Flooring system having sub-panels with complementary edge patterns

a technology of complementary edge patterns and sub-panels, applied in the field of laminate materials, can solve the problems of prohibitively high materials and labor costs for installing such floors, and the alternative typically does not possess the realistic look and texture of traditional building and finishing flooring materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

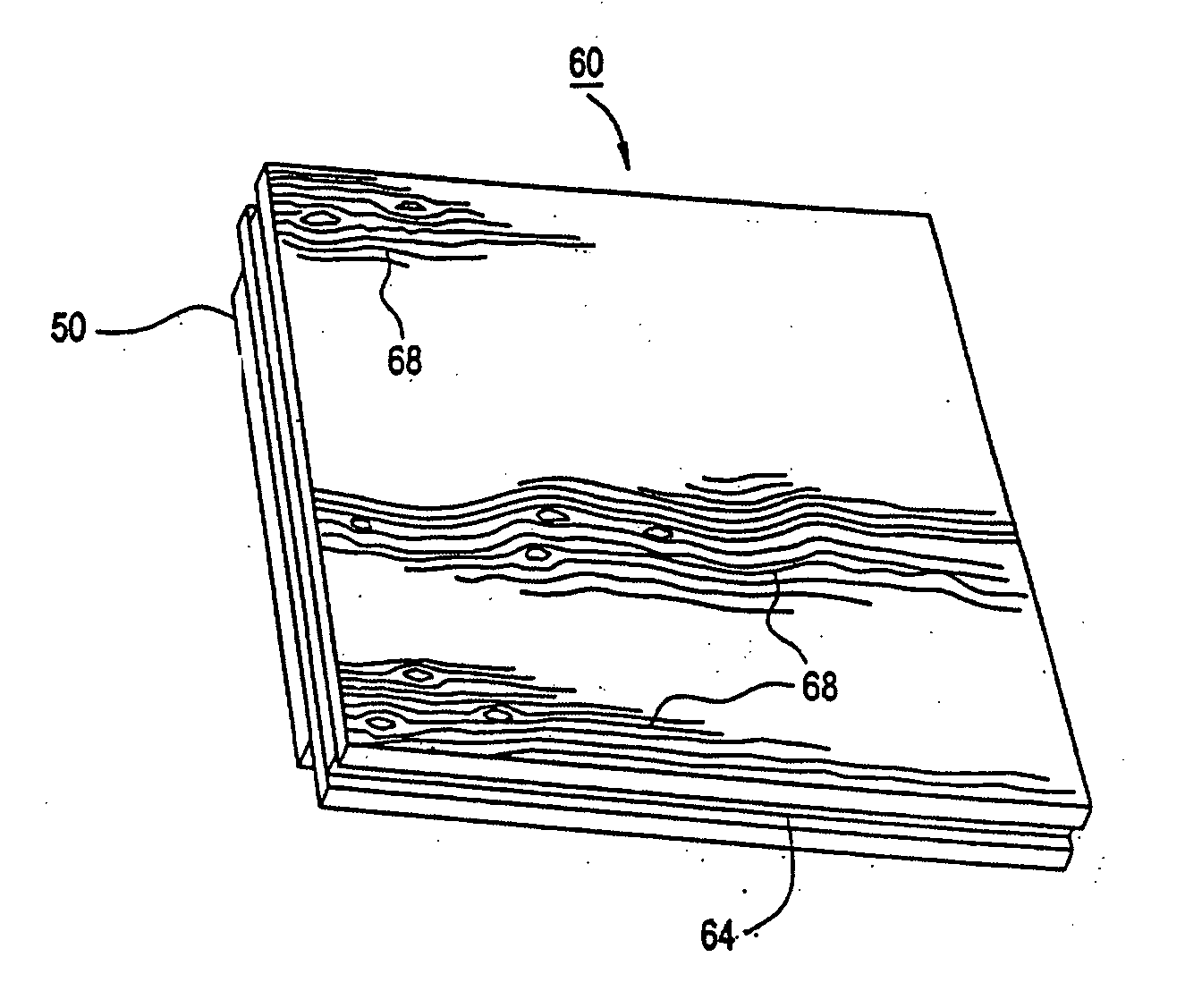

[0049]FIG. 5 generally illustrates components of a flooring plank according to the principles of the present invention.

[0050] Referring to FIG. 5, an embossed-in-registration flooring system may, for example, include at least one flooring plank. In one aspect of the present invention each flooring plank may include a board substrate 34 made out of a substrate material (e.g., a medium or high density fiberboard, chipboard, etc.), at least one base sheet 36 (e.g., a kraft paper sheet) impregnated with predetermined resins and arranged over and / or under the board substrate 34, a decorative paper sheet 38 about 0.15 mm thick and impregnated with a polymerizable resin (e.g., phenols such as melamine) arranged over the board substrate, and at least one protective overlay sheet 30 arranged over the decorative paper sheet 38. In one aspect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com