Control valve for variable displacement compressor

a compressor and variable-discharge technology, applied in the direction of positive-discharge liquid engines, pump components, machines/engines, etc., can solve the problems of large control valve scale, inability to perform rotational speed control, and inability to achieve the desired characteristics with eas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

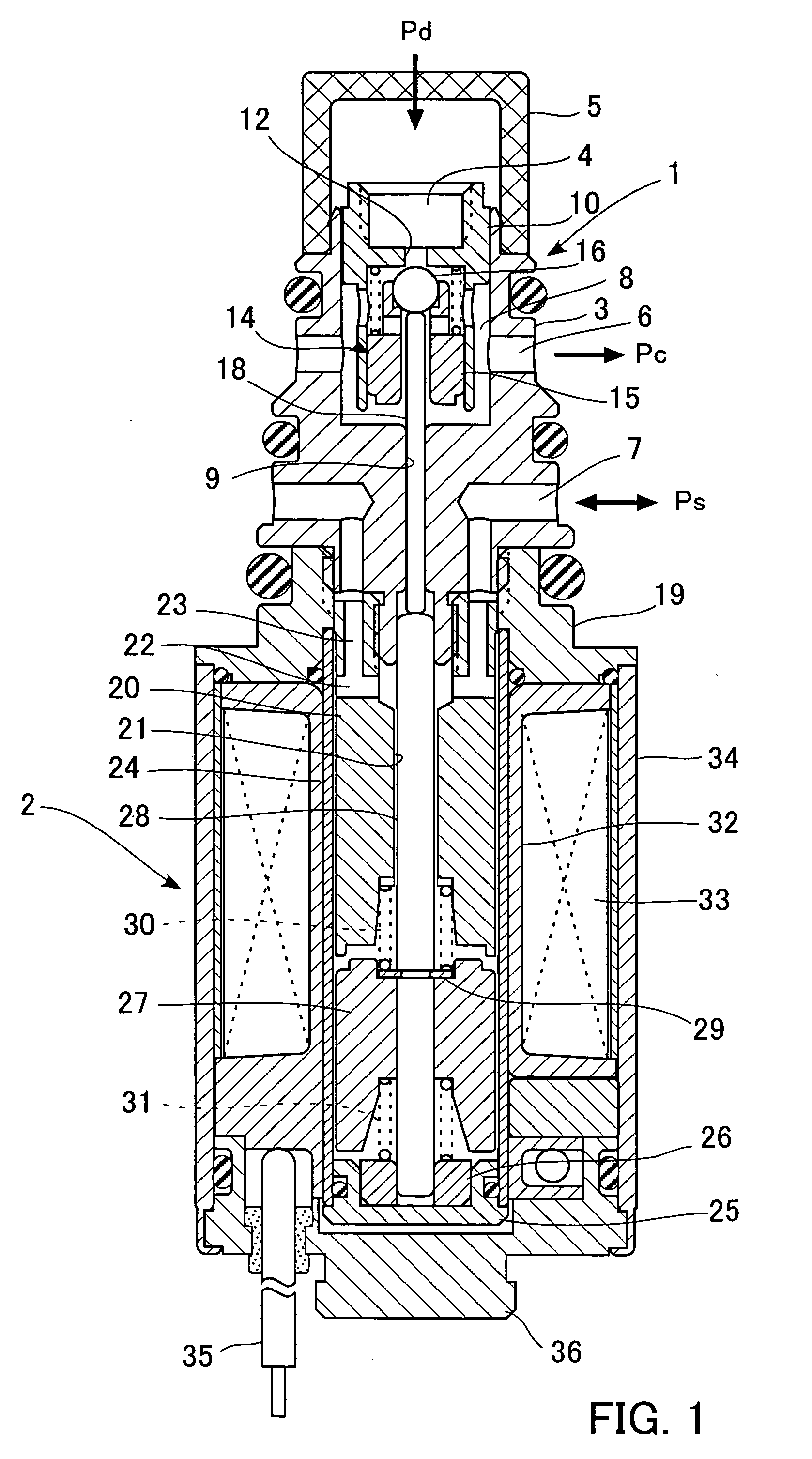

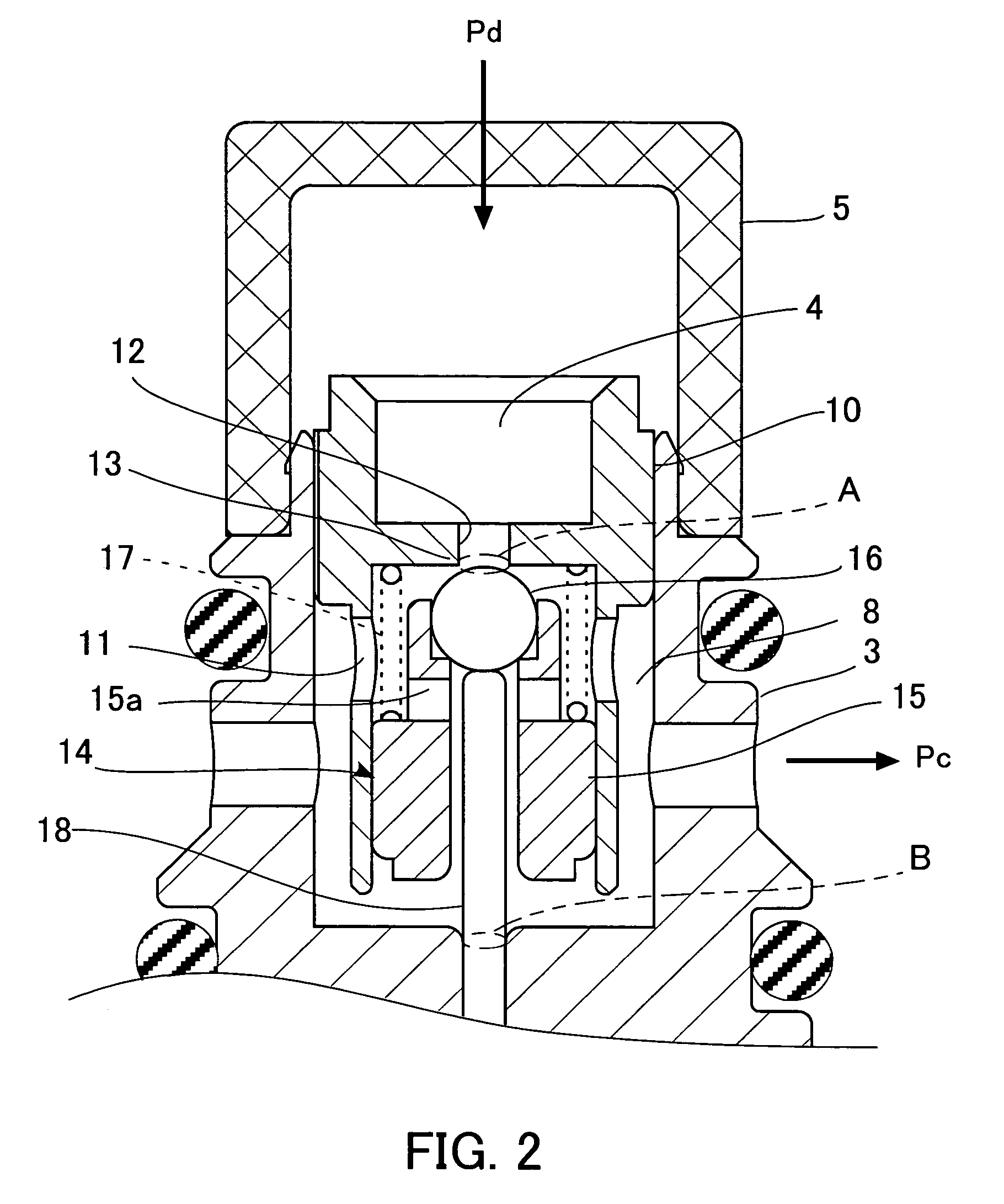

[0022]FIG. 1 is a cross-sectional view showing the arrangement of a control valve for a variable displacement compressor, according to the present embodiment, and FIG. 2 is a fragmentary expanded cross-sectional view of an upper part of the FIG. 1 control valve.

[0023] Referring first to FIG. 1, the control valve introduces part of refrigerant discharged from a variable displacement compressor, not shown, and allows the introduced refrigerant to flow into a crankcase while controlling the flow rate thereof. The control valve is formed by integrally assembling a valve-forming section 1 containing a valve section for adjusting the flow rate of refrigerant, and a solenoid 2 for controlling the valve lift of the valve section.

[0024] The valve-forming section 1 has a stepped hollow cylindrical upper body 3 having an open upper end defining therein a discharge pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com