Operation control apparatus for compressor and method thereof

a technology of operation control apparatus and compressor, which is applied in the field of compressors, can solve the problems of increasing the production cost of the compressor b>12/b>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

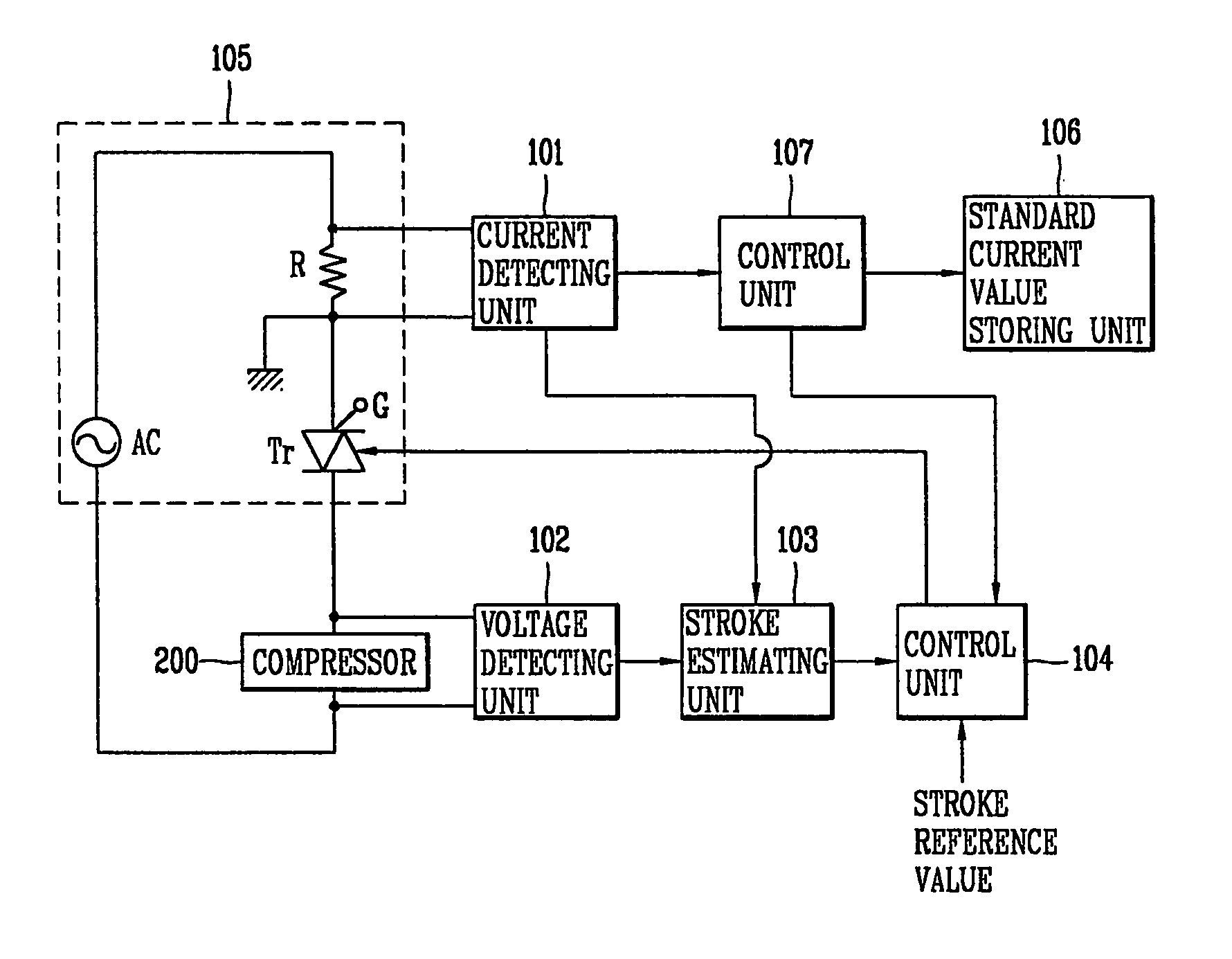

[0021]FIG. 2 is a block diagram showing a configuration of the operation control apparatus for the reciprocating compressor according to the present invention. That is, the amount of currents applied to the compressor 200 is controlled through the current control device (triac, Tr) installed at the compressor 200 without using the OLP (Over Load Protector) and the PTC thermistor. Also, when the compressor initially starts, a stroke of the compressor is estimated to slowly increase the stroke of the compressor, and varies the stroke of the compressor by turning on / off the current control device (Tr) at a certain period on the basis of the estimated stroke.

