Deodorant composition

a deodorant composition and composition technology, applied in the direction of detergent dyes, detergent compounding agents, hair cosmetics, etc., can solve the problems of maintaining the deodorizing effect of the deodorant composition for a long time, and achieve the effect of no deodorizing performance decrease, excellent deodorizing effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

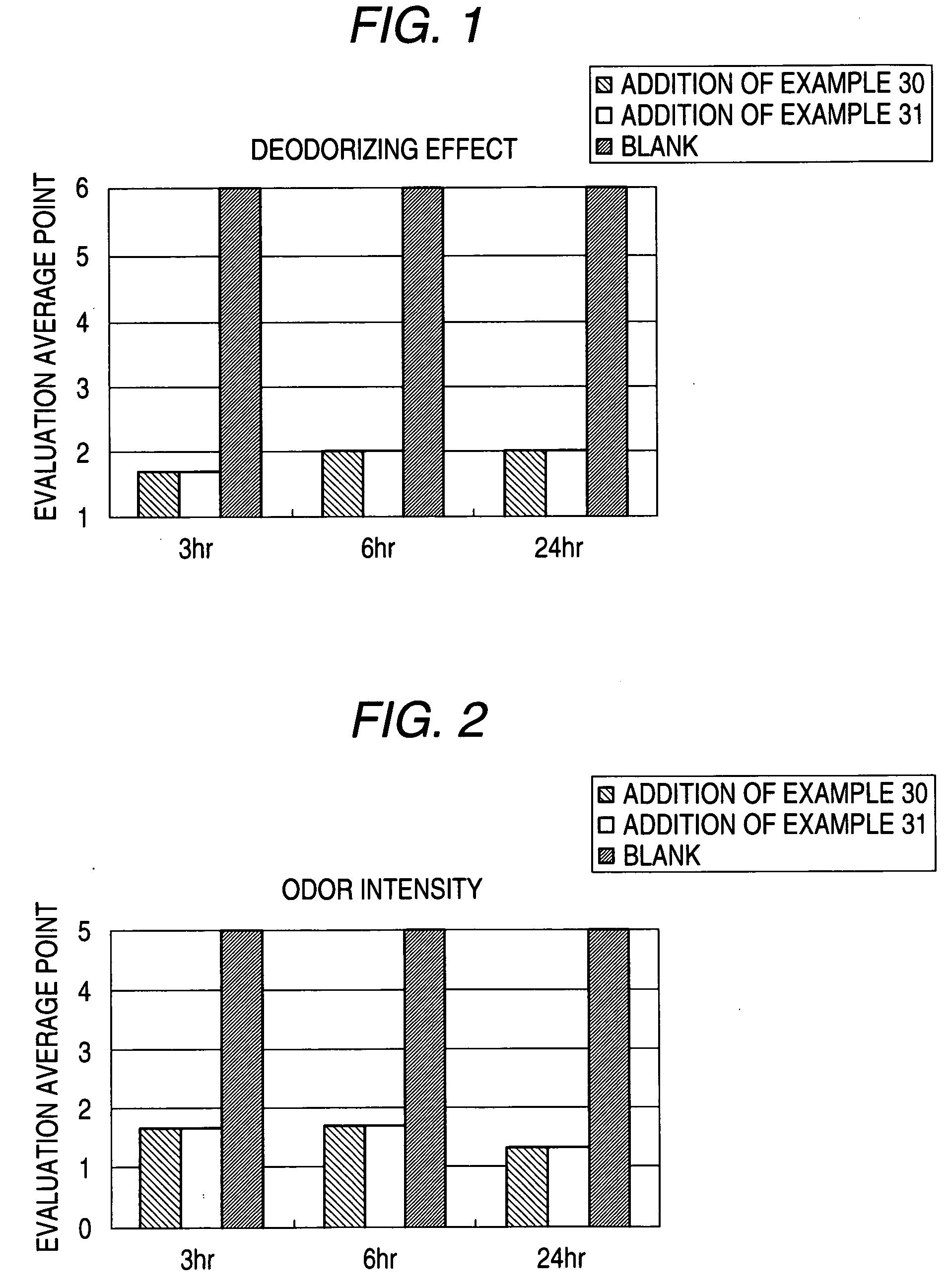

Image

Examples

example 1

Preparation of Deodorant Composition

[0129] A deodorant composition was obtained by adding 1 mol of each polyphenol described in Table 1 to the inside of a stirring vessel containing 50 mL of a 0.05M Na2CO3 solution (pH 11.2) and stirring the whole at 25° C. under conditions that air could freely flow and the surface of the reaction liquid could thoroughly come into contact with the air or allowing it to stand after the stirring under the same conditions. The stirring time and standing time are shown in Table 1.

example 2

Deodorizing Effect on Methyl Mercaptan

[0130] Into a 50 mL vial were placed 2 mL of the deodorant composition of Example 1 and 4 μL of a 15% aqueous solution of methyl mercaptan (Tokyo Kasei Kogyo Co., Ltd.) and the vial was capped with Parafilm, followed by stirring at 25° C. After 10 minutes, 50 mL of the head space gas in the vial was passed through a gas detecting tube (manufactured by Gastech Corporation) to measure the concentration of sulfur compounds, which remained in the gas and were malodor components, and a deodorization rate was calculated according to the following expression. The results are shown in Table 1.

Deodorization rate (%)=100×{1−(A / B)}

[0131] In the above expression, A means the measured concentration of the malodor components and B means the concentration of the malodor components measured in the control.

[0132] The control was prepared by adding a 0.05M Na2CO3 solution (pH 11.2) instead of the addition of 2 mL of the deodorant composition of Example 1.

[013...

example 3

Preparation of Deodorant Composition

[0137] One mmol of chlorogenic acid was added to the inside of a stirring vessel containing 50 mL of a 0.05M Na2CO3 solution (pH 11.2) and the whole was stirred at 25° C. for 3 hours under conditions that air could freely flow and the surface of the reaction liquid could thoroughly come into contact with the air. Then, the reaction liquid was freeze-dried to obtain 460 mg of an ocher powdered deodorant composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com