Method for deposition onto a substrate and method for producing photo conductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

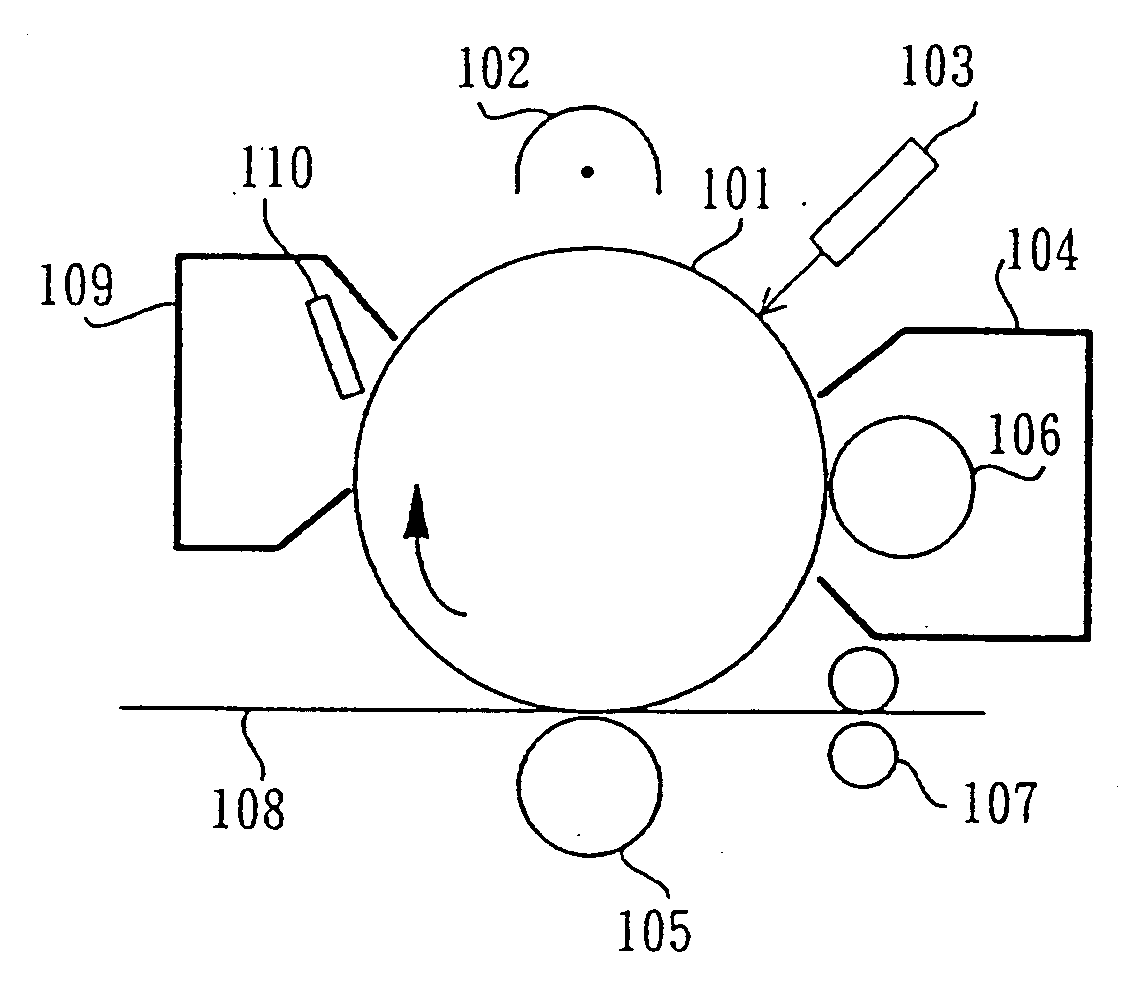

[0033]FIG. 1 shows the composition of the periphery of the image forming unit in an image forming apparatus wherein a photo conductor (hereinafter referred to as photosensitive material) is applied that utilizes a substrate deposited onto a substrate by the method for deposition related to the first embodiment of the present invention. Furthermore, in the following the member whereon a carrier generation layer and a carrier transport layer are deposited onto a conductive base material is referred to as a “substrate” in this specification.

[0034] As shown in this figure, an electric charging device 102 close to the photosensitive material 101, an exposure apparatus 103, a developing apparatus 104, and a transfer apparatus 105 are arranged in the related image forming apparatus. The photosensitive material 101 has a protective surface layer. The composition of the related protective surface layer will be described later. The photosensitive material 101 rotates in the direction of the ...

second embodiment

[0064]FIG. 11 is an outline of an example of a CVD deposition apparatus used when implementing the method for deposition onto a substrate related to the second embodiment of the present invention. FIG. 12 shows a view from above the inside of the vacuum container of the CVD deposition apparatus shown in FIG. 11.

[0065] The CVD deposition apparatus 1100 shown in FIG. 11 differs from the CVD deposition apparatus 300 shown in FIG. 3 by the fact that ground members 1101 are enclosed at the inside of the substrates B. According to the CVD deposition apparatus 1100 related to the second embodiment, the space required for the ground members 307 which require independent space can be reduced compared to the CVD deposition apparatus 300 related to the first embodiment. Therefore, this CVD deposition apparatus 1100 is suitable when manufacturing a greater quantity of photosensitive material.

[0066] As shown in FIG. 12, the ground members 1101 have a hollow cylindrical shape. The substrates B ...

third embodiment

[0074] The method for deposition onto a substrate related to the third embodiment differs from the method for deposition onto a substrate related to the second embodiment by the fact that the gas pressure while plasma generates in proportion to the distance between the substrates B and the ground members 1101 as well as the high-frequency output to the substrates B in the CVD deposition apparatus 1100 related to the second embodiment are both controlled. By controlling the gas pressure while plasma generates in proportion to the distance between the substrates B and the ground members 1101 in this manner makes it possible to optimize the state of the plasma around the periphery of the substrates B and to also optimize the deposition of coatings onto the substrates B.

[0075]FIG. 14 shows an example of a Paschen curve utilized when the method for deposition onto a substrate related to the third embodiment controls the gas pressure while plasma generates in proportion to the distance (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com