Roof vent

a technology for roof vents and ridge vents, which is applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of increasing snow melt, leaking through roof decks and into residences, and affecting so as to improve the drafting efficiency of ridge vents and improve the effect of roof venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A new roof vent in accordance with the present invention overcomes the problems associated with roof venting that is rendered ineffective or totally useless in the face of substantial snow loads. While it should be appreciated that the teachings of the present invention are applicable to many types of roof vents, the particular type of venting design used to illustrate the present invention will be the ridge type ventilation. Ridge vents can be used on different roof types as well, including gable roofs, hip roofs, gambrel roof, and combinations of these.

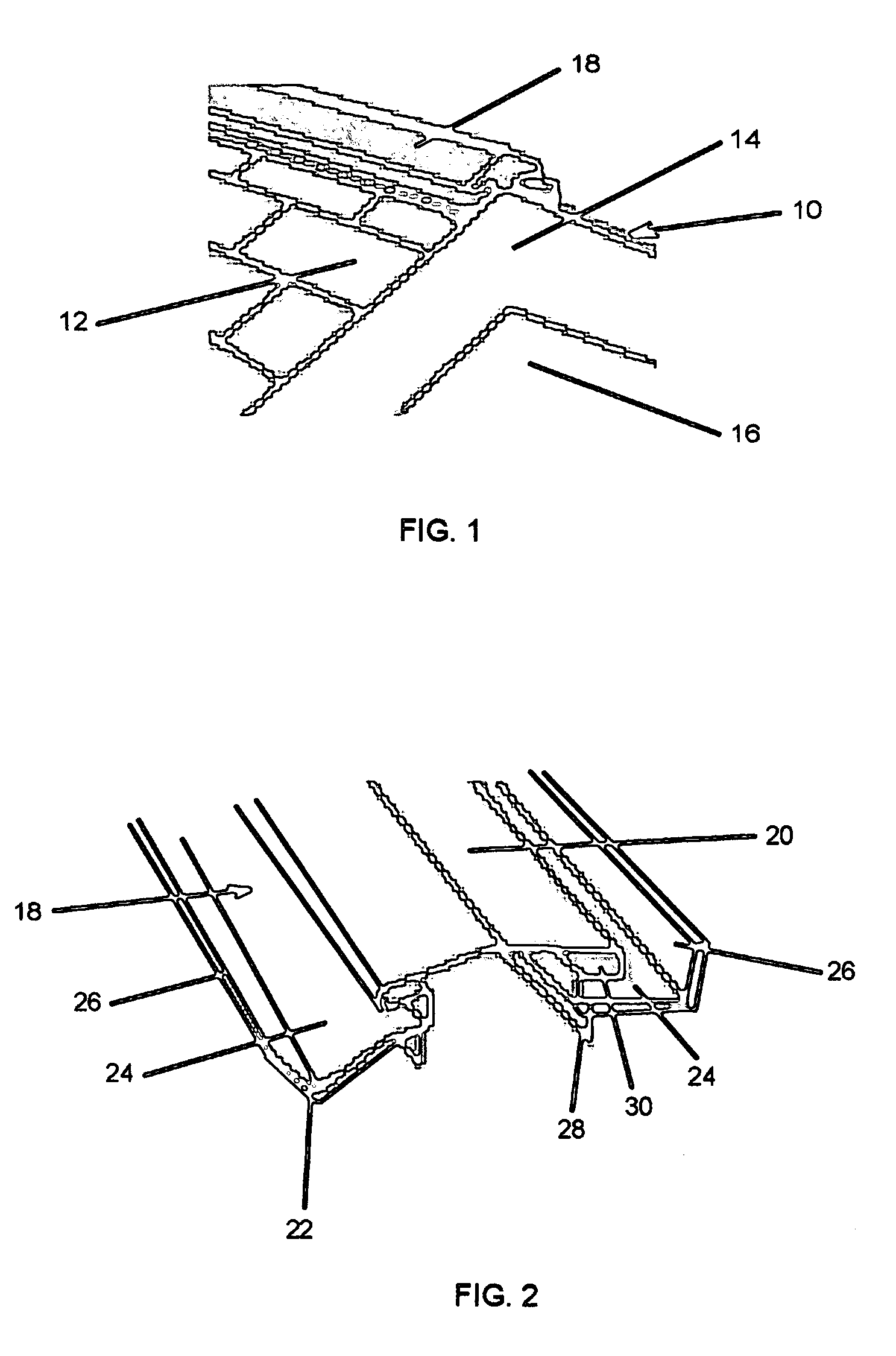

[0031] Turning to FIG. 1, a roof ventilation system of the prior art is shown as installed on roof 10, in this case a gable roof, which includes shingles 12, roof peak 14, sidewall 16 and ridge vent 18. As the name implies, the ridge vent is located on the ridge line formed at the top of the conventional style gable roof design. There is some natural symmetry in the appearance of the ridge vent since it is outwardly shaped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com