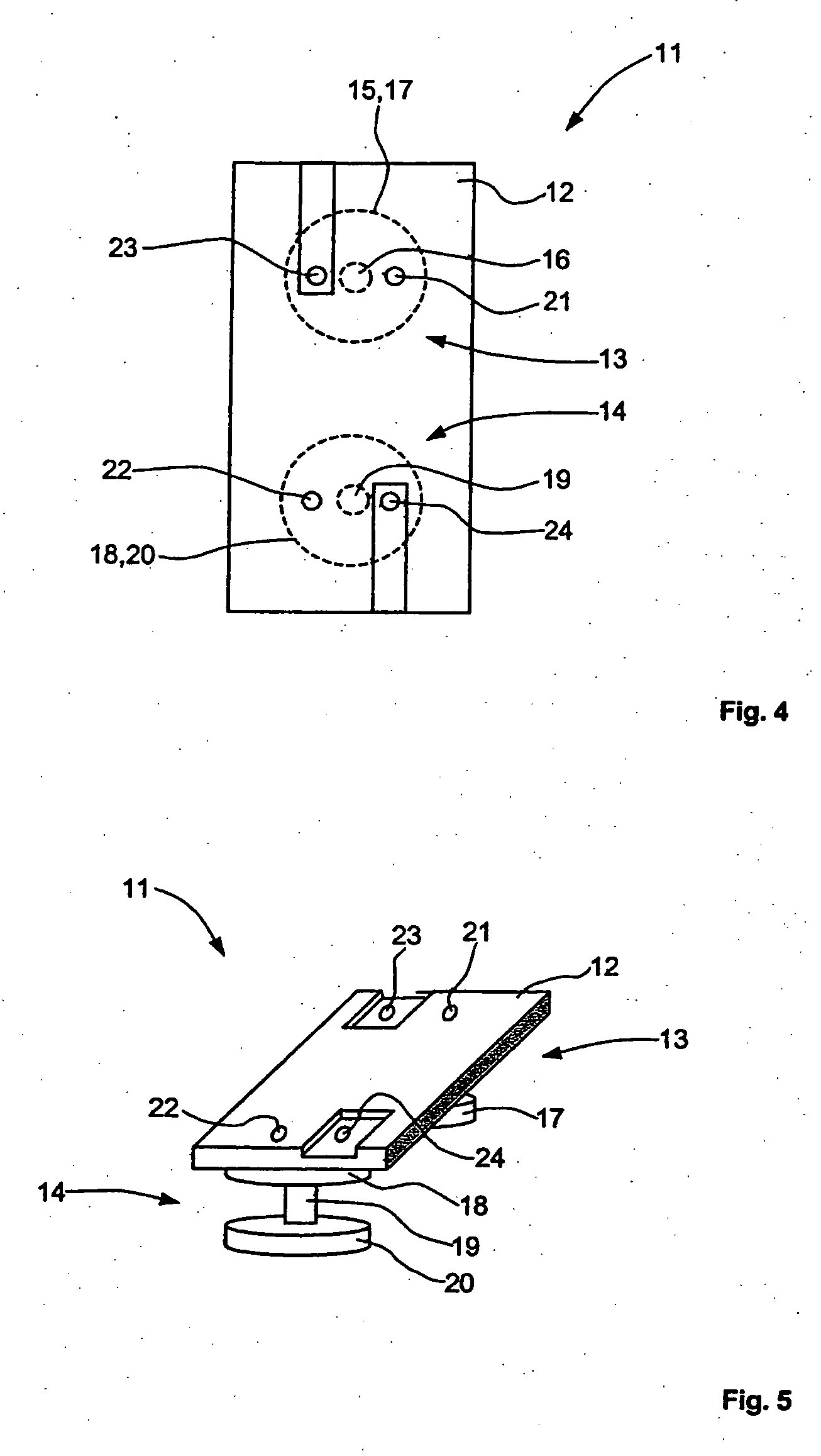

[0041]FIG. 4 shows a top view of a second embodiment variant of a retainer.

[0042] In a way that is different from the first embodiment variant of the retainer 1, the retainer 11 according to the second embodiment variant comprises a base plate 12 with two retaining studs 13, 14 so that rotation of the retainer 11 as a result of torsional forces is avoided.

[0043] Among other things the holder 11 comprises a base plate 12. Underneath the base plate 12 the two retaining studs 13, 14, which are covered up by the base plate 12, are arranged. The retaining stud 13 comprises an attachment section with a top section 15, a middle section 16 and an end section 17. Correspondingly, an attachment section of the retaining stud 14 comprises a top section 18, a middle section 19 and an end section 20. The retaining stud 13, 14 and the base plate 12 are designed in one piece; they can for example be made from a plastic material in an injection moulding process. As an alternative, the plastic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com