A composition-controllable copper-zinc-tin thin film material, a copper-zinc-tin-sulfur-based solar cell, and a preparation method for both

A thin-film material, copper-zinc-tin technology, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of good crystallinity, low solution stability, and large reduction potential gap, etc., to achieve improved photoelectric performance, The product is stable and efficient, and the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

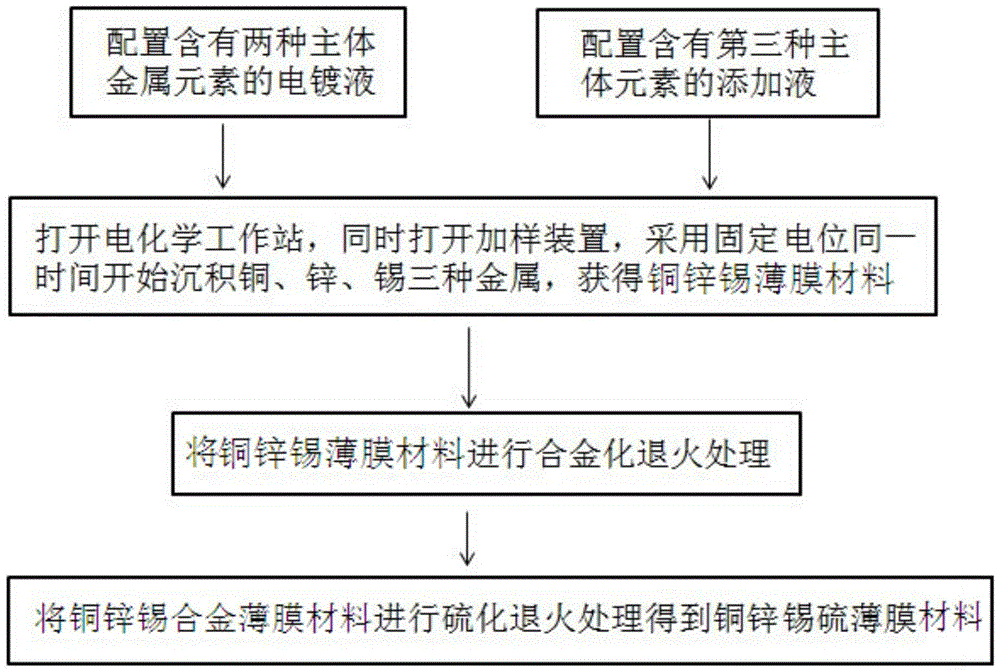

[0047] A kind of preparation method of copper-zinc-tin film material of the present invention, it comprises the steps:

[0048] 1) The copper-zinc-tin thin film material contains at least three main metal elements of copper, zinc and tin; the electroplating solution contains any two of the three main metal elements; the additive solution contains the third main metal element that is missing in the electroplating solution element;

[0049] 2) There is at least one conductive electrode in the electroplating solution as the first electrode, and the film substrate to be plated is used as the second electrode; the film substrate to be plated is a conductive substrate or a substrate covered with a conductive film;

[0050] 3) When energizing between the first electrode and the second electrode, add the additive solution at a controlled rate, that is, start to simultaneously deposit three metal films containing copper, zinc and tin, and obtain a substrate on which a copper-zinc-tin m...

example 1

[0059] A kind of preparation method of copper-zinc-tin film material of the present invention, the steps are as follows:

[0060] Configure zinc-tin binary metal mixed solution as electrolyte: 0.07M zinc sulfate, 0.05M tin sulfate, sodium citrate complexing agent, pH 3. Configure the third metal salt solution as the additive solution: 0.4M copper sulfate and sodium citrate as complexing agent. The substrate as the second electrode is connected to the conductive electrode as the first electrode and placed in the electrolytic solution, and the potential of the second electrode is negative relative to the first electrode. Add the additive solution at a controlled rate, the addition amount is 15ml / min, start depositing copper, zinc, and tin at the same time with a fixed potential to form a metal film, the potential is -1.7V, and the deposition time is 10min. The substrate of the zinc-tin metal film, that is, the material of the copper-zinc-tin film.

example 2

[0062] A kind of preparation method of copper-zinc-tin film material of the present invention, the steps are as follows:

[0063] Prepare copper-zinc binary metal mixed solution: 0.08M zinc sulfate, 0.01M copper sulfate, sodium citrate complexing agent, pH 6. Configure the third metal salt solution as the additive solution: 0.3M tin sulfate and sodium citrate as complexing agent. The substrate as the second electrode is connected to the conductive electrode as the first electrode and placed in the electrolytic solution, and the potential of the second electrode is negative relative to the first electrode. Add the additive solution at a controlled rate, the addition amount is 10ml / min, start depositing copper, zinc, and tin at the same time with a fixed potential to form a metal film, the potential is -1.7V, and the deposition time is 7min. After the electroplating is completed, copper is deposited on the surface The substrate of the zinc-tin metal film, that is, the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com