Building exterior wall-coating emulsion compositions and building exterior walls

a technology for building exterior walls and emulsion compositions, applied in the direction of adhesive types, coatings, graft polymer adhesives, etc., can solve the problems of affecting the application of the product, affecting the application effect, and difficult to introduce a large amount of silicone resin components in the coating, etc., to achieve the effect of improving water resistance, weather resistance, water repellency and heat resistance, and improving elasticity

Inactive Publication Date: 2006-03-30

NISSHIN CHEM IND CO LTD

View PDF7 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0007] Therefore, an object of the present invention is to provide an emulsion composition for building exterior walls capable of forming an elastic, flexible coating having water resistance, weather resistance, water repellency, adhesion and heat resistance and maintaining these properties over a long period of time; and a building exterior wall coated therewith.

[0017] The emulsion composition for building exterior walls of the invention is capable of forming an elastic, flexible coating which is endowed with water resistance, weather resistance, water repellency, adhesion and heat resistance and maintains these properties over a long period of time. The emulsion composition can thus be used as a base in a variety of paints and coating agents. The incorporation of a crosslinker and a crosslinking reaction catalyst in the emulsion composition enables further improvements in elasticity, flexibility, water resistance, weather resistance, water repellency and heat resistance. The emulsion composition is thus very advantageous in practical application to building exterior walls.

Problems solved by technology

Unfortunately, they essentially lack water resistance and weather resistance.

However, in the former approach wherein a vinyl polymerizable functional group-containing alkoxysilane is emulsion polymerized together with a radical polymerizable vinyl monomer, more alkoxy groups are retained because of inhibited hydrolysis and it is difficult to introduce a large amount of silicone resin component in a coating.

Thus important properties such as weather resistance are not improved to a level that is considered satisfactory for exterior applications.

The latter approach fails to offer satisfactory coating properties because active alkoxy groups are prone to hydrolysis over time, allowing an alcohol which is an organic solvent to form as a by-product within the system, and additionally because the degree of polymerization changes with time.

As mentioned above, the prior art known methods fail to provide satisfactory coating properties.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0075] Examples of the invention are given below together with Comparative Examples for illustrating the invention. Examples are not intended to limit the invention thereto. All parts and percents are by weight.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Login to View More

Abstract

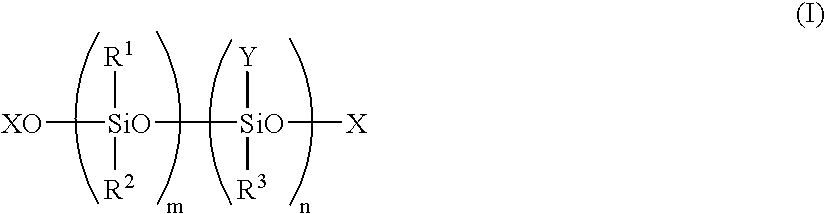

An emulsion composition for building exterior walls is provided comprising in admixture, [A] a graft copolymerized emulsion obtained by adding to (1) an oil-in-water type emulsion containing at least one organopolysiloxane having an organic group containing a radical reactive group or SH group, (2) a monomer or monomeric mixture containing at least 70 wt % of at least one monomer selected from acrylic and methacrylic monomers and effecting emulsion graft polymerization of component (2) to the organopolysiloxane, and [B] a silicone resin-containing emulsion. The emulsion composition is capable of forming an elastic, flexible coating which is endowed with water resistance, weather resistance, water repellency, adhesion and heat resistance and maintains these properties over a long period of time. It can thus be used as a base in a variety of paints and coating agents.

Description

CROSS-REFERENCE TO RELATED APPLICATION [0001] This application is a continuation-in-part of copending application Ser. No. 10 / 785,993 filed on Feb. 26, 2004, the entire contents of which are hereby incorporated by reference.TECHNICAL FIELD [0002] This invention relates to an emulsion composition for building exterior walls, comprising a graft copolymerized emulsion obtained through the emulsion graft copolymerization of a (meth)acrylic monomer or monomeric mixture thereof to an organopolysiloxane and a silicone resin-containing emulsion, and more particularly, to such an emulsion composition for building exterior walls capable of forming an elastic, flexible coating having water resistance, weather resistance, water repellency, adhesion and heat resistance and maintaining these properties over a long period of time. It also relates to a building exterior wall coated with the emulsion composition. BACKGROUND OF THE INVENTION [0003] In the paint and coating field, the transition of di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F283/00C08F283/12C08L51/08C09D151/08C09J151/08

CPCC08F283/12C08L51/085C09D151/085C09J151/085C08L2666/02C08F283/124C08G77/12C08G77/42C08F220/10C09D183/10C08L83/00C08K5/57

Inventor OKUDA, HARUKAZUHATANAKA, MASAHIDEYAMAMOTO, AKIRA

Owner NISSHIN CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com