Clean Air Toilet System-Tank "C.A.T.S-Tank"

a technology of toilet system and toilet tank, which is applied in the direction of water installation, lavatory sanitory, etc., can solve the problems of inefficiency of standard mechanical ventilation system, clogging of exhaust fan, and affecting the health of residents, so as to achieve less electricity, less cost, and improve the effect of air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

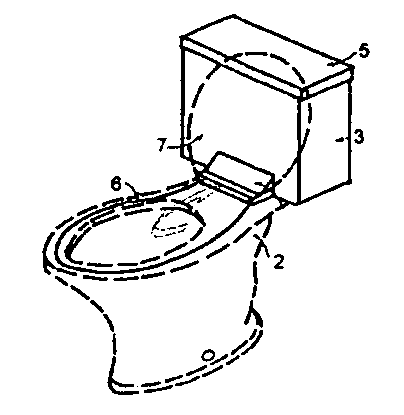

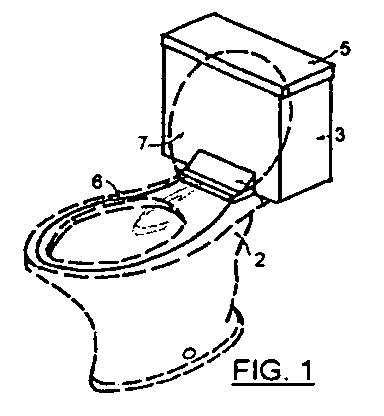

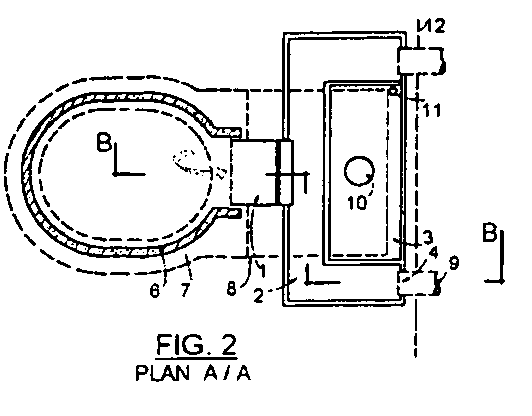

[0030] (1) Air Grille and Odor Filter Element (1) is located in front bottom of the C.A.T.S-Tank. The Air Grille and Odor Filter are built together in one element and are designed to: a) Exhaust the Odorous Air from the Toilet Bowl, before the odor spreads inside the bathroom. b) Clean the Odorous Air before it is released into the exterior environment. c) Protect the C.A.T.S-Tank from clogging. A large selection of materials are currently available for use: Sheet metal, ceramic, plastic, glass, rubber, wood or any other water proof materials which are easy to clean and quite strong. Air Filter is membrane type (nylon having micron sized holes).

[0031] Size: 100 mm. wide / 20 mm. height; Filter size: 100 mm. wide / 60 mm. height The distance between the Air Grille and the Odor Filter will vary depending on the toilet bowl and the toilet seat type. The Air Grille and Odor Filter may need to be replaced every 6 month. Air Grille and Odor Filter is a novel element with an unique function a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com