[0022] As shown therein, the operation control apparatus for the reciprocating compressor includes: a voltage detecting unit 102 for detecting a voltage applied to an interior motor (not shown) of the reciprocating compressor 200 when the reciprocating compressor is operated; a current detecting unit 101 for detecting a current appl...

second embodiment

[0028] Hereinafter, a configuration of an operation control apparatus for the reciprocating compressor according to the present invention will now be described in detail with reference to FIG. 4.

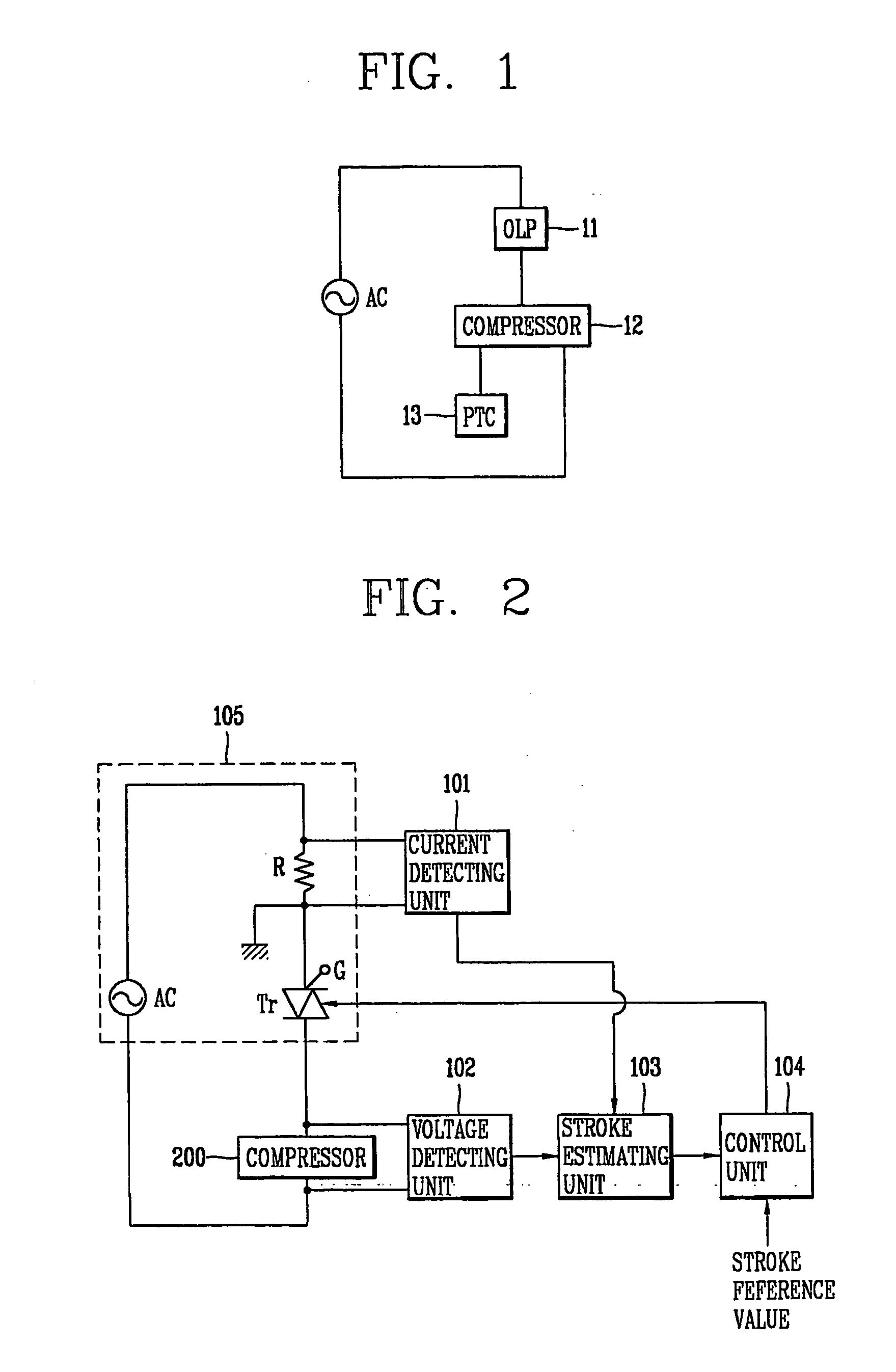

[0029]FIG. 4 is a block diagram showing the configuration of the operation control apparatus for the reciprocating compressor according to the second embodiment of the present invention. That is, in the operation control apparatus for the reciprocating compressor according to the second embodiment of the present invention, a current control device (Tr) instead of the OLP and the PTC thermistor is installed at the compressor 200, and the amount of currents applied to the interior motor of the compressor 200 is controlled through the current control device (Tr). Also, in the operation control apparatus for the reciprocating compressor according to the second embodiment of the present invention, in order to protect the compressor 200 from an overcurrent generated when the compressor 200 initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com