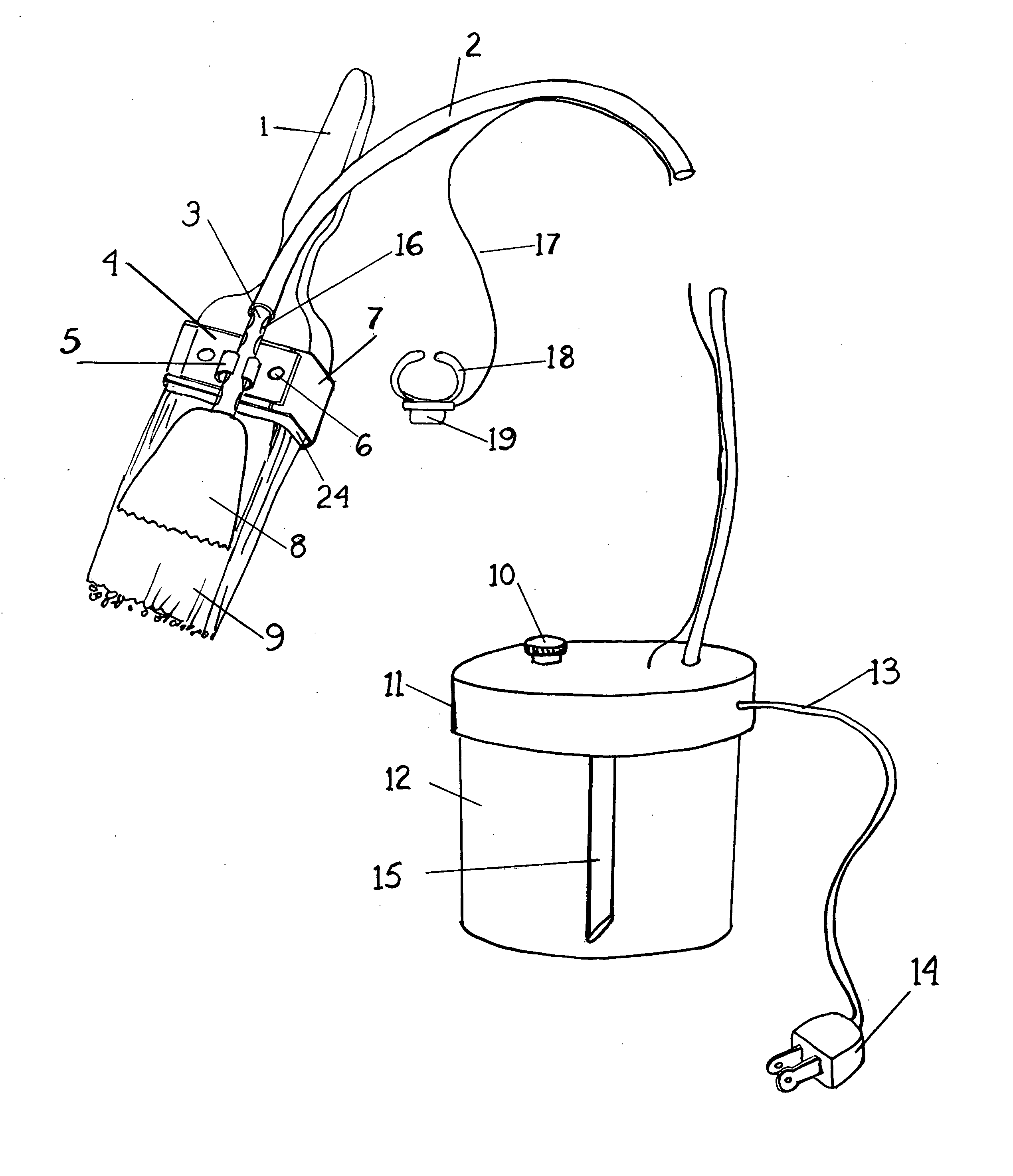

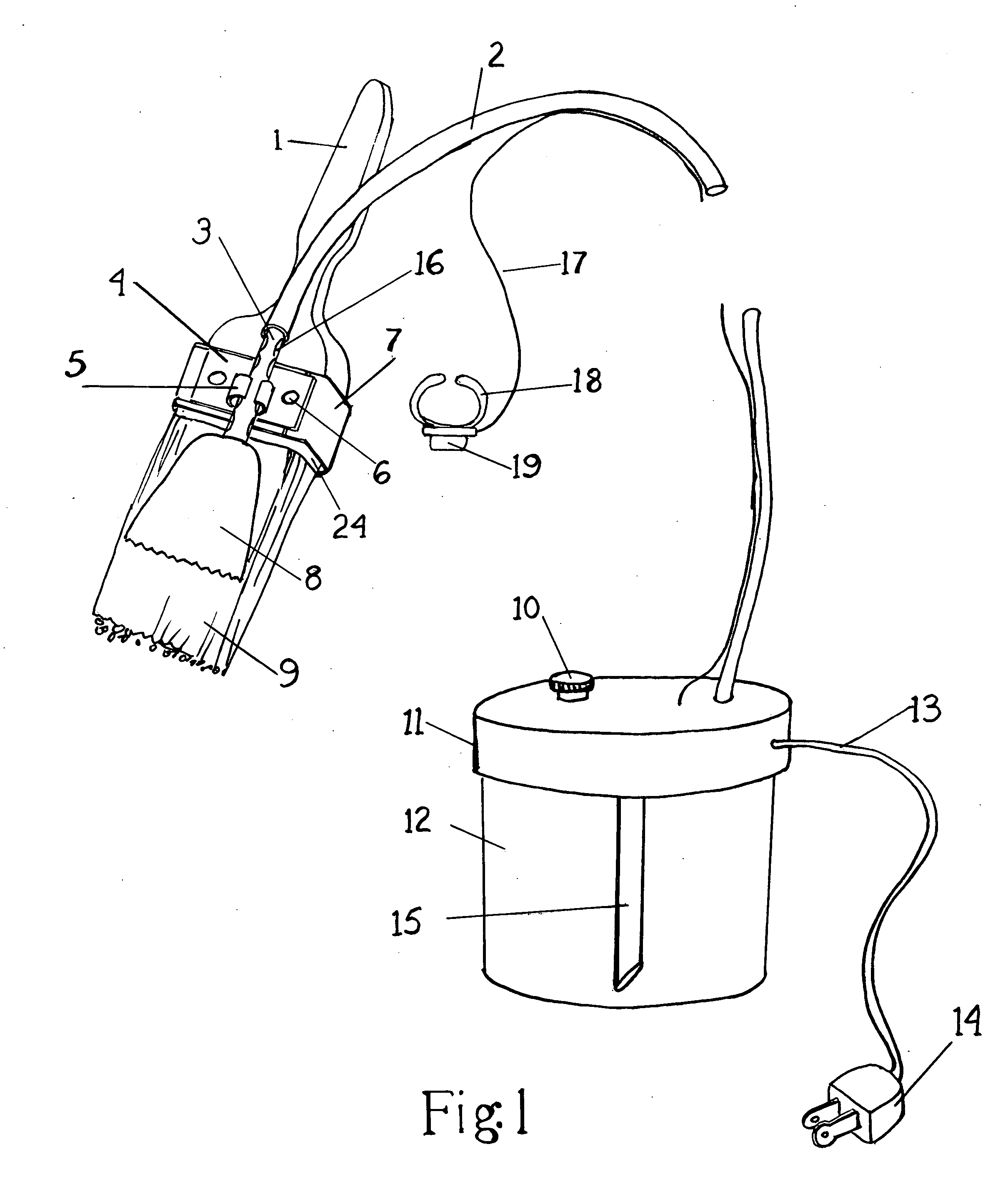

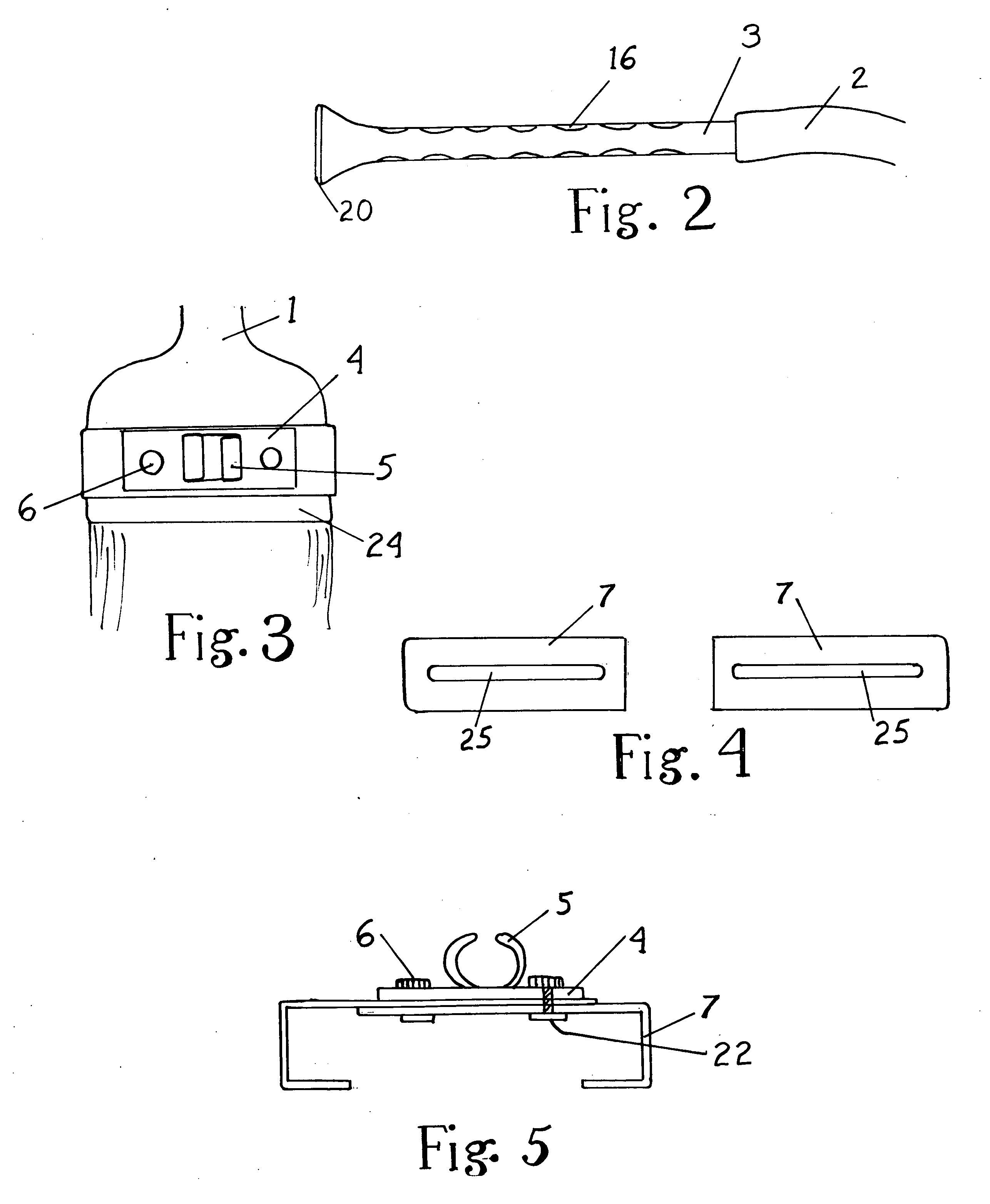

[0005] In the preferred embodiment, the invention consists of a number of interrelated members, that when joined together consist of a standard, off the shelf paint brush as is commonly found universally, consisting of a wooden or other material, handle, a metal or other material binding strap which secures the “brush” end, be it bristles, foam or other material to the handle, in addition a rigid, stationary platform of approximately two inches in length and one and one-quarter inches in width, which is placed and located on the “connecting strap” area of the paint brush. This stationary platform also features two internally threaded knobs at either end of the platform which can be turned on a screw, which projects from below the platform. This screw is an integral component of a disk-like boss at one end, the purpose of which is to pass through and engage a slot in two separate “J” shaped brush clamps, which are positioned below and contiguous to the stationary platform, the boss being below the brush clamp on each of the two sides. The purpose of the adjustable brush clamps is to provide the option of securing the device to brushes of differing widths, be it 2 inches, 2½ inches, four inches, etc. Additionally, the brush clamps