Oscillating water column wave energy converter incorporated into caisson breakwater

a technology of oscillating water column and wave energy converter, which is applied in the direction of caissons, water-power plants, buttress dams, etc., can solve the problems of inability to protect a port, inability to amplify waves, and dangers of overtopping discharg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

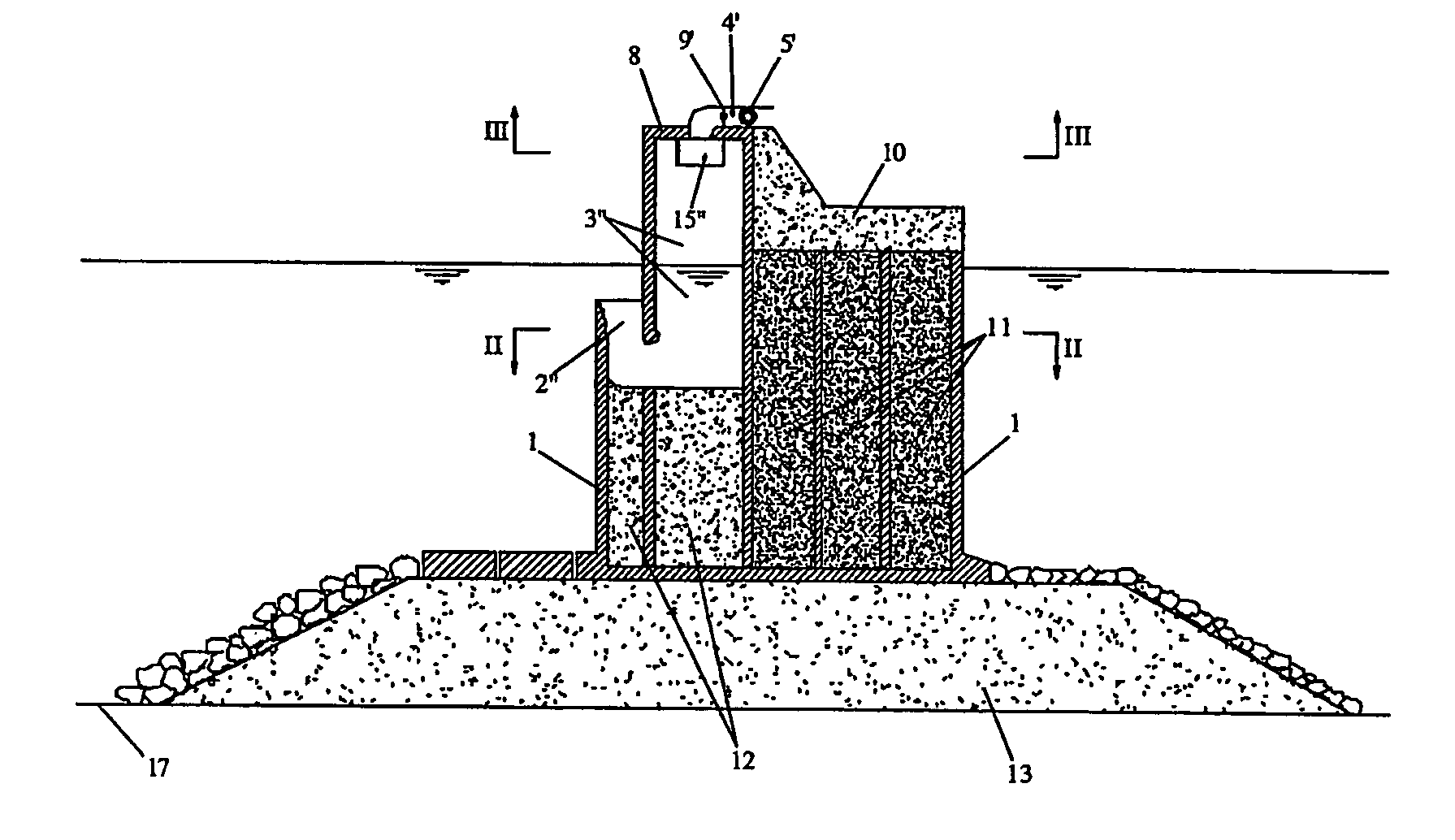

[0043] The breakwater of the present invention consists of caissons close to each other or joined together, like a conventional caisson breakwater. Like casssons of a conventional caisson breakwater, the caissons of the breakwater of the present invention (see FIGS. 2 to 12) typically rest on a rubble mound foundation 13 on the seabed 17, and a caisson 1 of the breakwater consists of cells which are filled with sand and / or gravel 11 and / or concrete 12. Like in a conventional caisson breakwater, a superstructure 10 is cast in concrete above each caisson.

[0044] In a first embodiment (FIGS. 2-3-4), some vertical stiffening-walls 14′,14″ subdivide the vertical duct into sections 2′,2″,2′″, and subdivide the room 3 into cells 3′,3″,3′″. Each of said cells 3′,3″,3′″ is connected with the atmosphere by its own air-duct 4′,4″,4′″ with self-rectifying turbines (e.g. Wells turbines) 5′,5″,5′″ and valves 9′,9″,9′″.

[0045] In a second embodiment (FIGS. 5-6-7), the vertical walls 14′,14″,14IV,1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com