Motor control circuit for supplying a controllable driving current

a technology of motor control circuit and driving current, which is applied in the direction of electric controller, motor/generator/converter stopper, dynamo-electric converter control, etc., can solve problems such as excessive disturbance, and achieve the effect of suppressing the noise of driving curren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments according to the present invention will be described in detail with reference to the drawings.

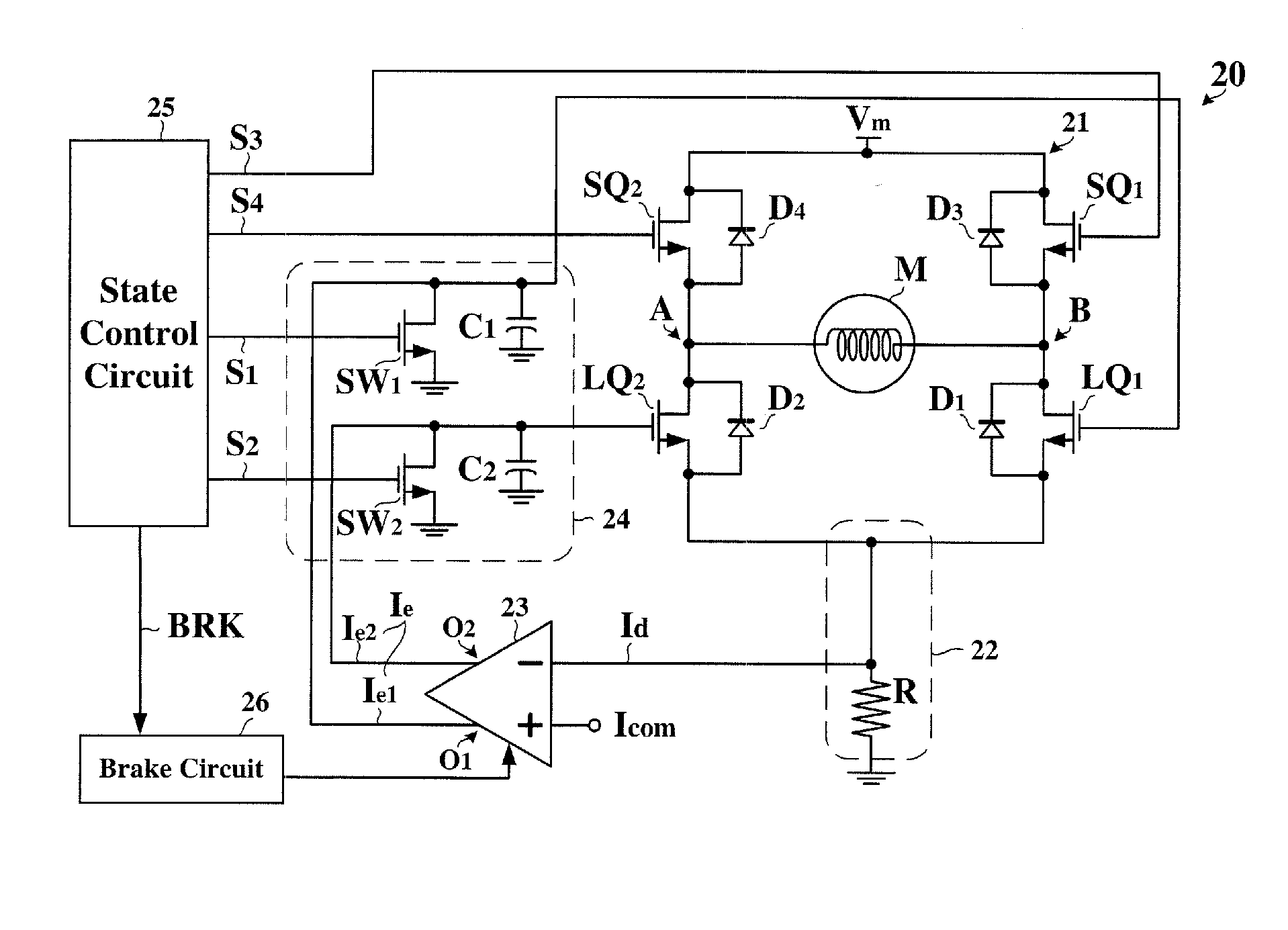

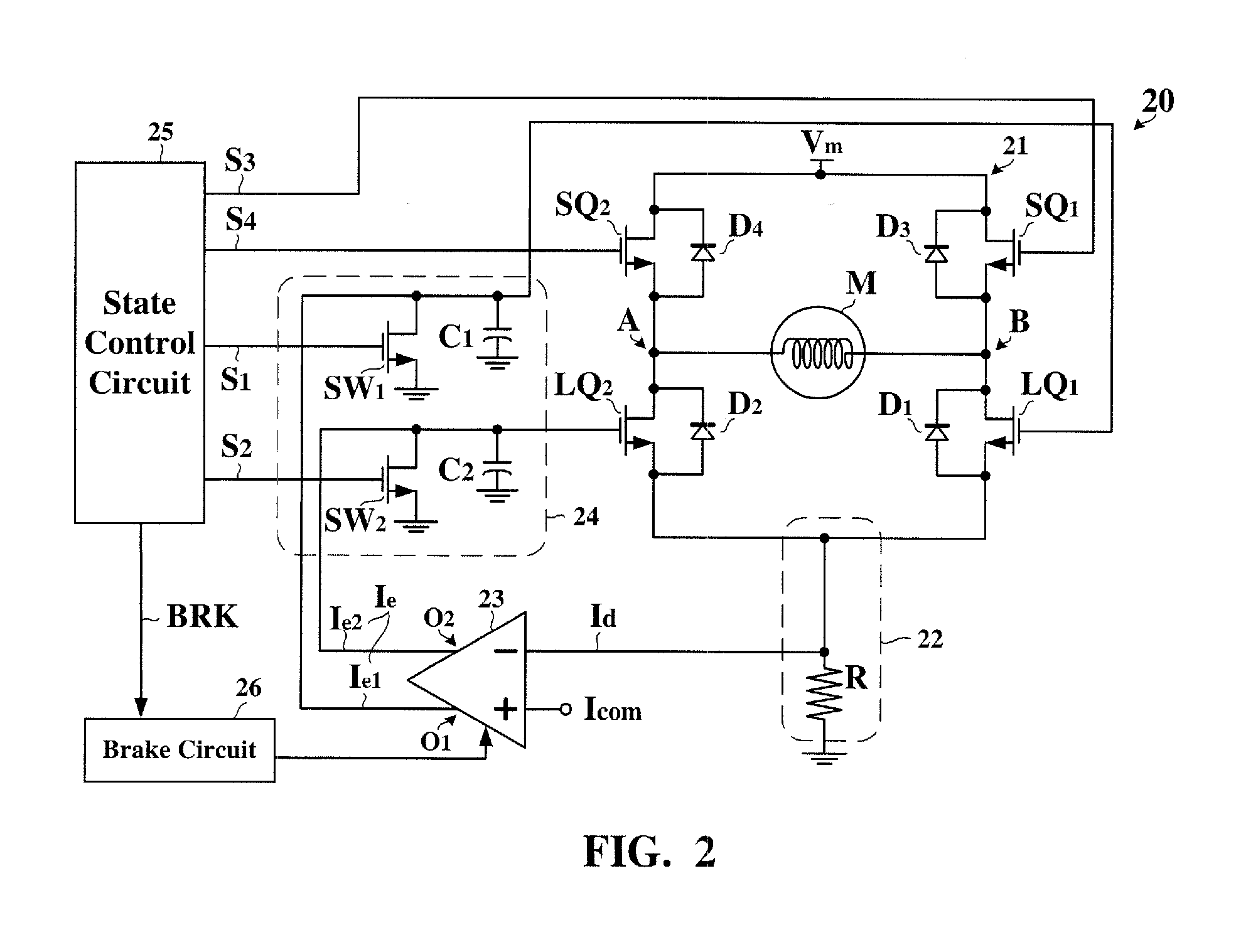

[0030]FIG. 2 is a circuit diagram showing an example of a motor control circuit 20 according to the present invention. Referring to FIG. 2, the motor control circuit 20 includes an H-bridge circuit 21, a current detection circuit 22, an error amplifier 23, a feedback circuit 24, and a state control circuit 25.

[0031] The H-bridge circuit 21 includes two switching units SQ1 and SQ2 and two linear units LQ1 and LQ2 The switching units SQ1 and SQ2 couple a supply voltage source V and a motor M while the linear units LQ1 and LQ2 couples the motor M and a ground potential. The switching units SQ1 and SQ2 may be operated in a conductive mode and a nonconductive mode while the linear units LQ1 and LQ2 may be operated in a linear mode in addition to the conductive mode and the nonconductive mode. The term “conductive mode” refers to an operational state in which an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com