Cyclone type dirt separator and electric vacuum cleaner

a technology of electric vacuum cleaner and separator, which is applied in the direction of suction cleaner, reversed direction vortex, cleaning filter means, etc., can solve the problems of poor efficiency, short service life, and quick blockage of filter,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

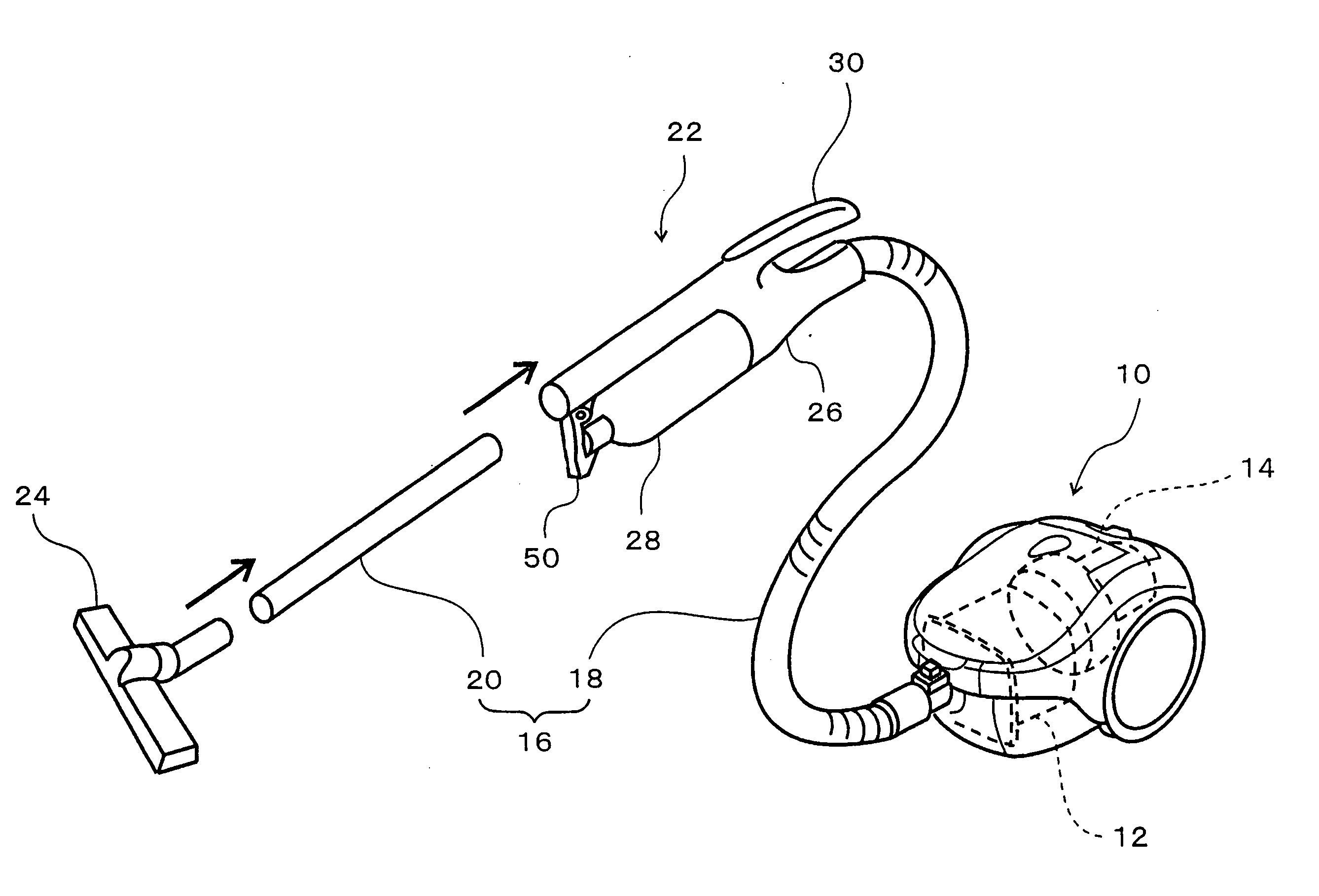

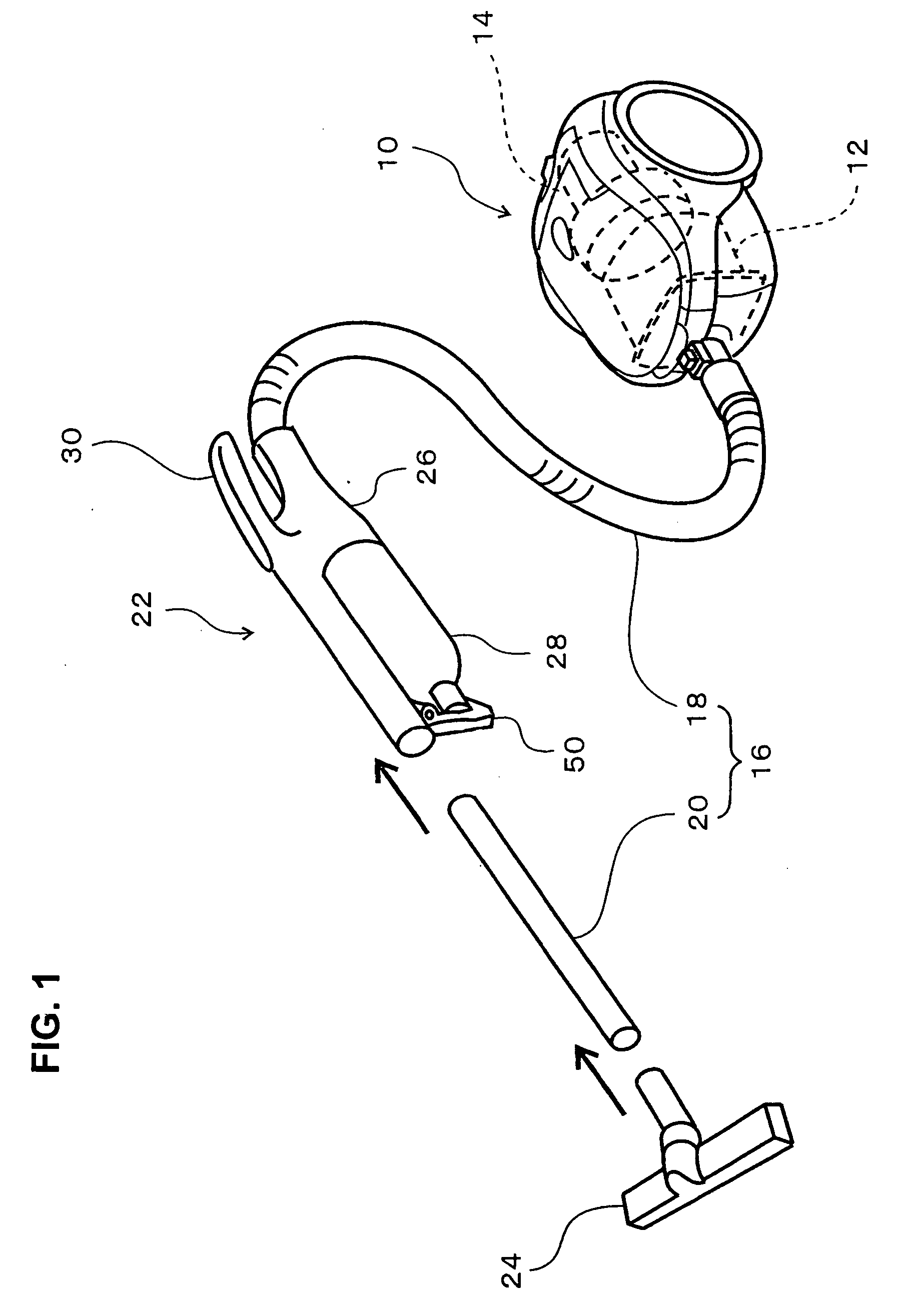

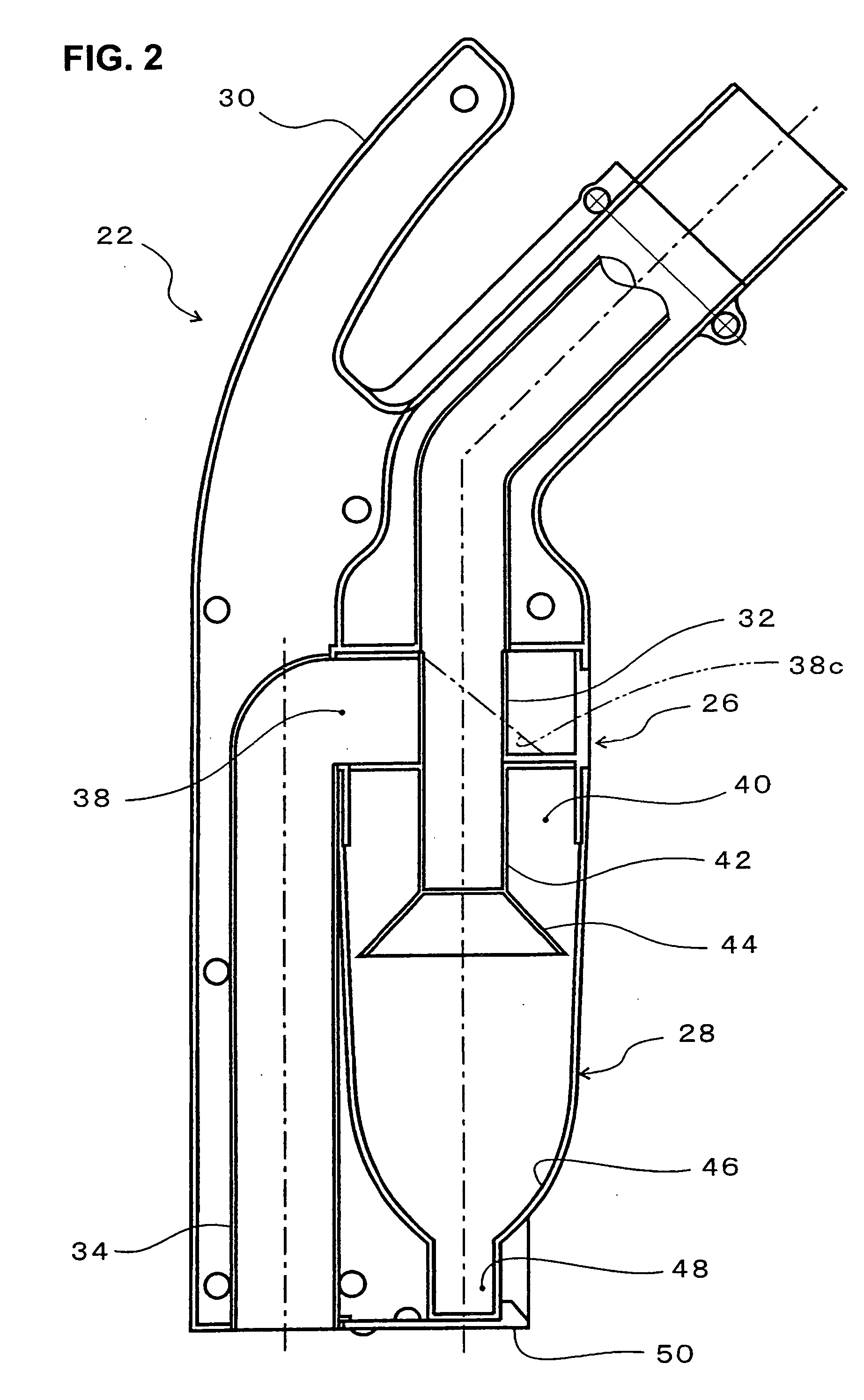

[0036] In FIG. 1, the reference numeral 10 is a cleaner main body, and this cleaner main body 10 is equipped with a filter 12 and an electrically driven air blower 14. A suction tube 16 connected to the cleaner main body 10 is comprised of a flexible tube 18 and an extension tube 20, and a cyclone type dirt separator 22 is provided at an intermediate point of this suction tube 16. The electrically driven air blower 14 generates a suction force by rotating a fan (not shown) at high speed with an electric motor (not shown).

[0037] The electric vacuum cleaner 10 is indeed usable without a cyclone type dirt separator 22; and in this case, the flexible tube 18 (or the forward end of the flexible tube 18) and the extension tube 20 (or the rear end of the extension tube 20) are directly connected to each other to form the suction tube 16. When a cyclone type dirt separator 22 is used, the cyclone type dirt separator 22 is interposed between the flexible tube 18 and the extension tube 20. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com