Golf putter with lead glass head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a detailed description of a preferred embodiment of the present invention and the best presently contemplated mode of its production and practice. This description is further made for the purpose of illustrating the general principles of the invention but should not be taken in a limiting sense, the scope of the invention being best determined by reference to appended claims.

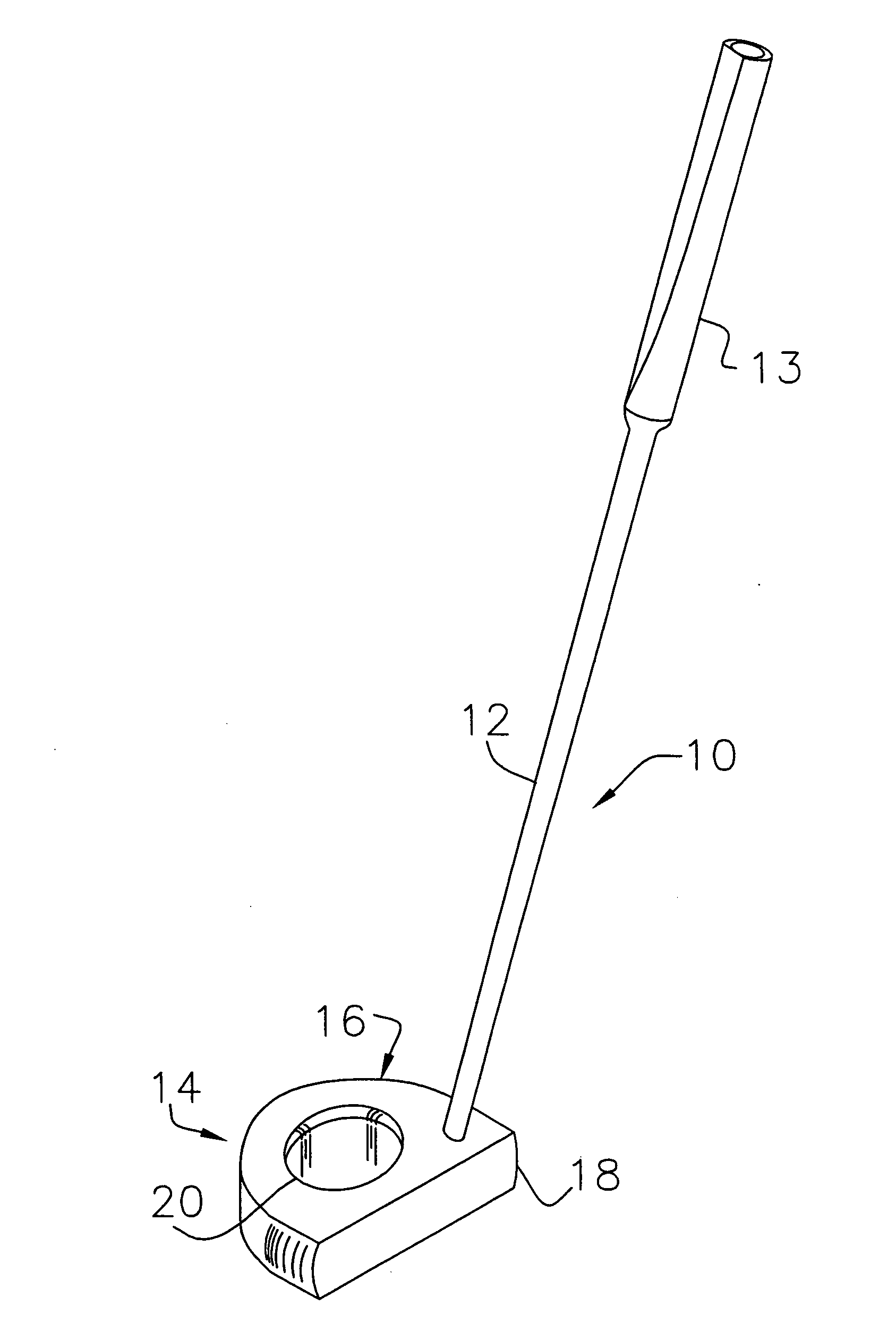

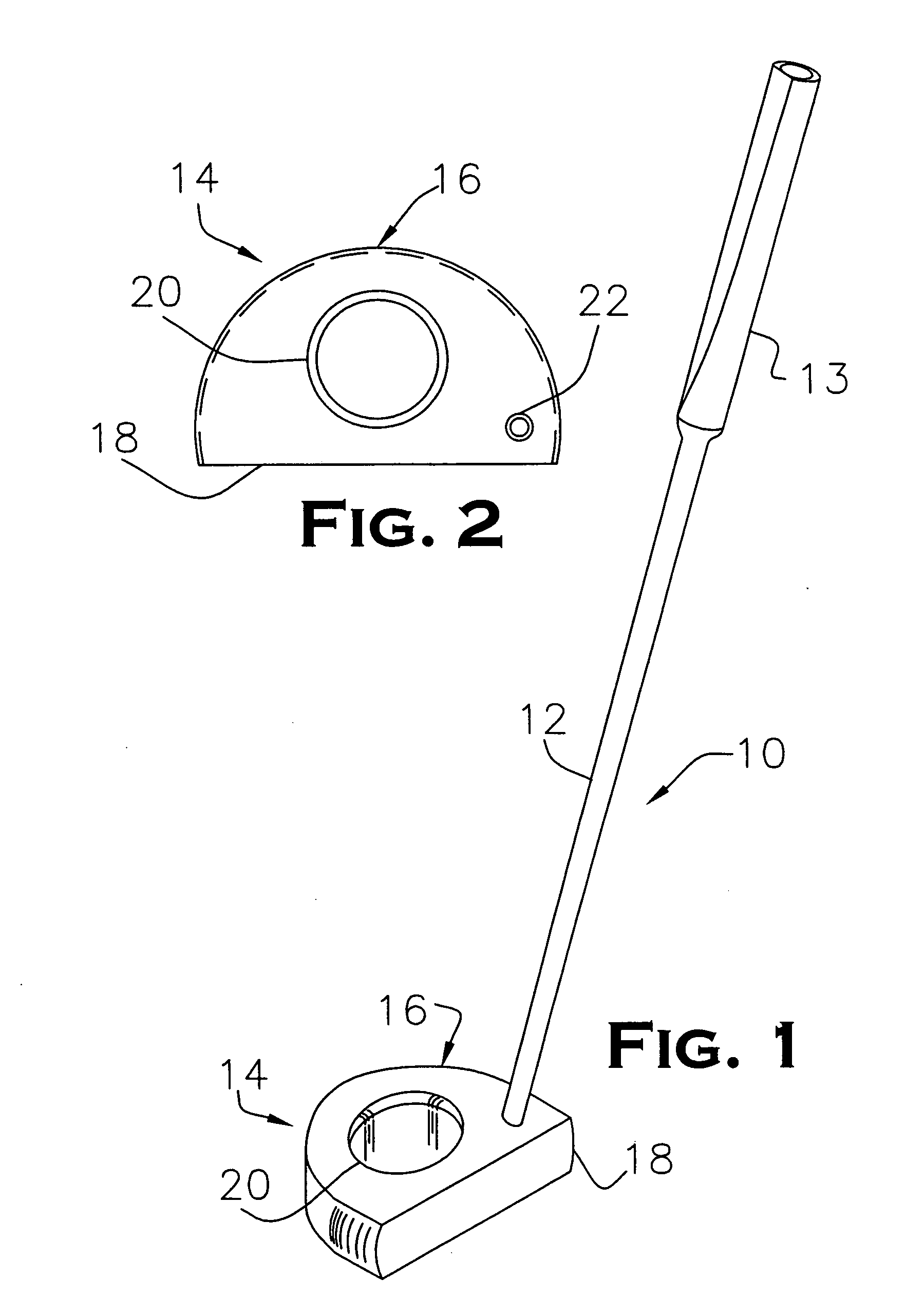

[0019] Referring now to FIG. 1, a golf putter, generally designated 10, is shown including a shaft member 12 fitted with a grip 13 attached along the upper length of the shaft and a putter head 16, constructed in accordance with the present invention, affixed to the bottom end of the shaft member. The shaft member 12 is a conventional member that is generally cylindrical through its length, but may be tapered slightly and bent at one or more angles along the bottom portion of the shaft to accommodate a proper shaft attachment to the putter head 16 with any offset or dimensional spacing d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com