Paper feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

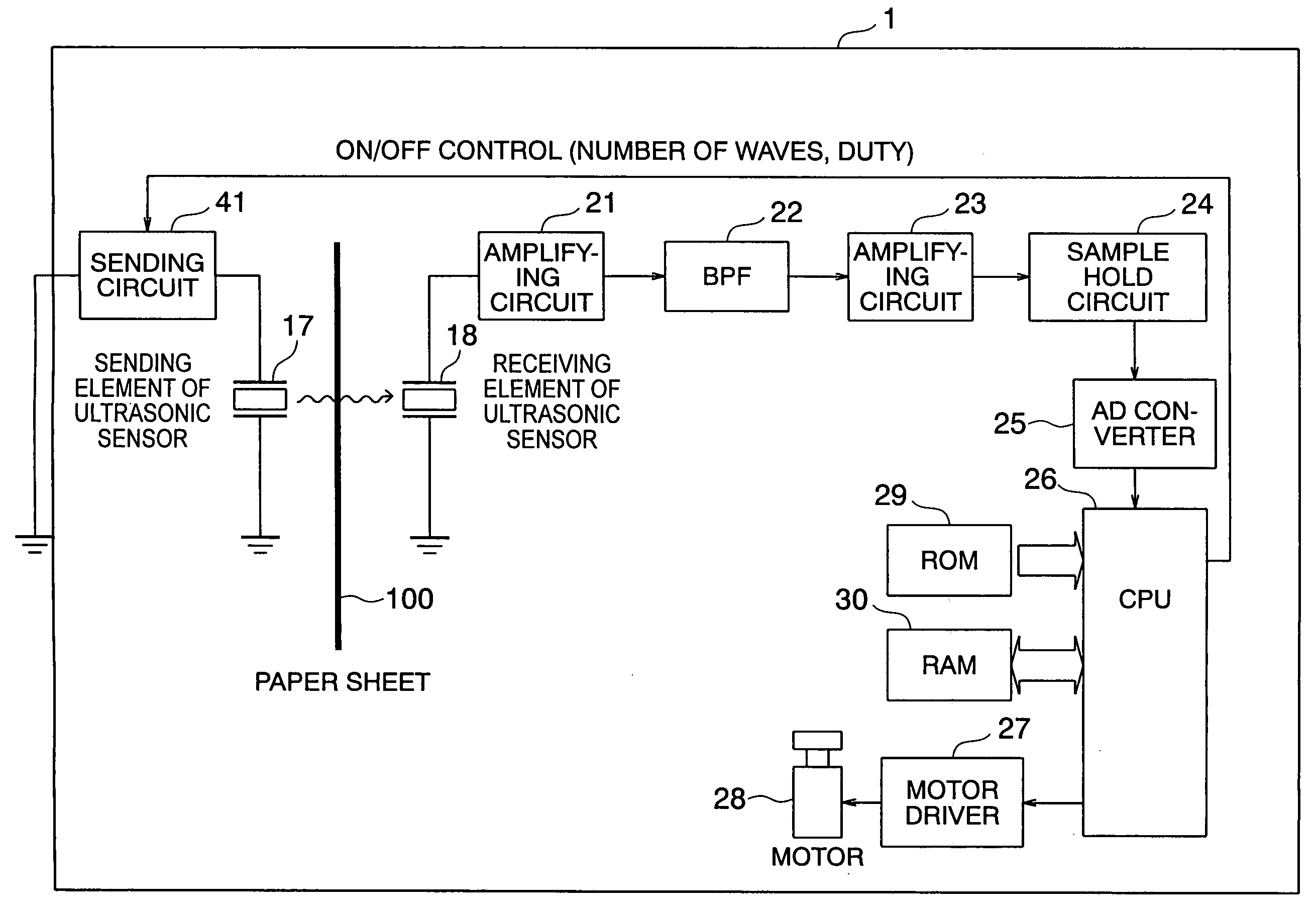

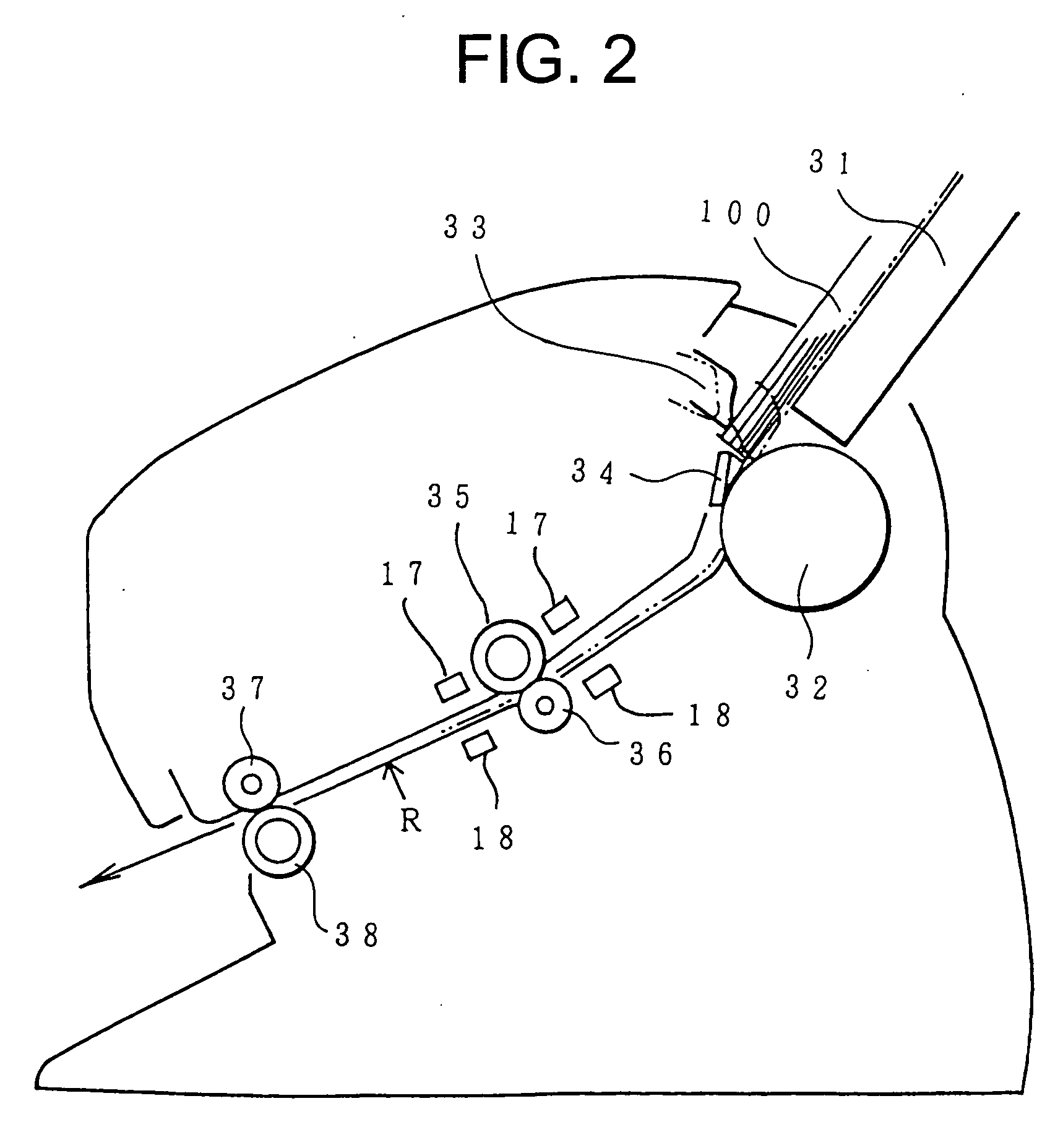

[0027]FIG. 1 and FIG. 2 are structural diagrams of a scanner, showing the schematic structure of a scanner to which a sheet feeding apparatus according to the present invention is applied. Particularly, FIG. 1 shows an external view of the scanner, and FIG. 2 shows a schematic section of a scanner.

[0028] This scanner is formed integrally with the sheet feeding apparatus. The sheet feeding apparatus, as shown in FIG. 2, comprises a paper sheet mounting table (shooter) 31, a pick roller 32, a pick arm 33, a separating pad 34, feed rollers 35 and 36, and discharge rollers 37 and 38. And, the sheet feeding apparatus further comprises the sending element of the ultrasonic sensor 17 and the receiving element of the ultrasonic sensor 18 of an ultrasonic detector 1 to be described afterwards. In FIG. 2, the two-dot chain line represents the transfer path of paper sheets 100 and the arrow R represents the reading position of the paper sheets 100.

[0029] The paper sheets 100 mounted on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com