Ultrasonic in-process monitoring and feedback of resistance spot weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

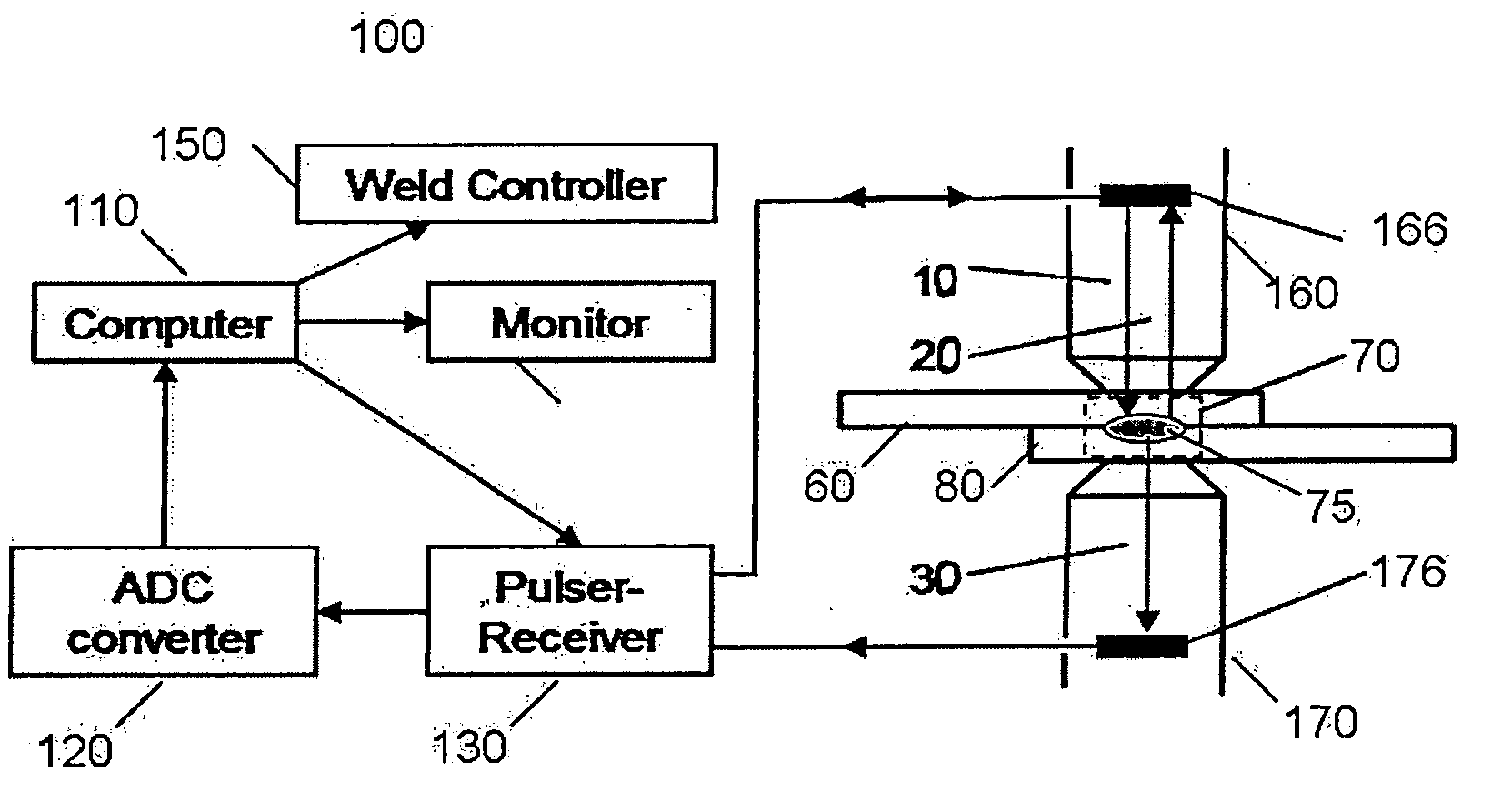

[0020] Referring to FIG. 1, an apparatus 100 for ultrasonic in-process monitoring and feedback according to the invention includes a computer 110, analog-digital converter (ADC) 120, pulser-receiver 130, monitor 140, weld controller 150 and acoustic transmitter-receiver probes 166, 176 mounted within weld electrodes 160, 170.

[0021] Each of the electrodes 160, 170 includes a probe 166, 176 capable of emitting and receiving acoustic waves 10, 20 and 30. The computer 110 sends commands to the weld controller 150 and the pulser-receiver 130. The weld controller 150 clamps the electrodes 160, 170 and starts welding. Simultaneously, the pulser-receiver 130 sends electrical pulses to a probe 166 located in one of the electrodes. The electrical energy is converted into mechanical energy in the form of acoustic waves 10.

[0022] The waves 10 propagate through the first and second metal layers 60, 80 and the weld zone 70 as long as the metal is transparent to sound waves. The weld zone 70 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com