Energy absorbing sports helmet

a sports helmet and energy-absorbing technology, applied in the field of headgear, can solve the problems of head injuries, long-term damage to thinking abilities, coma or death, and are leading causes of death and disability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A detailed description of the preferred embodiments of the present invention will now be given referring to the accompanying drawings.

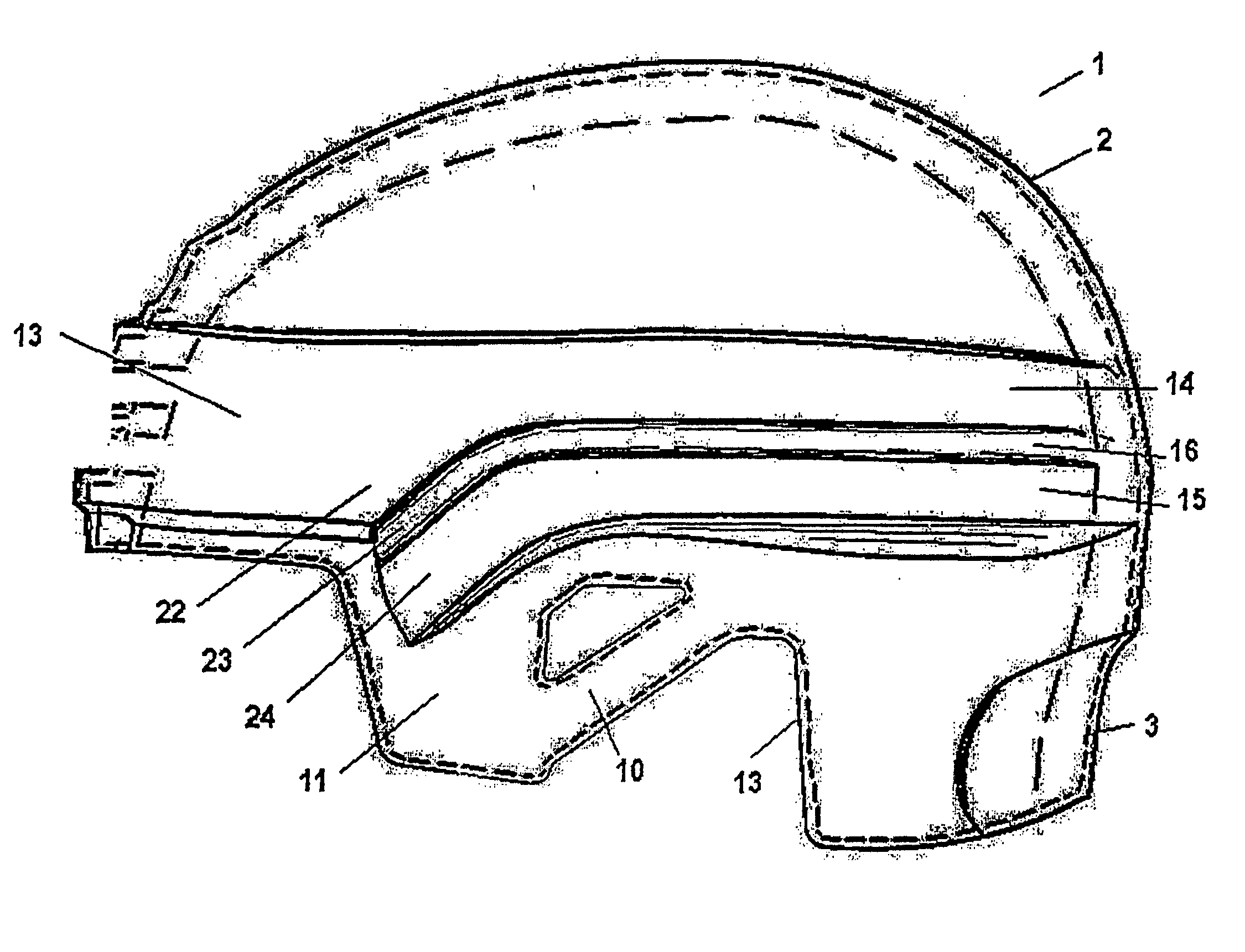

