Glue filling device for liquid crystal panel manufacturing

A liquid crystal panel and glue filling technology, which is applied to the surface coating device, spray device, coating and other directions, which can solve the problems of air-drying glue, difficult handling of glue in the dispensing head, clogging and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

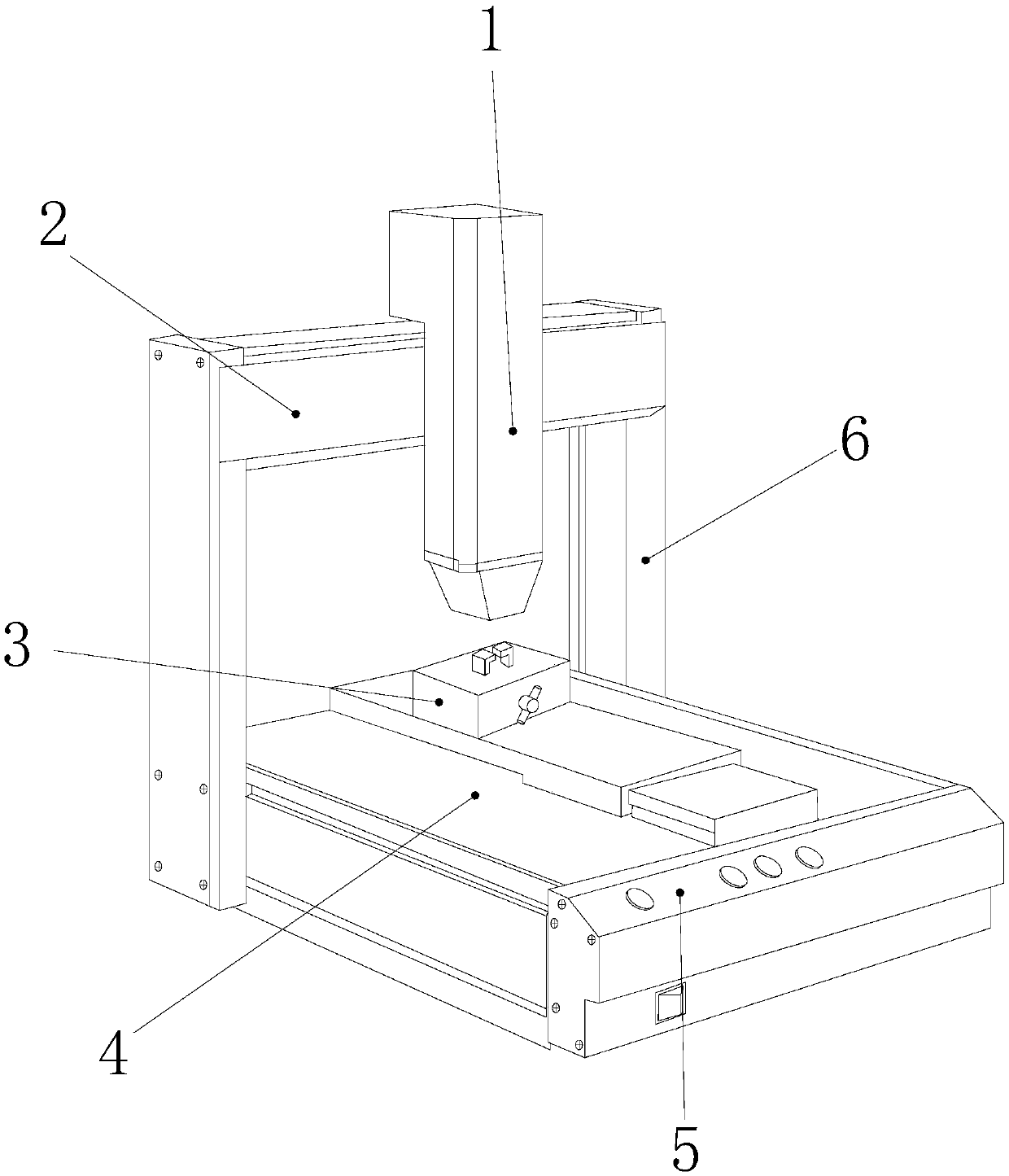

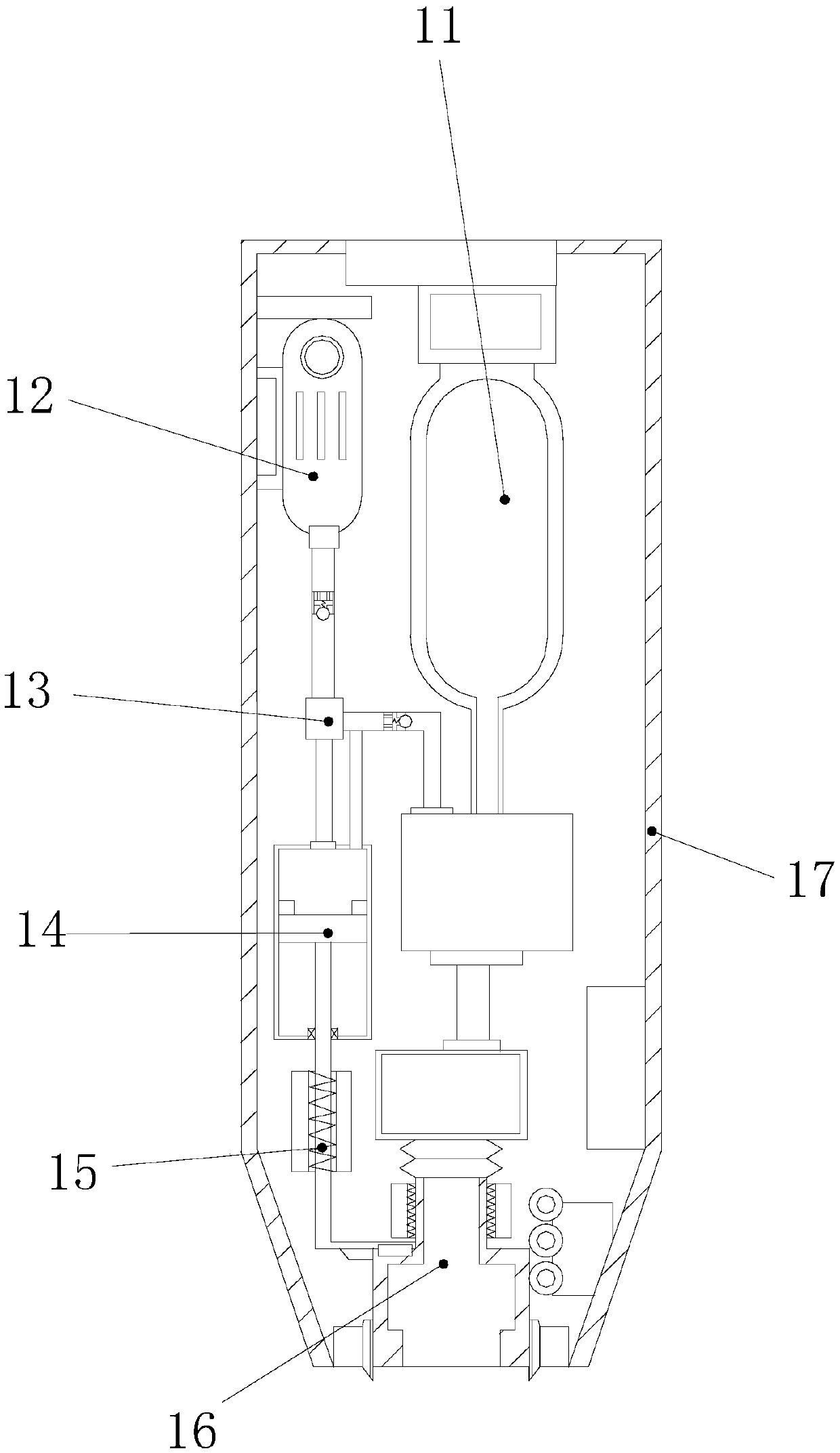

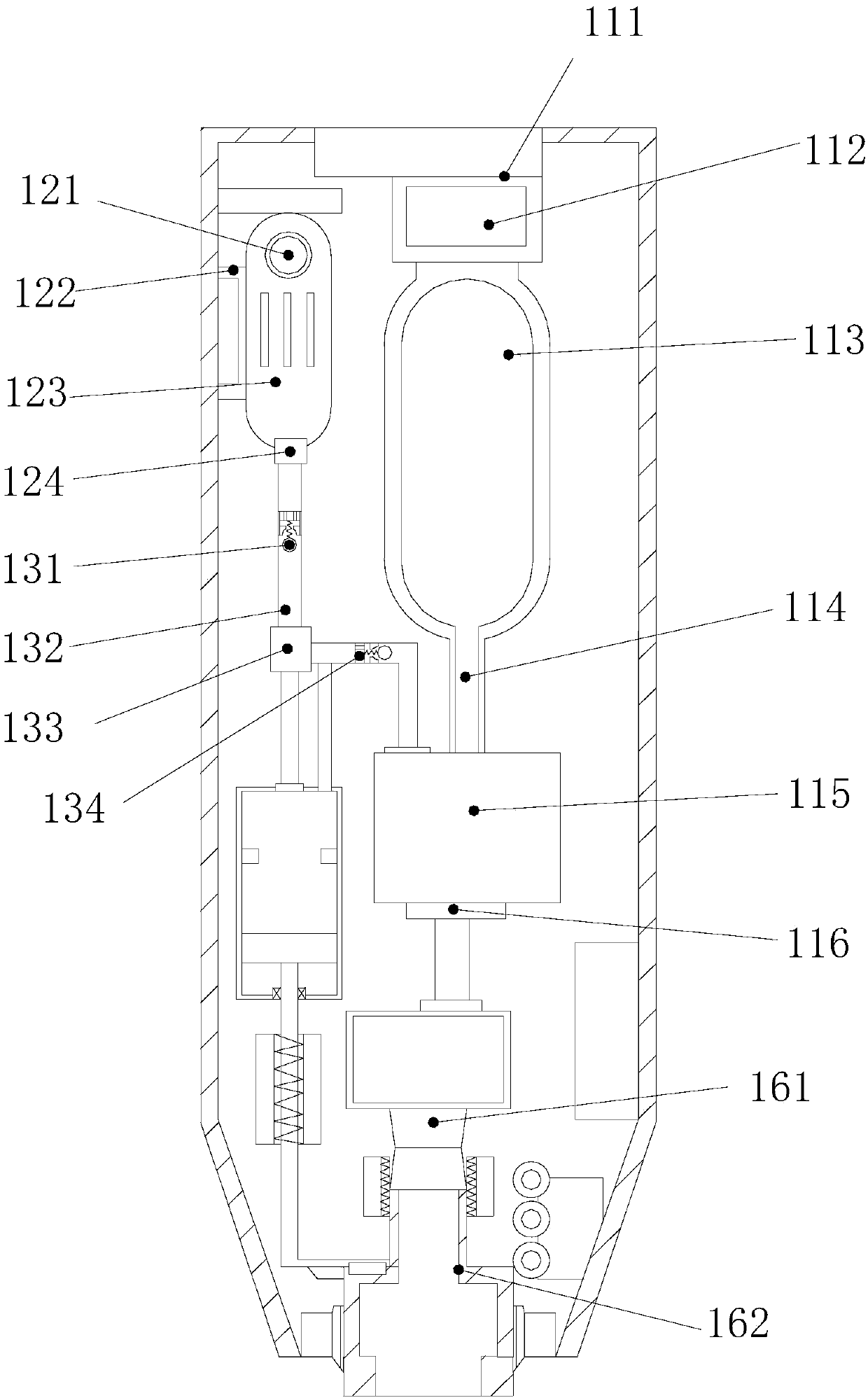

[0023] see Figure 1-Figure 5, the present invention provides a liquid crystal panel making glue potting device, its structure includes a potting device 1, a slide bar 2, a clamp 3, a workbench 4, an operator 5, a support rod 6, the rear end of the potting device 1 is connected to the sliding The front end of the rod 2 is movably connected, the bottom end of the sliding rod 2 is welded to the top of the support rod 6, the bottom end of the clamp 3 is welded to the top of the workbench 4, and the manipulator 5 is arranged on the workbench 4 and the two are integrated structures, the clamp 3 is located directly below the glue filling device 1, and the glue filling device 1 includes a liquid storage mechanism 11, a liquid feeding drive mechanism 12, a pneumatic splitter mechanism 13, a glue spraying mechanism Compensation mechanism 14, liquid filling head push-out mechanism 15, liquid filling head assembly 16, shell 17, the top of the liquid storage mechanism 11 is welded to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com