could be conformed to retain a round-type brush such as a “sash tool”. When in use, the stationary platform is positioned onto the paint brush in the area of the “connecting strap” and the two brush clamps are firmly snugged against the sides of the brush, and then the two nuts on the top of the platform are tightened onto the projecting screw, the boss engaging the underside of the brush clamps, thus providing a secure, friction-type retention of the stationary platform to the brush itself, both from top to bottom and side to side. The purpose of securing the stationary platform to the paint brush in this manner is to provide a secure, stable surface for a rigid, removable tube, which is itself attached to the platform via a pair of centrally located, semi-circular retaining clips, these clips being an integral part of the stationary platform. The tube itself has a series of concentric depressions which interlock and engage the tube with the platform retaining clips. These “detents” in the tube allow the tube to be firmly positioned along the longitudinal axis of the brush at the operator's discretion. The aforesaid tube is of such construction that a length of some of the tube projects beyond the stationary platform onto the handle area of the brush and at its termination, acts as a receiving end for another flexible tube. This secondary flexible tube acts as a connector and paint transfer vehicle from its termination at one end of the rigid tube at the paint brush, continuous to and connecting to a vessel, which itself contains a volume of paint at some distance from the brush. The other termination of the rigid, removable tube features a flattened, ovoid aperture, the whole of which is triangular in appearance, when viewed from the top surface. The purpose of this aperture is to distribute a volume of paint, which itself has been delivered to this point from the distant paint vessel, via the flexible connecting tube to the opposite end of the rigid tube. The triangular-shaped aperture serves two distinct functions, i.e., that of restricting the flow of the paint, via the narrowed opening and also providing a wider, fan-like paint distribution pattern. Furthermore, the triangular-shaped terminus of the rigid, removable tube is positioned on the top surface of the “bristle” end of the paint brush in such a manner as to deliver a controlled volume of paint onto the bristles, foam, or other material of the brush. This paint volume is then allowed to penetrate into the brush surface, however, the position of the triangular-shaped terminus of the rigid tube in relation to the “bristles” in no way interferes with the flexing of the bristles nor their action of spreading the paint onto the to-be-painted surface. Furthermore, there is another fan-shaped structure or member also known as the “distribution apron”, that consists of a flat, triangular array of bristles, foam or other material, which is separately bound together and attached to an integral pair of semi-circular clips on its underside. These clips engage the rigid, removable tube in an area of the tube somewhat in between the triangular-shaped tube terminus and the tube's own attachment to the stationary platform clips. The purpose of this additional structure or member is twofold, that is, in one instance, this member acts as a “paint shield”, in preventing the paint which has been delivered to the brush surface via the rigid removable tube from dripping away from the brush, as the paint is thus confined between its structure or member and the brush surface itself, should the brush be turned over in the hand of the operator, and, more importantly, the structure of distribution apron, whether fabricated out of brush-like bristles, a triangular piece of foam or flexible plastic-like material, both having a series of fan-shaped ridges on its underside, acts to distribute the paint in a fan-like pattern over a larger width of the bristle area and closer to the working ends of the bristles. In addition, this structure or memb

Login to View More

Login to View More  Login to View More

Login to View More