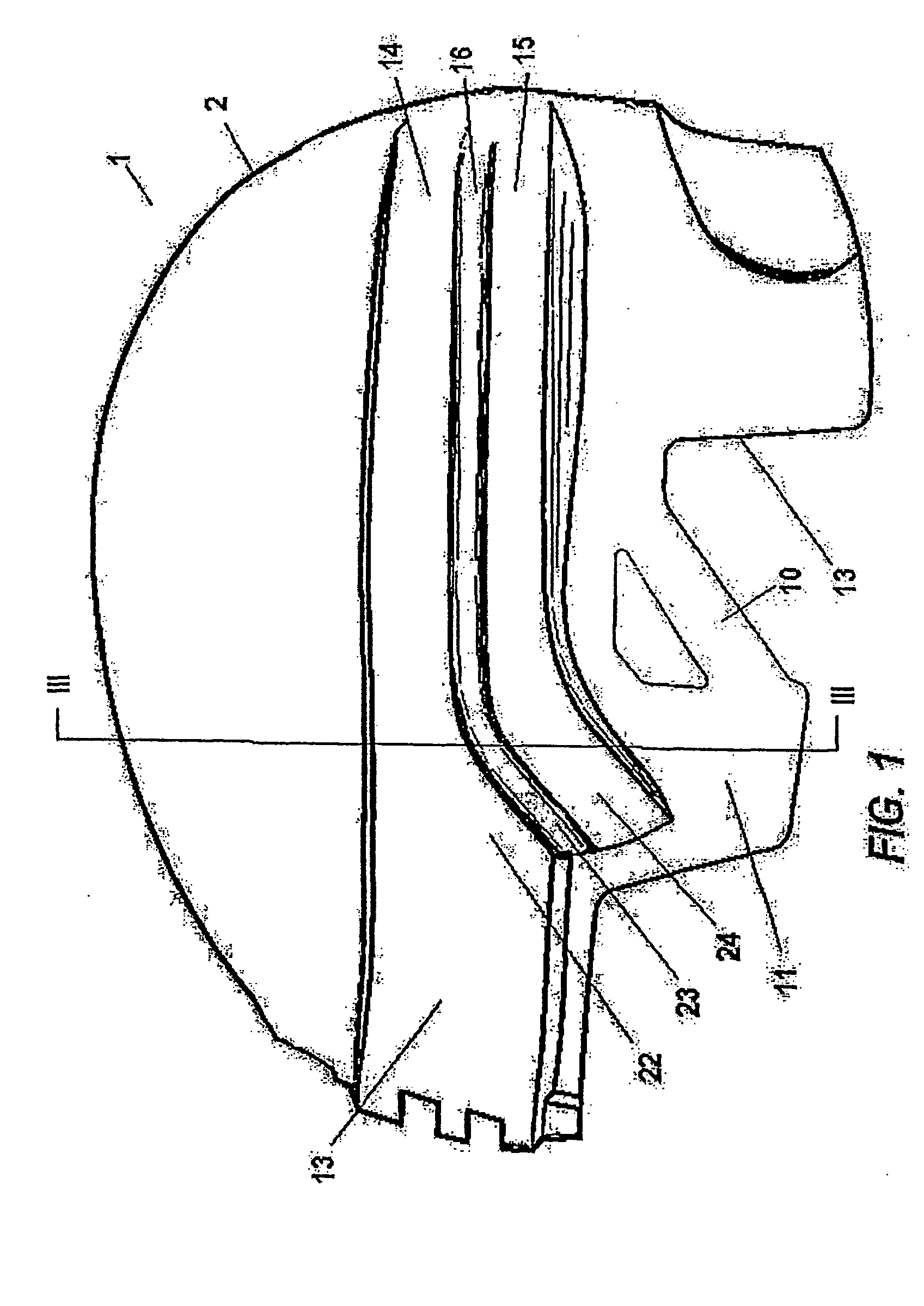

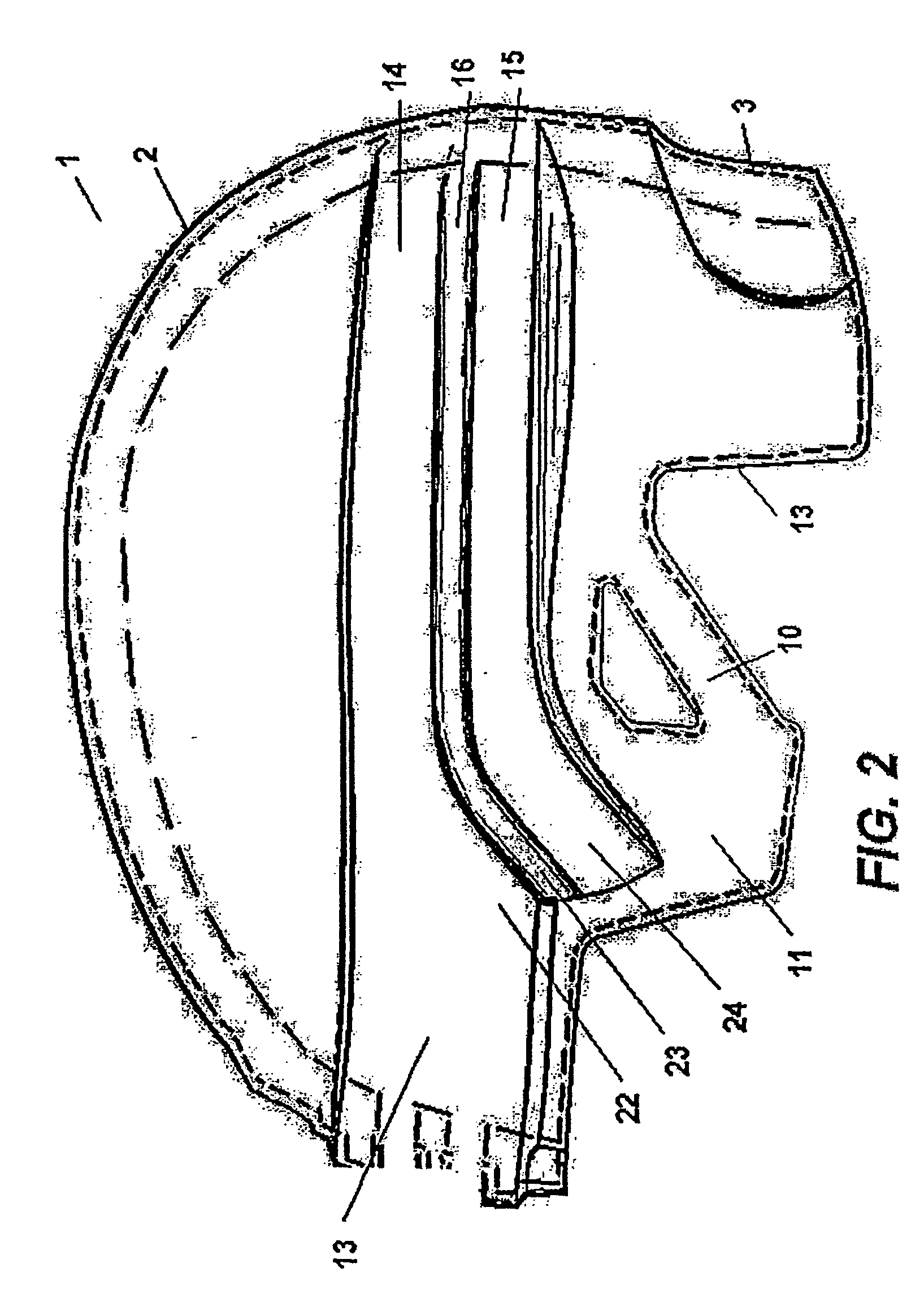

[0038] Referring to FIGS. 1 and 2, a side view of a preferred embodiment of the energy-absorbing helmet is illustrated. The helmet 1 comprises a helmet shell 2 and an energy absorbing liner insert 4 having an exterior surface 5 that conforms to the interior surface 3 of the helmet shell 2. The helmet shell 2 itself is comprised of thermoset plastic with reinforcing structures disposed thereon. The reinforcing structures will be described in more detail below.

[0039] Referring to FIG. 3, a sectional view of the energy absorbing liner insert 4 without the helmet shell 2 along lines III-III is illustrated. The energy absorbing liner insert 4 is comprised of a foam layer 6 and a silicone layer 7. The silicone layer 7 is bonded to the foam layer 6, and the interior surface 8 formed by the silicone layer 7 is in contact with the athlete's head.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com